Ways CNC Services Help Cut Manufacturing Expenses in 2025

CNC technology has revolutionized manufacturing by making processes faster, more precise, and cost-effective. Over the years, advancements like CAD/CAM software and automation have reduced human error and labor expenses. Today, CNC systems integrate AI and IoT to optimize production in real time, cutting manufacturing costs significantly. These innovations also support lean manufacturing by minimizing waste and improving efficiency. By adopting CNC machining, you can achieve substantial cost savings while maintaining high-quality standards in production.

Key Takeaways

CNC machines cut materials precisely, wasting less and saving money.

Using cheaper materials like aluminum or plastic helps save costs.

Simple part designs use less time and material, saving money.

Using standard parts means less custom tools and lower costs.

CNC automation lowers worker costs and boosts work speed, saving money.

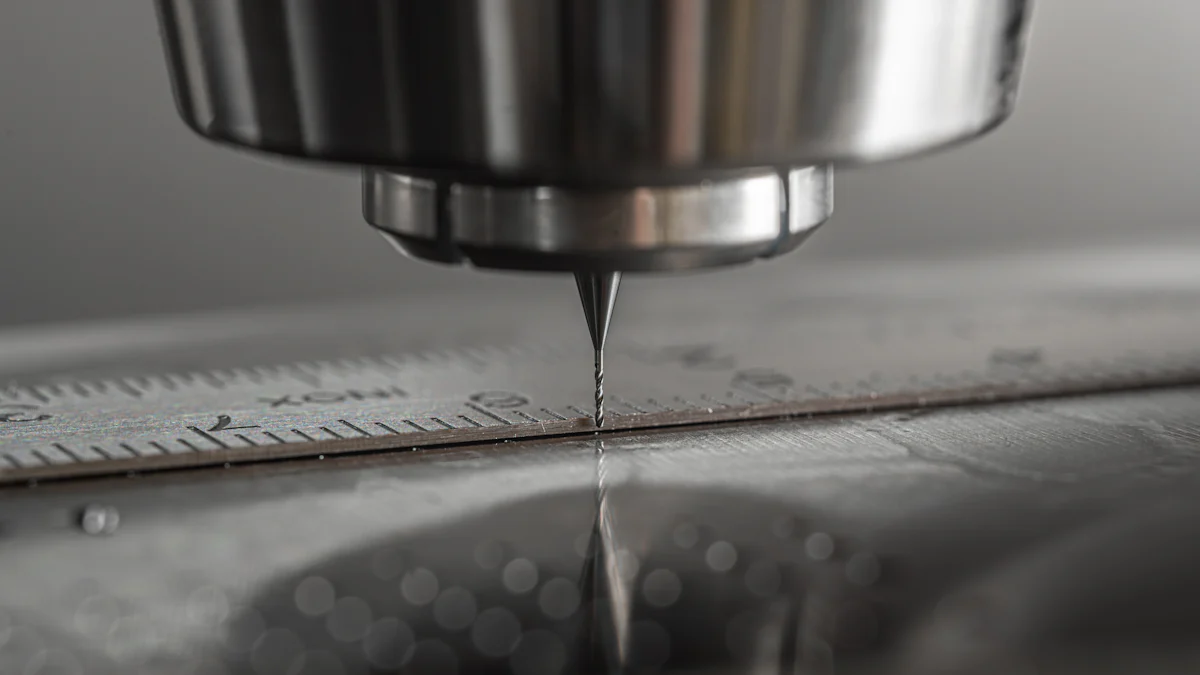

Material Efficiency in CNC Machining

Reducing Material Waste

CNC machining plays a vital role in helping you reduce material waste, which directly lowers manufacturing costs. Precision machining ensures that every cut is accurate, minimizing scrap and optimizing material usage. For example, CNC milling machines can cut parts with extreme precision, leaving very little excess material behind. This level of accuracy not only saves resources but also enhances the overall efficiency of your production process.

Efficient toolpath planning is another way CNC systems help reduce material waste. By optimizing the movement of cutting tools, CNC machines avoid unnecessary material removal. Techniques like nesting, where parts are strategically positioned on a workpiece, maximize material usage and minimize scrap. Additionally, lean manufacturing principles align production with demand, further reducing waste and costs. In some cases, scrap material can even be recycled into new stock, contributing to a more sustainable manufacturing process.

Tip: Reducing material waste not only saves money but also improves your environmental impact. Lower waste levels reduce energy consumption and help preserve natural resources.

Selecting Cost-Effective Materials

Choosing the right materials for CNC machining is essential for balancing cost and performance. CNC machines support a wide range of affordable materials, allowing you to select options that meet your budget and functional requirements. For instance, aluminum offers excellent machinability and corrosion resistance, making it ideal for industries like aerospace and automotive. Plastics, on the other hand, are lightweight and cost-effective, suitable for applications requiring electrical insulation or chemical resistance.

Material | Characteristics | Applications |

|---|---|---|

Aluminum | Excellent machinability, lightweight, corrosion resistance | Aerospace, automotive, consumer electronics |

Stainless Steel | High corrosion resistance, strength, harder to machine | Medical devices, food processing, marine |

Tool Steels | Hardness, wear resistance, requires specialized tools | Cutting tools, molds, dies |

Plastics | Ease of machining, lightweight, cost-effective | Electrical insulation, chemical resistance |

To optimize CNC machining costs, consider factors like material availability, lead times, and machining requirements. Balancing material properties such as strength, durability, and corrosion resistance with your budget constraints ensures cost-effective production. Simplifying part designs and using standardized components can also reduce costs by eliminating the need for custom tooling.

Note: Selecting recyclable materials can offset future raw material costs and contribute to a more sustainable manufacturing process.

Design Optimization to Reduce CNC Machining Costs

Simplifying Part Designs

Avoiding complex features like thin walls and deep pockets.

Simplifying part designs is one of the most effective ways to reduce cnc machining costs. Avoiding intricate features such as thin walls, deep pockets, or sharp internal corners can significantly lower machining time and material waste. Complex geometries often require specialized tools and slower cutting speeds, which increase costs. By focusing on straightforward designs, you can streamline the manufacturing process and improve precision.

For example, a case study showed that using advanced CNC software to simplify designs reduced labor expenses and sped up production timelines. This demonstrates how simplifying part designs can enhance production efficiency while cutting costs. If you encounter challenges like thin walls or tight tolerances, solutions such as adjusting cutting parameters or reinforcing critical areas can help maintain quality without increasing expenses.

Streamlining designs to reduce machining time and costs.

Streamlined designs not only save time but also improve production efficiency. Reducing unnecessary features minimizes the number of machining steps required, which directly lowers cnc machining costs. Early collaboration with your design team and suppliers can identify opportunities to simplify parts while maintaining functionality. Using advanced CAD/CAM software allows you to detect potential issues early, ensuring a smoother production process.

Tip: Simplified designs often lead to fewer errors during machining, reducing waste and improving overall efficiency.

Standardizing Components

Using standard sizes and shapes to lower custom machining needs.

Standardizing components is another powerful strategy to reduce cnc machining costs. By using common sizes and shapes, you can eliminate the need for custom tooling and reduce machine setups. This approach also allows you to leverage bulk purchasing of materials, which lowers overall manufacturing costs. For instance, adopting standard tooling facilitates faster changeovers, enhancing production efficiency and saving time.

Standardized components simplify the machining process.

Common designs reduce the need for custom tooling.

Readily available materials improve production efficiency.

Enhancing compatibility and reducing assembly costs.

Standardized components not only simplify machining but also enhance compatibility during assembly. This reduces the complexity of the manufacturing process and minimizes assembly costs. Using commercially available off-the-shelf (COTS) parts accelerates production timelines and reduces material expenses. Additionally, bulk purchasing of standardized parts optimizes material usage and decreases waste.

Note: Standardized components improve precision and reduce errors during assembly, leading to higher-quality products at a lower cost.

Labor and Time Savings with CNC Technology

Automation and Reduced Labor Costs

CNC machines revolutionize manufacturing by operating with minimal human intervention. Automation reduces labor costs by allowing machines to handle repetitive tasks without constant supervision. Features like automatic tool changers and robotic part loaders enable CNC systems to run continuously, even during breaks. This maximizes spindle utilization and ensures uninterrupted production.

You can also reduce your reliance on highly skilled labor. CNC machines are less dependent on operator expertise, as they deliver consistent results through precision and repeatability. This allows your skilled workers to focus on higher-value tasks, such as quality control or process optimization. By reallocating labor resources, you can improve production efficiency and achieve significant cost savings.

Tip: Investing in CNC automation may have a higher upfront cost, but the long-term savings from reduced labor costs and increased productivity make it a financially sound decision.

Faster Production and Prototyping

CNC technology accelerates production cycles by enabling continuous operation. Unlike manual machining, CNC machines can run 24/7 without breaks, dramatically increasing productivity. Automated processes optimize cutting speeds and material usage, reducing waste and enhancing production efficiency. This ensures you can meet tight deadlines without compromising quality.

Rapid prototyping is another area where CNC machining excels. The technology eliminates the need for molds, allowing you to produce accurate prototypes directly from digital designs. This reduces the time required for iterations and speeds up time-to-market for new products. Industries that rely on being first to market, such as consumer electronics, benefit greatly from this swift turnaround.

CNC machining also supports a wide range of materials, giving you flexibility in prototyping. Whether you need plastic for lightweight designs or metal for durability, CNC machines can handle it. The precision and repeatability of CNC systems ensure prototypes closely resemble final products, making them ideal for testing and validation.

Note: Faster prototyping not only reduces development time but also lowers cnc machining costs by avoiding the expenses associated with mass production errors.

Advanced Technology Benefits for Cost Savings

Predictive Maintenance and Downtime Prevention

Real-time monitoring prevents costly machine failures.

Predictive maintenance helps you avoid unexpected breakdowns by using real-time monitoring to track the performance of your CNC machines. Smart sensors collect data on vibrations, temperature, and other critical parameters. This allows technicians to identify potential issues before they escalate into costly failures. For example, vibration monitoring can detect misalignment or imbalance in rotary machines, while thermography highlights thermal anomalies that may indicate overheating. These techniques ensure your equipment operates within optimal conditions, reducing disruptions and improving production efficiency.

Studies show that predictive maintenance decreases unplanned downtime by 30% and reduces on-site repair time by up to 75%. By diagnosing problems early, you can keep your production running smoothly and avoid expensive repairs. This proactive approach also extends the lifespan of your machinery, further contributing to CNC machining cost reduction.

Proactive maintenance extends equipment lifespan.

Proactive maintenance strategies, such as regular inspections and nondestructive testing, help you maintain your CNC machines in peak condition. Techniques like ultrasonics and tribology allow you to detect wear and tear without dismantling equipment. This minimizes downtime and ensures your machines deliver consistent precision. By addressing minor issues early, you prevent them from turning into major problems, saving both time and money. Over time, this approach reduces waste and lowers your overall manufacturing costs.

Tip: Implementing predictive maintenance not only reduces downtime but also enhances the reliability of your production processes.

Data-Driven Efficiency

CNC software optimizes machining processes for cost savings.

Advanced CNC software uses data analytics to optimize machining processes, helping you achieve significant manufacturing cost savings. Smart sensors provide real-time feedback, enabling immediate adjustments to cutting speeds, tool paths, and material usage. This reduces waste and improves production efficiency. For instance, predictive algorithms analyze tool wear and recommend replacements before failures occur, ensuring uninterrupted operations.

Analytics improve production planning and resource allocation.

Data analytics plays a crucial role in improving resource allocation and production planning. By analyzing big data, you can identify bottlenecks, streamline workflows, and enhance supply chain management. Real-time monitoring ensures consistent product quality and allows for quick adjustments when needed. For example, accurate data helps you predict when tools require maintenance, optimizing schedules and reducing downtime.

Benefit | Description |

|---|---|

Accurate data for decision-making | Provides precise insights for better resource management. |

Real-time data monitoring | Maintains quality and enables quick corrective actions. |

Optimized machining parameters | Improves scheduling and reduces tool wear-related disruptions. |

Note: Leveraging data-driven insights ensures your production remains efficient and cost-effective.

Bulk Production and Scalability in CNC Machining

Economies of Scale

Lower per-unit costs with larger production volumes.

Scaling up production with CNC machining offers significant cost advantages. When you produce parts in bulk, fixed costs like setup and tooling expenses spread across more units. This reduces the cost per part, making large-scale production highly economical. For instance, increasing production volume from one to five units can cut the per-unit cost in half. Bulk material purchases also allow you to negotiate discounts, further lowering expenses.

CNC machining thrives in high-volume production due to its precision and repeatability. Each part matches the exact specifications of the design, ensuring consistent quality across large batches. This reliability minimizes waste and reduces the need for rework, saving both time and resources. By leveraging economies of scale, you can achieve lower costs while maintaining high standards of production.

CNC machines excel at consistent, repeatable manufacturing.

CNC machines are designed for repeatability, making them ideal for bulk production. Once programmed, they can produce identical parts with minimal variation, even in large quantities. This consistency eliminates errors that often occur in manual processes, ensuring uniformity in every unit. High-capacity CNC systems also allow you to automate processes, increasing efficiency and reducing labor costs. These features make CNC machining a cost-effective solution for scaling production.

Flexibility for Varying Production Needs

Adapting to both small and large orders for cost efficiency.

CNC machining offers unmatched flexibility, allowing you to adapt to both small and large production runs. Whether you need a single prototype or thousands of units, CNC machines can handle varying volumes without compromising quality. Digital templates guide the process, ensuring precision and reducing human error. This adaptability makes it easier to meet fluctuating demand while keeping costs under control.

CNC systems also support faster production cycles, enabling you to respond quickly to market changes. For example, industries with seasonal demand can scale up production during peak periods and scale down during slower times. This flexibility ensures you only produce what you need, minimizing waste and optimizing costs.

Reducing inventory costs through just-in-time production.

Just-in-time (JIT) production helps you reduce inventory costs by aligning manufacturing with demand. By producing parts only when needed, you avoid overstocking and free up storage space. This approach also shortens lead times, ensuring faster delivery to customers. Lean manufacturing principles, such as JIT, enhance efficiency and reduce waste, making your production process more cost-effective.

Production Volume | Cost Implications | Strategies to Optimize |

|---|---|---|

High Volume | Lower per-unit cost due to distributed setup expenses and bulk material purchases. | Invest in high-capacity CNC machines and automate processes. |

Medium Volume | Moderate per-unit cost with some economies of scale. | Use versatile machines and combine orders. |

Low Volume | High per-unit cost due to fixed setup expenses. | Simplify designs and use standard tooling. |

Prototype/One-Off Orders | Very high per-unit cost with custom tooling. | Use 3D printing for prototypes and flexible CNC machines for small batches. |

By combining JIT production with CNC machining, you can achieve cost efficiency while maintaining the flexibility to meet varying production needs.

CNC services offer a powerful way to reduce manufacturing costs while maintaining high-quality production. By leveraging advancements like AI-powered precision, IoT integration, and hybrid manufacturing, you can streamline operations and improve efficiency. These technologies also support sustainability by reducing waste and optimizing energy use. Flexible CNC systems adapt to varying production needs, ensuring cost-effective solutions for businesses of all sizes. As manufacturing evolves, adopting CNC machining will help you stay competitive and maximize profitability in 2025. Explore these innovations to future-proof your operations and achieve long-term success.

FAQ

What is CNC milling, and how does it reduce machining cost?

CNC milling is a machining process that uses computer-controlled tools to cut and shape materials. It reduces machining cost by improving precision, minimizing waste, and automating the machining process, which lowers labor expenses and increases efficiency.

How does cost reduction design improve manufacturing efficiency?

Cost reduction design focuses on simplifying part designs and using standard components. This approach reduces machining time, eliminates unnecessary features, and ensures manufacturable metal and plastic parts are easier to produce, leading to lower costs and faster production.

Why is automating the machining process important for cost-effectiveness?

Automating the machining process ensures consistent quality, reduces human error, and allows machines to operate continuously. This increases productivity and lowers labor costs, making it a cost-effective solution for both small and large-scale production.

How does CNC milling support lean manufacturing principles?

CNC milling aligns with lean manufacturing by minimizing material waste, optimizing tool paths, and enabling just-in-time production. These practices reduce excess inventory, improve resource utilization, and enhance overall cost-effectiveness.

What materials can CNC milling handle for manufacturable metal and plastic parts?

CNC milling supports a wide range of materials, including aluminum, stainless steel, tool steels, and plastics. This versatility ensures you can choose materials that balance performance and cost for your specific application.

See Also

Streamlined CNC Machining Solutions for Accurate Production Needs

Understanding CNC Technology: Innovations and Uses in Manufacturing

How CNC Precision Parts Impact Overall Manufacturing Expenses

Investigating CNC Machining Options for High-Precision Production

Uncovering Seven Major Advantages of CNC Machining in Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com