What is CNC Turning for CNC Machined Parts

CNC turning is a pivotal process in the realm of manufacturing, particularly in the creation of CNC machined parts. This technique involves the precise removal of material from cylindrical stock pieces, enabling the production of intricate components. The significance of CNC turning lies in its ability to craft parts with exceptional accuracy and complexity. Throughout this blog, key aspects such as the precision, versatility, and efficiency of CNC turning CNC machined parts will be thoroughly explored.

Understanding CNC Turning

In the realm of manufacturing, CNC turning stands out as a pivotal process that plays a crucial role in creating intricate CNC machined parts. The process involves the precise removal of material from cylindrical stock pieces, enabling the production of components with exceptional accuracy and complexity.

The CNC Turning Process

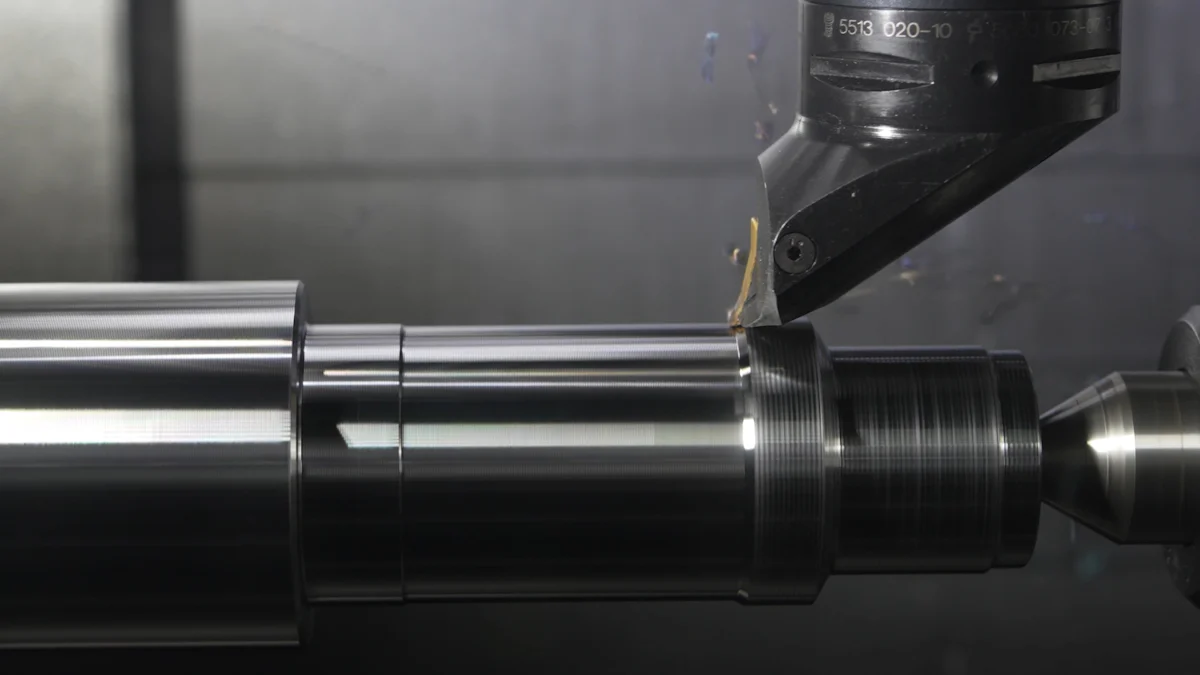

When delving into the intricacies of CNC turning, one encounters a meticulous process that revolves around two key aspects: Material Removal and Tool and Workpiece Interaction. The material removal phase entails cutting away excess material from the workpiece, shaping it into the desired form. Simultaneously, the tool and workpiece interact seamlessly to achieve precision and finesse in the final product.

Types of CNC Turning Machines

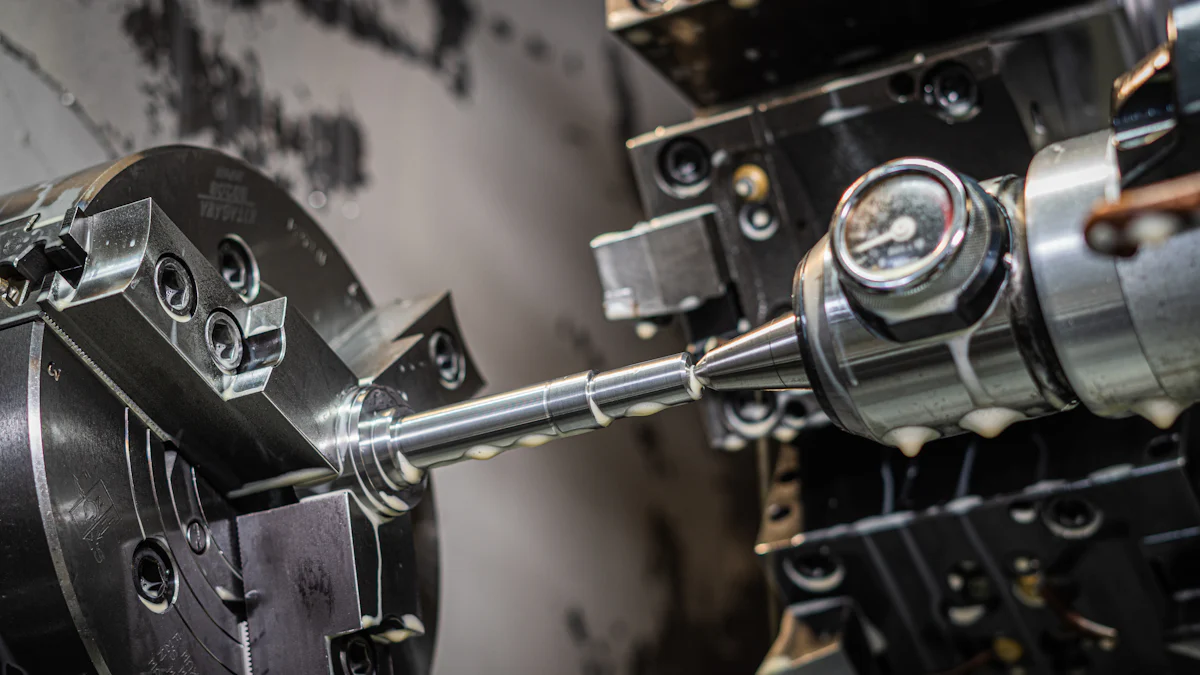

Within the domain of CNC turning, various machines come into play, each serving distinct purposes. These include Horizontal Turning Centers and Vertical Turning Centers, both offering unique advantages in terms of functionality and application.

CNC Turning CNC Machined Parts

In crafting CNC machined parts through CNC turning, two critical factors come to light: Precision and Accuracy and Versatility in Shapes and Sizes. The precision achieved through this method ensures that each component meets exact specifications with minimal room for error. Moreover, the versatility inherent in shaping parts allows for a wide range of shapes and sizes to be produced with utmost efficiency.

Applications of CNC Turning

In the Automotive Industry, Engine Components play a crucial role in ensuring the optimal functioning of vehicles. These components, crafted through CNC turning CNC machined parts, exhibit precision and durability, enhancing the overall performance of engines. Similarly, Transmission Parts are vital elements that facilitate seamless gear shifting and power transmission within vehicles.

Within the Aerospace Industry, Aircraft Components manufactured using CNC turning technology are characterized by their lightweight yet robust nature. These components undergo stringent quality checks to meet aviation standards, ensuring safety and efficiency in flight operations. Moreover, Spacecraft Parts demand intricate designs and high precision, making them ideal candidates for production through CNC turning CNC machined parts.

The utilization of CNC turning CNC machined parts extends beyond the automotive and aerospace sectors into diverse fields such as healthcare and manufacturing. In the realm of Medical Devices, precision is paramount to ensure accurate diagnosis and treatment. Through CNC turning, intricate components like surgical instruments and prosthetic devices can be fabricated with exceptional accuracy. Additionally, in the domain of Industrial Equipment, components produced via CNC turning exhibit superior strength and reliability, contributing to the seamless operation of machinery.

Advantages of CNC Turning

In the realm of manufacturing, CNC turning offers a myriad of advantages that elevate the production of intricate CNC machined parts to new heights. Let's delve into the key benefits that set CNC turning apart as a preferred method for crafting components with precision and efficiency.

High Precision

Achieving unparalleled precision is a hallmark of CNC turning, ensuring that each component meets exact specifications with utmost accuracy. The process guarantees Consistency in Production, where every piece mirrors the precise dimensions of its predecessors, maintaining uniformity across batches. By minimizing variations, manufacturers can uphold stringent quality standards and deliver flawless parts consistently. Moreover, the method significantly reduces the occurrence of errors caused by human intervention, enhancing overall operational efficiency.

Efficiency and Speed

Embracing CNC turning translates to faster production times without compromising on quality. The technology's automated nature expedites manufacturing processes, leading to swift turnaround times and increased productivity. With Faster Production Times, manufacturers can meet demanding deadlines while maintaining exceptional craftsmanship. Furthermore, the cost-effectiveness of CNC turning stems from its ability to optimize resources efficiently, reducing wastage and enhancing profitability.

CNC Turning CNC Machined Parts

The versatility offered by CNC turning extends beyond traditional machining methods, allowing for unparalleled freedom in design and functionality. Through material versatility, manufacturers can explore a wide range of materials suitable for diverse applications, from metals to plastics. This adaptability ensures that each part is tailored to its intended purpose with precision and durability. Additionally, the capability to craft complex geometries sets CNC turning CNC machined parts apart, enabling the creation of intricate shapes that push the boundaries of conventional manufacturing techniques.

In the realm of CNC machining, the importance of CNC turning cannot be overstated. The precision and versatility offered by this process pave the way for crafting intricate CNC machined parts with unparalleled accuracy. As industries evolve, future trends indicate a shift towards increased automation, high-mix low-volume manufacturing, and the integration of AI technologies. Embracing these advancements will not only enhance production capabilities but also drive sustainable practices in CNC manufacturing. With a focus on innovation and adaptability, CNC turning remains at the forefront of shaping the future of precision manufacturing.

See Also

Deciphering CNC Precision Machining: Unveiling CNC Turning Process

Proficiency in CNC Machining for Precision Component Production

Journey through CNC Machining Solutions for Precision Production

Understanding CNC Machining: Delving into Turning and Milling Methods

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com