Combining Additive Manufacturing and CNC for New Materials

Combining 3D printing and CNC machining is revolutionizing how you approach material innovation. This integration minimizes material waste, reduces tooling costs, and accelerates production speed. For example, 3D printing enables intricate designs, while CNC machining ensures precision. Industries like aerospace and automotive already use this hybrid approach to create lightweight components and next-generation materials. Imagine designing new materials with superior strength and durability by merging these technologies. How does this combination unlock such possibilities? Understanding this synergy could redefine how you manufacture and innovate.

Key Takeaways

Mixing 3D printing and CNC machining cuts waste and saves money. It makes manufacturing faster and better.

This method helps create tricky designs that old ways can't make. It boosts new ideas for making products.

Using both tools together makes parts stronger and last longer. This helps industries like airplanes and cars work better.

Hybrid manufacturing makes work easier and speeds up making new models. It helps companies make products faster to meet demand.

Using hybrid manufacturing lets people invent new materials. These materials can be made for special uses.

Understanding Additive Manufacturing and CNC Machining

What is Additive Manufacturing?

Key principles and processes of 3D printing

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer. The process begins with a design created using computer-aided design (CAD) software or by scanning an existing object. This design is then sliced into layers using specialized software. The 3D printer follows this framework to deposit material, forming each layer until the object is complete. The thickness of these layers can range from 10µm to 200µm, depending on the machine and settings. This layer-by-layer approach allows you to create intricate designs that would be impossible with traditional methods.

Advantages of additive manufacturing in material design

"With additive manufacturing, you produce — layer by layer — pretty much any geometry you want to create. You can create 3-D entities that are much more complex and have different material properties."

Additive manufacturing offers several advantages:

It enables the creation of complex geometries, such as hollow structures, without compromising strength.

You can improve part properties and produce lightweight components.

It supports rapid prototyping, allowing you to iterate designs quickly.

The process reduces material waste and energy consumption.

It facilitates customization and distributed manufacturing, making it ideal for both high and low-volume production.

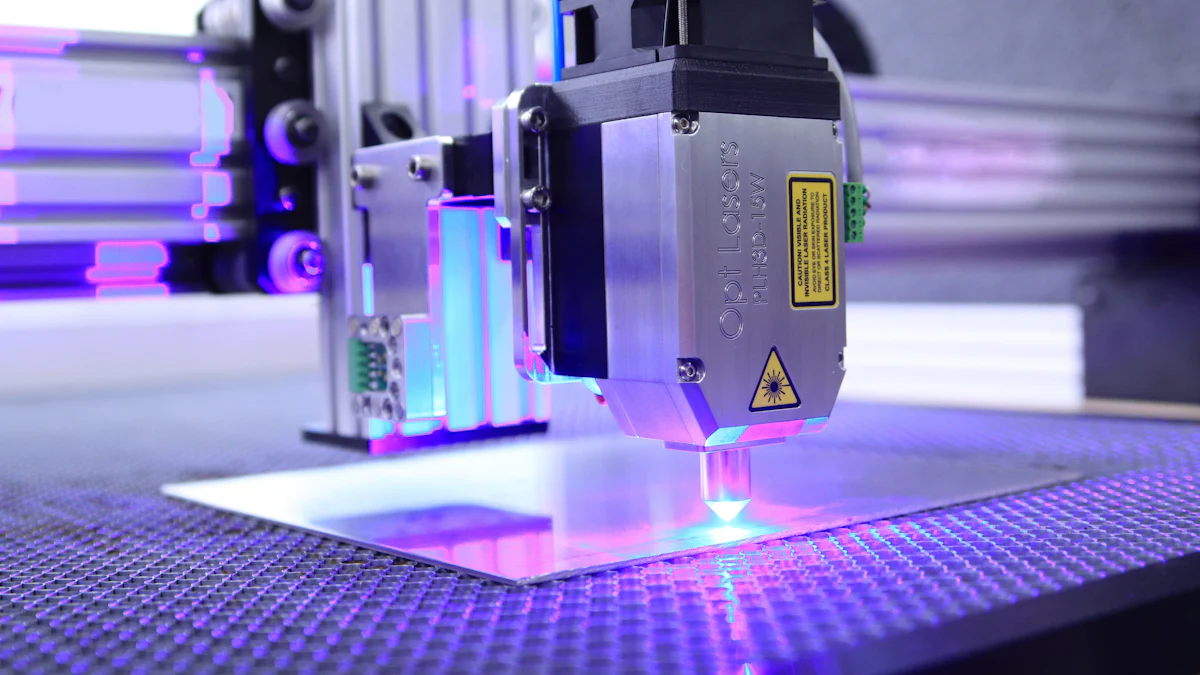

What is CNC Machining?

Overview of subtractive manufacturing processes

CNC machining is a subtractive process where material is removed from a solid block to create a part. Automated tools, guided by computer instructions, cut, drill, or mill the material with high precision. This method is ideal for industries requiring tight tolerances and intricate designs. CNC machining works well with metals, plastics, and even wood, making it highly versatile.

Precision and material compatibility in CNC machining

CNC machining achieves exceptional precision by cutting materials with sharp tools. The choice of material depends on its properties, such as hardness, toughness, and machinability. For example:

Hard materials like stainless steel maintain sharp edges during machining.

Tough materials, such as titanium, withstand energy without breaking.

Ductile materials, like aluminum, allow for shaping into complex designs.

This compatibility ensures you can create components that meet specific strength and durability requirements.

Comparing Additive Manufacturing and CNC

Differences in approach: additive vs. subtractive

Feature | CNC Machining | Additive Manufacturing |

|---|---|---|

Process | Subtractive (removes material) | Additive (adds material layer by layer) |

Dimensional Accuracy | Superior dimensional accuracy for tight tolerances | Less accurate compared to CNC |

Production Speed | Faster for high-volume production | Slower, but excels in rapid prototyping |

Material Versatility | Works with metals, plastics, and wood | Primarily plastics and resins, expanding to metals |

Common Applications | Automotive, aerospace, medical | Prototyping, complex geometries |

Complementary strengths of the two technologies

When combined, additive manufacturing and CNC machining bring out the best in each other:

Additive manufacturing creates near-net-shape parts with complex geometries. CNC machining refines these parts for precision.

The hybrid approach minimizes material waste and reduces production costs.

You can rapidly prototype with 3D printing and finalize designs with CNC machining, saving time.

This combination produces optimized parts that meet both mechanical and aesthetic requirements, especially in industries like aerospace.

Benefits of Combining Additive Manufacturing and CNC

Enhanced Design Flexibility

Ability to create complex geometries with precision

You can achieve unparalleled design flexibility by combining additive manufacturing and CNC machining. Start with metal 3D printing to create a near-net-shape part with intricate internal structures or complex geometries. Then, refine the part using CNC machining to meet precise tolerances and achieve smooth surface finishes. This hybrid approach allows you to push the boundaries of traditional design limitations. For example, you can produce intricate lattices or fluid channels that conventional methods cannot replicate. By leveraging the strengths of both additive and subtractive machining, you can innovate like never before.

Combining additive and subtractive techniques for intricate designs

The synergy of additive and subtractive techniques enables you to create high-quality parts with unmatched precision. Additive manufacturing provides the freedom to design complex shapes, while CNC machining ensures the final product meets exact specifications. This combination fosters innovation by allowing you to produce designs that were once impossible, such as components with internal cavities or multi-material structures. Whether you’re working on aerospace components or medical devices, this hybrid manufacturing process ensures both creativity and accuracy.

Cost and Time Efficiency

Reducing material waste through hybrid processes

Hybrid manufacturing reduces material waste by combining the efficiency of 3D printing with the precision of CNC machining. Additive manufacturing builds parts layer by layer, minimizing excess material. CNC machining then removes only what’s necessary to refine the part. This streamlined process not only saves resources but also lowers production costs. By eliminating non-value-added steps, you can focus on creating high-quality parts without unnecessary expenses.

Streamlining production workflows

The multitasking capabilities of hybrid systems simplify your manufacturing process. CNC machines can handle job setting and material handling efficiently, reducing machining time. This integration allows you to produce parts faster while maintaining quality. For example, hybrid manufacturing eliminates the need for separate setups, enabling you to move seamlessly from 3D printing to CNC machining. This streamlined workflow saves time and boosts productivity, making it ideal for industries that demand quick turnarounds.

Improved Material Properties

Development of new composites and multi-material parts

Hybrid manufacturing opens the door to innovative materials. For instance, you can create steel components with embedded copper to enhance thermal conductivity. This process involves using metal 3D printing to build the part and CNC machining to refine it. You can also design parts with stress-resistant areas while using cost-effective materials in non-critical sections. These advancements allow you to tailor materials to specific applications, improving performance and reducing costs.

Achieving superior strength, durability, and functionality

You can enhance the mechanical properties of your parts through hybrid manufacturing. CNC machining removes defects and residual stresses from 3D printed parts, improving their strength and wear resistance. This process also enables the creation of complex geometries, such as lattice structures, that enhance functionality. Additionally, hybrid systems allow you to repair expensive components by adding precise material layers. This versatility ensures your parts meet the highest standards of durability and performance.

How Hybrid Manufacturing Works

Hybrid Manufacturing Machines

Overview of machines that integrate additive and CNC capabilities

Hybrid manufacturing machines combine additive manufacturing and CNC machining into a single system. These machines streamline the manufacturing process by integrating forming, fusing, and finishing operations. They also offer advanced features like embedded sensing capabilities, which allow you to create smart products with self-regulating properties. Additionally, these machines enhance design possibilities, enabling you to produce intricate internal structures and complex geometries that traditional methods cannot achieve.

Key features of hybrid manufacturing machines include:

Cladding for multimaterial options, enabling high-performance components.

Directed energy deposition (DED) for repairs and rapid prototyping.

Quality assurance through in-situ monitoring to minimize defects.

CNC multitasking capabilities for improved accuracy and reduced production time.

Examples of commercially available hybrid systems like the Hybrid 3

Several hybrid systems are available today. For instance, the SmartZavod GENx system combines multi-material polymer 3D printing with CNC machining. This system allows you to create complex geometries while minimizing waste. Another example is Mazak's hybrid platforms, which integrate laser metal deposition with subtractive machining. These systems are widely used in industries like aerospace and automotive for repairing and enhancing metal components.

Process Workflow

Step-by-step explanation of a hybrid manufacturing process

A hybrid manufacturing process typically follows these steps:

Begin with additive manufacturing to create a near-net shape part.

Alternate between additive and subtractive steps to refine the design.

Use CNC machining for precision finishing and achieving tight tolerances.

Implement in-situ monitoring systems to ensure quality and correct defects during production.

This workflow allows you to address design complexities in real-time while maintaining high precision and efficiency.

Challenges and solutions in combining the two technologies

Combining additive manufacturing and CNC machining presents challenges like material waste, tooling costs, and surface finish issues. You can address these by optimizing the workflow to minimize waste and using advanced monitoring systems to improve quality. Additionally, hybrid machines reduce the need for custom tooling, saving both time and money.

Case Studies

Real-world examples of hybrid manufacturing in action

Hybrid manufacturing has proven successful in industries like aerospace and automotive. For example, Oak Ridge National Laboratories uses Mazak's hybrid platforms to produce and repair metal components. Similarly, Idaho National Laboratory employs hybrid machines to recreate parts for legacy nuclear reactors.

Success stories in material innovation

The STIM-MC project demonstrates how hybrid manufacturing bridges the gap between design and production. By combining 3D printing and injection molding, this project enables faster and cheaper prototyping. It also allows you to use a wider range of materials, including metals and ceramics, for innovative applications.

Applications Across Industries

Aerospace

Lightweight materials and complex components

Hybrid manufacturing is transforming aerospace engineering by enabling the creation of lightweight materials and intricate components. You can use this technology to produce parts with reduced weight and enhanced performance. For instance:

Airbus plans to 3D print 30 tons of metal parts monthly, including brackets and structural components, to improve lightweight designs.

General Electric aims to manufacture 25,000 LEAP engine nozzles using hybrid 3D printing, potentially reducing aircraft weight by over one ton.

Made in Space is developing a hybrid 3D printer for use in space, capable of creating complex geometries with various materials, including metals.

These advancements allow you to design components that meet the aerospace industry's rigorous demands for strength, durability, and weight reduction.

Examples of aerospace companies using hybrid manufacturing

Several aerospace companies are leading the way in hybrid manufacturing:

Airbus: Uses hybrid systems to produce lightweight metal parts for aircraft.

General Electric (GE): Manufactures LEAP engine nozzles with hybrid 3D printing, reducing jet engine size and weight.

Made in Space: Developed the Vulcan hybrid 3D printer under a NASA contract and is working on the Archinaut, a robotic 3D printer for space construction.

These examples highlight how hybrid manufacturing is revolutionizing aerospace design and production.

Automotive

Custom parts and rapid prototyping

Hybrid manufacturing is a game-changer for the automotive industry, especially in rapid prototyping. You can quickly iterate designs by combining 3D printing for complex geometries with CNC machining for precise finishing. This integration streamlines the manufacturing process, allowing you to create custom parts efficiently. For example, Nissan’s Moss emphasizes that hybrid technology not only enhances design but also improves assembly processes. The automaker’s "X-in-1" approach consolidates components, reducing size and weight while improving performance.

Advancements in vehicle design and performance

Hybrid manufacturing contributes to innovative vehicle designs and improved performance. By merging additive and subtractive processes, you can create intricate and efficient parts. Nissan’s modular "X-in-1" approach reduces component size by 30%, cuts production costs, and enhances noise and vibration control. These advancements demonstrate how hybrid manufacturing optimizes the manufacturing process while delivering superior vehicle performance.

Robotics

High-precision components for robotics and automation

Robotics demands high-precision components, and hybrid manufacturing delivers. By integrating additive and subtractive processes, you can achieve exceptional surface quality and dimensional accuracy. This ensures that robotic components meet rigorous standards for performance and aesthetics. For example, hybrid manufacturing enhances material versatility, allowing you to create a wider range of components with tight tolerances. This capability is crucial for robotics and automation, where precision directly impacts functionality.

Multi-material parts for enhanced functionality

Hybrid manufacturing enables the production of multi-material parts, offering unprecedented design possibilities. You can fabricate complex parts faster and with fewer setups, thanks to the unified environment of hybrid platforms. These systems also allow you to fine-tune parts through high-precision machining, ensuring functional integrity and exceptional surface quality. By combining the strengths of 3D printing and CNC machining, you can avoid the limitations of each technology while maximizing their benefits.

Medical Devices

Custom implants and prosthetics with superior biocompatibility

Hybrid manufacturing is transforming the medical device industry by enabling the creation of custom implants and prosthetics with enhanced biocompatibility. You can combine different materials to optimize specific properties for various parts of a device. For example:

Use 3D printing to create a custom-fit implant tailored to a patient’s anatomy.

Refine the implant with CNC machining to achieve precise dimensions and smooth surfaces.

Enhance biocompatibility by integrating materials that promote cellular growth and reduce rejection risks.

This approach ensures that medical devices not only fit perfectly but also function effectively within the human body.

Additionally, hybrid manufacturing allows you to produce advanced prosthetics like the Ability Hand by Psyonic. This prosthetic combines 3D printing, injection molding, and CNC machining to lower costs while improving durability and functionality. By tailoring devices to individual needs, you can significantly enhance user experience and comfort.

Examples of hybrid manufacturing in medical applications

Hybrid manufacturing has revolutionized the production of medical devices. You can now create custom implants and surgical instruments that meet specific patient requirements. This technology also supports the development of biocompatible frameworks essential for regenerative medicine. For instance, implants designed with hybrid techniques can encourage cellular growth, making them ideal for applications like bone regeneration. These advancements highlight how hybrid manufacturing ensures precision, adaptability, and superior performance in medical applications.

Energy Sector

Turbine components with enhanced durability

Hybrid manufacturing plays a vital role in producing turbine components with improved durability. You can use this technology to apply protective coatings that extend the lifespan of parts exposed to extreme conditions. By combining additive and subtractive processes, you can also create components with gradient material properties. This enhances their ability to withstand thermal and mechanical stresses, ensuring reliable performance in demanding environments.

Applications in renewable energy systems

In renewable energy systems, hybrid manufacturing enables the development of advanced thermal management solutions. You can design components that improve heat exchange processes, boosting energy conversion efficiency. For example, hybrid techniques allow you to create parts with optimized material properties, reducing waste and enhancing sustainability. Additionally, protective coatings applied through hybrid methods ensure that critical components last longer, even in harsh conditions. These innovations demonstrate how hybrid manufacturing supports sustainable energy production and drives efficiency in renewable technologies.

The Future of Hybrid Manufacturing

Advancing Material Innovation

Potential for creating entirely new classes of materials

Hybrid manufacturing opens doors to creating materials with unique properties. By combining 3D printing and injection molding, you can work with a wider range of materials, including metals and ceramics. This versatility allows you to use the same material and process for both prototypes and finished products. It simplifies production and enhances design flexibility.

You can integrate diverse materials into a single part, tailoring properties to meet specific needs.

This approach supports the creation of parts optimized for performance, improving both functionality and cost efficiency.

Successful trials have shown how hybrid manufacturing adapts to various materials and applications, especially those requiring additional processing.

This ability to engineer parts with customized properties ensures that you can innovate in ways traditional methods cannot match.

Role of hybrid manufacturing in sustainable production

Hybrid manufacturing contributes significantly to sustainable practices. It combines additive and subtractive processes, enabling faster prototyping and reducing errors. This efficiency minimizes waste and optimizes production planning.

You can recycle materials and reduce emissions, lowering the environmental footprint of your operations.

Advanced technologies like AI and IoT further enhance efficiency, making manufacturing more sustainable.

Blockchain technology improves supply chain transparency, helping you make environmentally conscious decisions.

By adopting hybrid manufacturing, you not only innovate but also align with global sustainability goals.

Emerging Technologies

Integration with AI and machine learning for smarter manufacturing

The integration of AI and machine learning transforms hybrid manufacturing into a smarter process. These technologies analyze data in real time, helping you identify defects and optimize workflows. Machine learning algorithms predict potential issues, allowing you to address them before they occur.

For example, AI-powered systems can adjust machine settings automatically, ensuring consistent quality. This reduces downtime and enhances productivity. By leveraging these tools, you can achieve greater precision and efficiency in your manufacturing processes.

Future trends in hybrid manufacturing systems

The future of hybrid manufacturing lies in its ability to adapt and evolve. Emerging trends include the use of IoT for real-time monitoring and control. Smart sensors embedded in hybrid machines provide valuable insights, enabling you to improve performance and reduce waste.

Another trend is the development of more compact and versatile hybrid systems. These machines combine multiple functions, allowing you to produce complex parts in a single setup. As these technologies advance, you can expect hybrid manufacturing to become even more accessible and efficient, driving innovation across industries.

Combining additive manufacturing and CNC machining offers you unmatched advantages. This hybrid approach enhances design flexibility, reduces waste, and improves material properties. It empowers you to create innovative components with superior strength and functionality. The potential for material innovation is transformative, enabling you to push the boundaries of what’s possible in manufacturing. By adopting hybrid manufacturing, you can streamline workflows and stay ahead in your industry. Explore this integration to unlock new opportunities and redefine how you design and produce materials. The future of manufacturing is in your hands.

FAQ

What is hybrid manufacturing?

Hybrid manufacturing combines additive manufacturing (3D printing) and CNC machining in one process. It allows you to create complex parts with precision by leveraging the strengths of both technologies. This approach improves efficiency, reduces waste, and enhances material properties for innovative applications.

Can hybrid manufacturing work with all materials?

Hybrid manufacturing supports a wide range of materials, including metals, plastics, and composites. However, the compatibility depends on the specific machine and process. You should check the material requirements of your project and the capabilities of the hybrid system you plan to use.

How does hybrid manufacturing reduce waste?

Hybrid manufacturing minimizes waste by using additive processes to build near-net-shape parts and CNC machining to refine them. This combination ensures that only necessary material is removed during machining, reducing excess material usage and lowering production costs.

Is hybrid manufacturing cost-effective?

Yes, hybrid manufacturing can save costs by streamlining production workflows and reducing material waste. It eliminates the need for separate setups and tooling, which lowers operational expenses. Additionally, it accelerates prototyping and production, saving time and resources.

What industries benefit most from hybrid manufacturing?

Industries like aerospace, automotive, medical devices, and energy benefit significantly from hybrid manufacturing. You can use it to create lightweight components, custom implants, high-precision parts, and durable turbine components. Its versatility makes it valuable across various fields.

See Also

Delving Into CNC Machining For Accurate Metal Fabrication

Investigating CNC Machining Solutions For High-Quality Production

Streamlined CNC Machining Services For Superior Manufacturing Precision

CNC Technology In Manufacturing: Understanding Its Innovations And Uses

Grasping Material Specifications For CNC Precision Machining Processes

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com