How to Achieve Cost Efficiency in Aluminum Manufacturing with CNC

CNC machining offers a reliable way to cut costs in aluminum manufacturing. Its precision and automation reduce waste and labor expenses while speeding up production. For example, an aerospace company redesigned a complex aluminum component using Design for Manufacturing principles. This change reduced production costs by 25% and cut lead times by 15%. Aluminum’s machinability also lowers energy consumption and equipment wear, making it an ideal material for CNC machining. Additionally, its durability and corrosion resistance reduce long-term costs by minimizing replacements and repairs.

Key Takeaways

CNC machining saves money by cutting waste and labor costs. It also makes production faster.

Picking the right aluminum, like 6061-T6, can save money. This alloy is easy to work with and very useful.

Simple designs for CNC machining save time and money. They make complex parts easier to create.

Automation helps machines run all the time. This lowers labor costs and boosts productivity.

Recycling aluminum saves money and helps the environment. It supports green manufacturing.

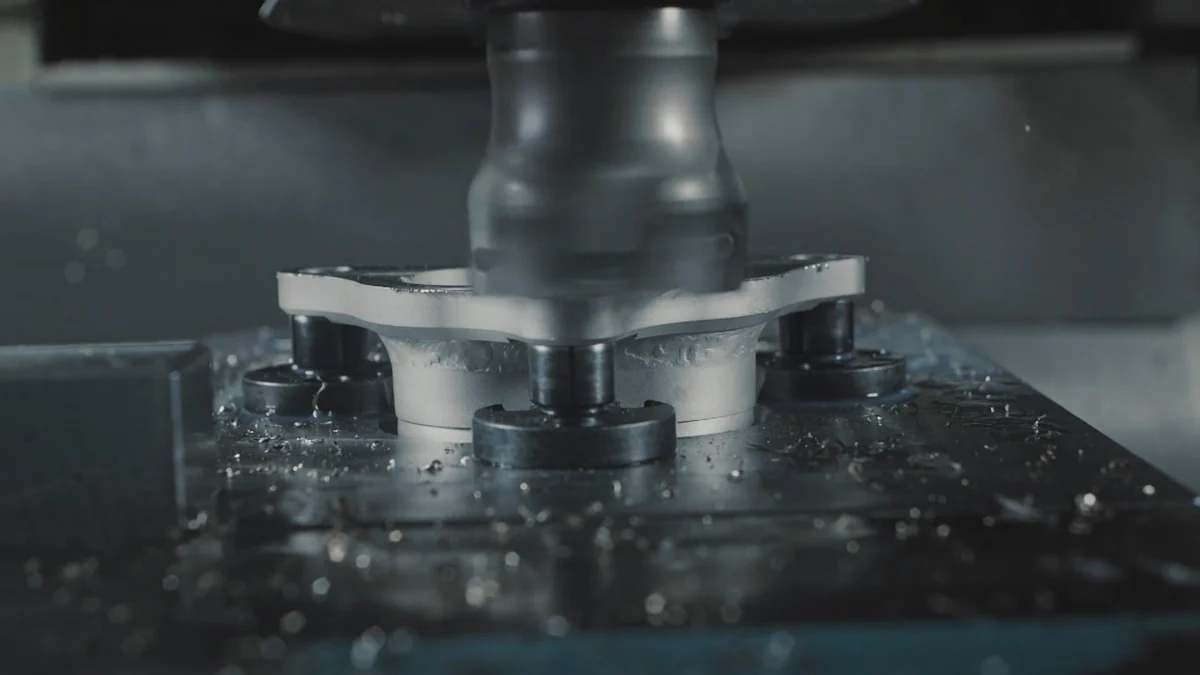

CNC Machining in Aluminum Manufacturing

Overview of CNC Machining

CNC machining is a process that uses computer-controlled tools to create precise and consistent parts. You start by designing a CAD model, which is then converted into a CNC program, often called G-code. This program guides the machine to cut, drill, or mill the material into the desired shape. For aluminum, the process involves selecting the right alloy, setting up tools, and calibrating the machine for accuracy. After machining, finishing processes like polishing or anodizing ensure the final product meets quality standards. This step-by-step approach minimizes errors and reduces the cost of cnc machining while maintaining high efficiency.

Why Aluminum is Ideal for CNC Machining

Aluminum offers several properties that make it perfect for CNC machining. It is lightweight yet strong, which is essential for industries like aerospace and automotive. Its excellent machinability allows you to create aluminum cnc parts quickly and accurately, reducing manufacturing costs. Aluminum also resists corrosion due to its protective oxide layer, making it suitable for harsh environments. Additionally, it is highly recyclable, which helps lower the cost of cnc machining aluminum and supports sustainable manufacturing practices.

Property | Description |

|---|---|

Good Machinability | Aluminum is easier to machine than many other metals, allowing for quick and accurate part creation. |

High Corrosion Resistance | Develops a protective oxide layer, making it resistant to corrosion and chemical damage. |

High Strength-to-Weight Ratio | Lightweight yet strong, enabling thicker and stronger parts while reducing overall weight. |

Recyclability | Highly recyclable, addressing material wastage concerns in CNC machining. |

Common Applications of Aluminum CNC Parts

Aluminum cnc parts are widely used across various industries due to their versatility and durability. In aerospace, you’ll find them in aircraft frames and turbine components, where lightweight strength is critical. Automotive manufacturers rely on aluminum for engine parts and chassis to improve fuel efficiency. Electronics companies use aluminum for device housings, combining protection with sleek aesthetics. Medical devices, such as surgical tools, also benefit from aluminum’s hygienic properties. Other applications include marine components, food processing machinery, and even sporting goods like bicycle frames. These examples highlight how aluminum cnc parts contribute to reducing manufacturing costs while ensuring quality and reliability.

Key Cost Factors in CNC Machining Aluminum

Material Selection and Costs

The type of aluminum you choose significantly impacts the cost of cnc machining aluminum. Common alloys like 6061-T6 are cost-effective due to their machinability and versatility. In contrast, high-performance alloys such as 7075-T6 are more expensive and harder to machine. For example, aluminum 6061 costs $25 per block, while 7075 costs $80 per block. These differences can influence your overall manufacturing costs. Additionally, fluctuations in market supply and demand can affect raw material costs, making it essential to monitor pricing trends.

Material waste also plays a role in determining costs. During machining, cutting waste increases the final material cost. However, aluminum’s recyclability helps reduce waste and offsets future expenses. By selecting the right alloy and optimizing material usage, you can lower the cost of cnc machining while maintaining quality.

Machine Type and Efficiency

The type of CNC machine you use directly affects machining costs and efficiency. Machines with advanced cooling systems prevent overheating, ensuring consistent performance. Precision controls improve accuracy, reducing errors and the need for rework. Features like automatic tool changers and adaptive feed rates enhance efficiency by minimizing downtime and optimizing machining for aluminum’s properties.

For aluminum cnc parts, machines with wide tooling compatibility and vacuum tables provide flexibility and stability. These features allow you to produce high-quality machined parts while keeping costs under control. Investing in efficient machines can help you reduce waste and improve overall manufacturing efficiency.

Feature | Description |

|---|---|

Advanced Cooling Systems | Prevent overheating during machining, ensuring consistent performance. |

Precision Controls | Improve accuracy and repeatability for consistent part production. |

Automatic Tool Changers | Minimize downtime by enabling quick tool changes. |

Adaptive Feed Rates | Adjust feed rates based on cutting load, enhancing efficiency with varying aluminum properties. |

Design Complexity and Machining Time

The complexity of your design has a direct impact on machining costs. Intricate geometries, fine dimensional requirements, and special features like deep hole machining require specialized tools and longer machining times. For example, parts requiring 4-axis or 5-axis machining take more time and increase costs. Simplifying designs and reducing the number of setups can lead to significant savings.

Complex designs also demand more process operations and different tools, which further raises machining costs. By optimizing your design for CNC machining, you can reduce machining time and lower the cost of cnc machining aluminum. This approach ensures you achieve high-quality aluminum cnc parts without unnecessary expenses.

Production Volume and Lead Times

Production volume and lead times play a critical role in determining the efficiency of CNC machining for aluminum. When you produce parts in large quantities, you can often achieve lower costs per unit. This happens because setup costs, such as machine calibration and tooling, are spread across a higher number of parts. For example, if you produce 1,000 aluminum CNC parts instead of 100, the cost per part decreases significantly.

Shorter lead times can also improve your manufacturing process. By reducing the time it takes to complete an order, you can meet customer demands faster and improve overall productivity. CNC machining excels in this area due to its automation and precision. Machines can run continuously with minimal supervision, allowing you to complete high-volume orders quickly.

Batch size impacts lead times as well. Small batches may require frequent machine setups, which increases downtime. On the other hand, larger batches reduce the need for repeated setups, saving time and resources. To optimize production, you should carefully plan batch sizes based on your order requirements and machine capacity.

Tip: Collaborate with your CNC machining provider to schedule production runs efficiently. This can help you balance lead times and production volume while keeping costs under control.

Additionally, consider the complexity of your parts. Simple designs take less time to machine, which shortens lead times. By simplifying your designs where possible, you can further enhance production efficiency and reduce delays.

Understanding how production volume and lead times affect your operations allows you to make informed decisions. This ensures you maintain a balance between cost, quality, and delivery speed.

Strategies to Reduce Costs in Aluminum Manufacturing

Optimizing Designs for CNC Machining

Optimizing your designs can significantly reduce cnc machining costs while maintaining quality. Simplify part designs to minimize machining time and costs. For example, reducing complex curved surfaces or unnecessary features can decrease machining time. Design parts closer to the raw material size to reduce waste. Using standardized components also eliminates the need for custom tooling, which simplifies manufacturing and lowers costs.

Selecting cost-effective materials is another way to reduce costs. Choose aluminum alloys that meet functional requirements without exceeding your budget. For instance, 6061-T6 is a versatile and affordable option for many applications. Additionally, applying cost-effective tolerances ensures functionality without unnecessary precision, which can increase machining costs. By implementing these strategies, you can achieve cost savings without compromising the quality of your aluminum cnc parts.

Efficient Toolpath Planning

Efficient toolpath planning plays a crucial role in reducing machining costs and improving toolpath efficiency. Aluminum’s machinability allows CNC machines to operate at higher speeds, which reduces production time and energy consumption. Optimizing toolpath strategies minimizes rapid movements and tool changes, leading to shorter cycle times and less tool wear.

Using continuous and smooth toolpaths instead of segmented ones enhances machining efficiency. Consolidating features to require fewer tool changes also saves time and improves production flow. These practices not only reduce cnc machining costs but also ensure consistent quality in your machined parts. By focusing on toolpath efficiency, you can streamline aluminum machining processes and achieve significant cost savings.

Minimizing Material Waste

Reducing material waste is essential for lowering manufacturing costs in aluminum machining. Design parts with hollow sections or closer to the raw material size to minimize waste. Recycling aluminum scraps is another effective strategy. Aluminum’s recyclability allows you to reuse leftover material, reducing raw material costs and environmental impact.

Lean manufacturing principles can also help reduce waste by aligning production with demand. This prevents overproduction and unnecessary material usage. Additionally, reusing coolants minimizes hazardous waste and reduces energy consumption. By adopting these practices, you can reduce waste, lower machining costs, and improve the sustainability of your aluminum manufacturing processes.

Leveraging Automation to Lower Labor Costs

Automation in CNC machining offers a powerful way to reduce labor expenses while maintaining high production efficiency. By integrating automated systems, you can minimize the need for manual intervention during the machining process. Machines equipped with robotic arms or automated loaders can handle tasks like material loading, unloading, and tool changes. This reduces the reliance on human operators and lowers overall labor costs.

Automated CNC machines also allow for continuous operation. Unlike human workers, machines can run 24/7 without breaks. This increases productivity and ensures that you meet tight deadlines without hiring additional staff. For example, a single operator can oversee multiple machines simultaneously, further reducing labor requirements.

Advanced software systems enhance automation by streamlining workflows. Features like real-time monitoring and predictive maintenance help you identify potential issues before they cause downtime. This reduces the need for frequent manual inspections and repairs. Additionally, automated quality control systems ensure consistent part accuracy, eliminating the need for rework and saving both time and money.

Automation also improves workplace safety. By reducing the need for manual handling of materials and tools, you can lower the risk of workplace injuries. This not only protects your workforce but also reduces costs associated with accidents and insurance claims.

Investing in automation may seem expensive initially, but the long-term savings outweigh the upfront cost. You’ll benefit from reduced labor expenses, faster production cycles, and improved product quality. By leveraging automation, you can achieve a more efficient and cost-effective aluminum manufacturing process.

Benefits of CNC Machining for Aluminum Manufacturing

Precision and Consistency in Aluminum CNC Parts

CNC machining ensures exceptional precision and consistency when creating aluminum parts. The computer-controlled process eliminates human error, delivering highly accurate results. For example, precision cutting achieves exact dimensions on both thin and thick aluminum plates. This level of accuracy is essential for industries like aerospace and medical manufacturing, where even minor deviations can compromise quality.

The process also prevents material deformation. Aluminum retains its original properties without warping or stress, even during intricate machining. Additionally, CNC machining improves surface finishes by minimizing tool marks. This reduces the need for post-processing, saving time and cost. Stress-free machining further ensures delicate or thin-walled components remain intact.

Benefit | Description |

|---|---|

Precision Cutting | Achieves extremely accurate cuts on both thin and thick aluminum plates, essential for high precision. |

No Material Deformation | Prevents warping or changes in aluminum, maintaining consistent material properties. |

Improved Surface Finish | Minimizes tool marks, providing a smoother finish and reducing the need for post-processing. |

Stress-Free Machining | Eliminates residual stresses or heat damage, crucial for delicate or thin-walled components. |

Faster Production and Reduced Costs

CNC machining aluminum enables faster production times while reducing costs. Aluminum’s machinability allows CNC machines to operate at high speeds, which shortens production cycles. Turning processes, for instance, are cost-effective due to their speed, reducing machine time expenses. The efficiency of CNC machines also minimizes energy consumption and wear on equipment, further lowering costs.

The process removes only the necessary material, reducing waste and enhancing cost efficiency. Precision machining minimizes defects, eliminating the need for costly rework. Additionally, CNC machining supports intricate designs that manual methods cannot achieve. This capability expands production possibilities while maintaining consistent quality across all parts.

High-speed operation reduces production times.

Efficient machines lower energy consumption and equipment wear.

Precision minimizes defects, reducing rework expenses.

Intricate designs enhance production capabilities.

Lower Labor Costs Through Automation

Automation in CNC machining significantly reduces labor costs. Automated systems handle tasks like material loading, unloading, and tool changes. This reduces the need for manual intervention, allowing a single operator to oversee multiple machines. Machines can also run continuously, increasing productivity without additional labor.

Advanced software streamlines workflows, enabling real-time monitoring and predictive maintenance. These features reduce downtime and the need for frequent inspections. Automated quality control ensures consistent part accuracy, eliminating rework and saving costs. By leveraging automation, you can achieve efficient aluminum manufacturing with lower labor expenses and higher output.

Sustainability and Recyclability of Aluminum

Aluminum stands out as one of the most sustainable materials you can use in manufacturing. Its recyclability not only reduces waste but also lowers production costs. When you recycle aluminum, it retains its original properties, allowing you to reuse it repeatedly without compromising quality. This makes it an excellent choice for eco-friendly manufacturing processes.

Recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. This significant energy savings reduces greenhouse gas emissions, helping you minimize your carbon footprint. For example, recycling one ton of aluminum saves approximately 14,000 kWh of energy and prevents 10 tons of CO₂ emissions. By incorporating recycled aluminum into your production, you contribute to a more sustainable future while cutting costs.

Did You Know? ♻️

Aluminum is one of the most recycled materials in the world, with a global recycling rate of over 75%.

Using recycled aluminum also helps you manage material waste more effectively. During CNC machining, leftover aluminum scraps can be collected and sent for recycling. This reduces the need for raw material purchases and aligns your operations with lean manufacturing principles. Additionally, recycling programs can generate revenue by selling scrap aluminum to recycling facilities.

Benefit | Description |

|---|---|

Energy Efficiency | Recycling aluminum uses 95% less energy compared to producing new aluminum. |

Waste Reduction | Recycled aluminum minimizes material waste during manufacturing. |

Cost Savings | Lower energy and raw material costs reduce overall production expenses. |

Environmental Impact | Recycling reduces greenhouse gas emissions and conserves natural resources. |

By prioritizing aluminum’s recyclability, you can achieve both economic and environmental benefits. This approach not only enhances your manufacturing efficiency but also supports global sustainability efforts.

CNC machining provides a practical path to cost efficiency in aluminum manufacturing. You can achieve savings by designing parts to use standard material sizes, optimizing tool paths, and standardizing processes. Larger production runs also reduce the cost per part by spreading setup expenses. Automation further enhances efficiency, allowing machines to operate continuously with minimal oversight. By adopting these strategies, you can streamline production, minimize waste, and maintain high-quality output. Explore CNC machining solutions to unlock these advantages and elevate your aluminum manufacturing processes.

FAQ

What is the most cost-effective aluminum alloy for CNC machining?

6061-T6 is the most cost-effective alloy. It offers excellent machinability, strength, and corrosion resistance. You can use it for a wide range of applications without exceeding your budget. Its versatility makes it a popular choice for reducing manufacturing costs.

How can you reduce material waste during CNC machining?

Design parts closer to the raw material size to minimize waste. Use hollow sections where possible. Recycle leftover aluminum scraps to save costs and reduce environmental impact. These strategies help you optimize material usage and improve sustainability.

Does automation in CNC machining require a large investment?

Automation requires an upfront investment, but it reduces labor costs and increases productivity over time. Machines can run continuously with minimal supervision. This long-term efficiency offsets the initial expense, making automation a cost-effective solution for aluminum manufacturing.

Why is aluminum considered sustainable for manufacturing?

Aluminum is highly recyclable. Recycling uses 95% less energy compared to producing new aluminum. It retains its properties after recycling, reducing waste and conserving resources. By using recycled aluminum, you lower costs and contribute to environmental sustainability.

Can CNC machining handle complex aluminum part designs?

Yes, CNC machining excels at creating complex designs. It uses advanced tools and multi-axis machines to achieve intricate geometries. You can produce high-precision parts with consistent quality, even for challenging designs, without compromising efficiency or accuracy.

See Also

Streamlined CNC Machining Solutions for Accurate Production

Benefits of Utilizing Aluminum CNC Machining Services

Impact of CNC Precision Parts on Production Expenses

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com