Strategies for Cost-Efficient Material Procurement in CNC Services

Cost-efficient material procurement plays a critical role in CNC machining. Material costs can significantly impact profitability, especially when rare materials or complex designs are involved. For instance, plastics are more affordable than metals like titanium, but machinability and availability also influence expenses. You face challenges like managing tooling costs, optimizing machine operation time, and ensuring effective supplier communication. Ignoring these factors can lead to delays and higher costs. By adopting cost-saving strategies, such as bulk purchasing or design optimization, you can reduce CNC machining costs while maintaining quality and efficiency.

Key Takeaways

Material prices greatly impact CNC machining profits. Pick materials carefully to save money.

Buying in large amounts can get discounts and cut costs. Plan purchases well to save more.

Simple part designs use less time and waste less material. Keep only important features for better results.

Good supplier connections can mean lower prices and steady quality. Talk clearly to make good deals.

Tools like software can cut waste and boost efficiency. Use data to make smarter choices.

Factors Influencing Material Costs in CNC Machining

Material Availability and Sourcing

Material availability plays a significant role in determining the cost of CNC machining projects. When materials are scarce, their prices increase, directly impacting your budget. Rare materials, such as titanium or high-grade tool steel, often come with higher costs due to limited supply. Even common materials like aluminum or stainless steel can vary in price depending on their grade and global demand.

You should also consider how sourcing affects costs. Locally sourced materials may reduce shipping expenses and lead times, while international suppliers might offer lower base prices but add logistical challenges. Commonly used materials in CNC machining include aluminum 6061, stainless steel 304, and ABS plastic. Each material has unique properties and availability, so selecting the right one for your project can help you manage costs effectively.

Tip: Collaborate with suppliers to understand material availability and secure the best pricing for your needs.

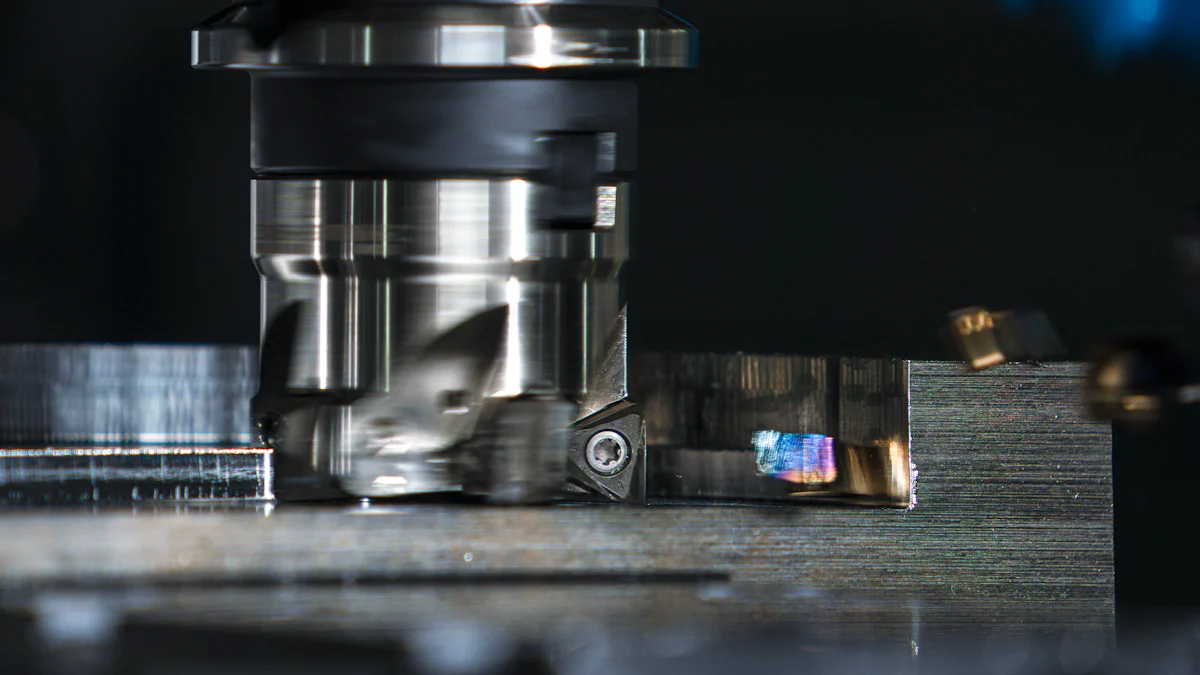

Machinability and Its Impact on Costs

The machinability of a material directly influences CNC machining costs. Materials like aluminum and certain plastics are easier to machine, reducing production time and tool wear. This efficiency lowers labor and operational expenses. On the other hand, harder materials, such as hardened steel or composites, require specialized tools and longer machining times, increasing costs.

Several factors determine machinability, including hardness, strength, and thermal conductivity. For example, materials with high thermal conductivity, like copper, disperse heat effectively, reducing the risk of overheating during machining. By choosing materials with better machinability, you can optimize production and minimize costs.

Note: While machinable materials save time and money, ensure they meet your project’s strength and durability requirements.

Bulk Purchasing and Order Volume

Bulk material purchasing offers significant cost-saving opportunities in CNC machining. Ordering materials in larger quantities often results in discounts and lower per-unit costs. For example, suppliers may offer price breaks when you negotiate long-term contracts or purchase in bulk. This approach also ensures a steady supply of materials, reducing the risk of production delays.

Order volume impacts supplier pricing as well. High-volume orders allow you to spread fixed setup costs over more units, reducing the overall cost per part. Conversely, low-volume or one-off orders incur higher costs due to custom tooling and programming.

Production Volume | Cost Implications |

|---|---|

High Volume | Lower per-unit cost due to economies of scale. |

Medium Volume | Moderate per-unit cost with some savings. |

Low Volume | Higher per-unit cost due to fixed expenses. |

Prototype/One-Off | Very high per-unit cost with custom setups. |

Tip: Use an accurate bill of materials (BOM) to plan bulk purchases and avoid overstocking.

Cost-Saving Strategies for Material Selection

Exploring Material Alternatives

Choosing the right material can significantly reduce cnc machining costs. You should explore cost-effective material options that balance price, machinability, and performance. For example, aluminum 6061 offers high machinability and corrosion resistance, making it a popular choice for cost-effective cnc machined parts. Plastics like ABS and POM (Delrin) provide moderate machinability and are suitable for lightweight applications.

Material | Cost Effectiveness | Machinability |

|---|---|---|

Aluminum 6061 | High | Very Good |

ABS | Moderate | Moderate |

Nylon | Moderate | Moderate |

POM (Delrin) | Moderate | Moderate |

PEEK | Low | Difficult |

When selecting materials, consider machining costs and lifecycle costs. Materials like aluminum and ABS reduce machining time and tool wear, lowering cnc machining costs. However, durable materials like stainless steel or PEEK may justify higher initial costs due to their longevity.

Tip: Evaluate your project’s requirements to find the best balance between cost and performance.

Collaborating with Suppliers for Better Pricing

Building strong relationships with suppliers can help you reduce cnc machining costs. Collaboration fosters trust and transparency, enabling you to negotiate better pricing. Engage in joint business planning sessions to align your needs with supplier capabilities. Use data-driven insights to evaluate supplier performance and identify cost-saving opportunities.

Suppliers often offer customized solutions tailored to your project’s needs. Long-term partnerships also ensure consistent quality and supply chain stability. For example, suppliers familiar with your specifications can streamline production and reduce lead times.

Note: Transparent communication during negotiations strengthens relationships and ensures mutual benefits.

Leveraging Bulk Purchasing Discounts

Bulk purchasing is a proven strategy to reduce cnc machining costs. Ordering materials in larger quantities often results in volume discounts and lower per-unit costs. Analyze historical spend data to identify patterns and forecast future needs. This approach helps you plan bulk orders effectively and avoid overstocking.

Key Steps | Description |

|---|---|

Historical spend analysis | Review past procurement data to identify overspending and savings opportunities. |

Future spend forecasting | Predict future needs to optimize budgeting and negotiations. |

Automated cost analysis | Use technology to monitor costs and identify discrepancies in real time. |

A strong vendor network also plays a crucial role. Reliable suppliers can quickly provide materials at competitive prices, ensuring uninterrupted production.

Tip: Use an accurate bill of materials (BOM) to plan bulk purchases and maximize savings.

Design Optimization to Reduce CNC Machining Costs

Reducing Material Waste

Reducing material waste is one of the most effective ways to lower cnc machining costs. CNC machines already excel at precision, which minimizes excess material during production. However, you can take additional steps to further optimise design and minimise material wastage.

Simplify part designs to reduce unnecessary machining steps.

Use standardized components to avoid custom tooling.

Select cost-effective materials that balance functionality and price.

Implement efficient tooling strategies, such as optimizing tool paths and using multipurpose tools.

Specify necessary tolerances to avoid over-engineering parts.

Advanced CAD and CAM software also play a crucial role. These tools optimize material usage by simulating machining processes, ensuring minimal scrap. In industries where materials like titanium or PEEK are used, reducing waste can significantly lower production costs. Less waste also means fewer disposal and recycling expenses, contributing to overall savings.

Tip: Design parts with machinability in mind to minimize waste and machining time.

Simplifying Part Designs

Simplifying part designs is another key strategy to optimise design and reduce costs. Complex features should only be included when absolutely necessary for functionality. By designing parts that require minimal repositioning, you can save time and reduce labor costs.

Avoid intricate geometries that demand advanced machinery.

Split complex parts into simpler sections for easier machining.

Reduce the number of machining steps by eliminating unnecessary features.

Simplified designs also minimise material wastage and machining time. For example, fewer tool changes and streamlined processes enhance production efficiency. This approach not only lowers cnc machining costs but also ensures faster turnaround times.

Note: Specify necessary tolerances to control costs without compromising part quality.

Prototyping for Material Efficiency

Prototyping is essential for achieving material efficiency in cnc machining. It allows you to test and refine designs before full-scale production, minimizing waste and errors. CNC machines provide high precision, ensuring prototypes meet tight tolerances.

Benefit | Description |

|---|---|

Design Optimization | Prototyping enables design adjustments to reduce waste. |

Material Waste Reduction | Identifies unnecessary material usage, leading to savings. |

Cost Efficiency | Small batch production prevents costly defects. |

Enhanced Accuracy | Ensures prototypes meet specifications closely. |

Superior Repeatability | Guarantees consistent features for final products. |

Excellent Material Compatibility | Supports various materials, optimizing selection for efficiency. |

Prototyping also helps you select the right material for your project. Materials like aluminum, known for their machinability, allow for simpler designs and quicker processing times. This reduces machining time and labor costs, making prototyping a cost-effective step in the production process.

Tip: Use prototyping to refine designs and minimise material wastage before mass production.

Supplier Relationship Management for Cost Efficiency

Evaluating and Comparing Suppliers

Choosing the right supplier is crucial for managing cnc machining costs effectively. You should evaluate suppliers based on several criteria to ensure they meet your project’s requirements.

Thermal Properties: Check if the material can withstand the required temperature range.

Surface Finish: Determine if the supplier can deliver the desired texture or smoothness.

Mechanical Properties: Assess the material’s strength, hardness, and durability.

Cost: Compare pricing to find the most cost-effective option.

Environmental Factors: Ensure the material suits the operating environment.

Regularly reviewing supplier relationships can uncover cost-saving opportunities. Effective communication with suppliers helps you identify these opportunities and avoid disruptions. Miscommunication often leads to delays, higher costs, and poor material choices. By maintaining open communication, you can streamline your supply chain and enhance cost efficiency.

Negotiating Long-Term Contracts

Long-term vendor contracts offer multiple benefits for cnc machining projects. Suppliers can anticipate your needs and streamline their processes, ensuring seamless synchronization. These contracts often lead to favorable pricing and discounts, reducing overall cnc machining costs.

Suppliers familiar with your requirements can provide customized solutions and maintain consistent quality. Long-term relationships also foster innovation, as suppliers contribute to improving your designs and processes. Open communication channels make problem-solving faster and more effective.

Additionally, long-term contracts stabilize your supply chain. You reduce reliance on ad-hoc suppliers, minimizing risks of delays or shortages. Suppliers motivated by long-term partnerships are more likely to address issues promptly and align with your company’s values.

Exploring Local and International Suppliers

Sourcing materials locally or internationally impacts your costs and timelines. Local suppliers often offer faster delivery, sometimes within a day, while international shipments may take 6-8 weeks. Transportation costs increase with distance, and tariffs can further affect international sourcing expenses.

Local suppliers provide better quality control and compliance with standards. However, international suppliers might offer lower base prices, which could offset shipping and tariff costs in some cases. Balancing these factors is essential to optimize your cnc machining costs.

When exploring suppliers, consider building a diverse network. A mix of local and international vendors ensures flexibility and cost efficiency. This approach helps you adapt to changing market conditions while maintaining a steady supply of materials.

Leveraging Technology for Cost-Saving Strategies

Material Optimization Software

Material optimization software helps you reduce waste and improve efficiency in cnc machining. These tools analyze your designs and suggest ways to minimize material usage without compromising functionality. For example, they can identify areas where thinner walls or smaller dimensions are feasible. This reduces the amount of raw material required for production.

Such software also allows you to simulate machining processes. By doing so, you can predict potential issues and adjust designs before production begins. This proactive approach saves time and prevents costly errors. Additionally, material optimization software supports a wide range of materials, enabling you to explore cost-effective alternatives.

Tip: Use material optimization software to refine your designs and achieve maximum material efficiency.

Real-Time Monitoring Systems

Real-time monitoring systems provide valuable insights into your cnc machining operations. These systems track machine performance, detect inefficiencies, and reduce downtime. Within the first month of implementation, they can lower downtime by up to 25%. This translates to a savings of 1.25 hours in mass production and up to 3 hours in batch production.

With enhanced monitoring, you can identify the main causes of downtime and take corrective actions. Improved overall equipment effectiveness (OEE) boosts production without requiring additional machines. This reduces operational costs and increases profitability.

Benefits of real-time monitoring systems:

Reduced downtime and increased productivity.

Identification of inefficiencies for targeted improvements.

Enhanced OEE, leading to cost savings.

Note: Real-time monitoring systems help you optimize production and reduce unnecessary expenses.

Data-Driven Procurement Decisions

Data-driven procurement decisions allow you to make informed choices about materials and suppliers. By analyzing production patterns and trends, you can identify areas for improvement and develop cost-saving strategies. For instance, data analytics can reveal which materials offer the best balance of cost and performance for your cnc machining projects.

This approach also helps you forecast future needs accurately. With better predictions, you can plan bulk purchases and negotiate favorable terms with suppliers. Data-driven decisions ensure that your procurement process aligns with your production goals, reducing waste and improving efficiency.

Tip: Leverage data analytics to optimize your procurement strategy and achieve long-term savings.

Reducing cnc machining costs requires a strategic approach. You can achieve this by optimizing material selection, simplifying designs, and leveraging technology. Building strong supplier relationships and using bulk purchasing also help reduce cnc machining costs effectively.

Balancing cost, quality, and efficiency ensures your projects remain competitive. By implementing these strategies, you not only reduce cnc machining costs but also improve profitability. Start applying these methods today to secure long-term success in cnc machining operations.

FAQ

What is the most cost-effective material for CNC machining?

Aluminum 6061 is one of the most cost-effective materials. It offers excellent machinability, durability, and corrosion resistance. For lightweight applications, ABS plastic is another affordable option. Your choice depends on your project’s requirements for strength, weight, and performance.

How can you reduce material waste during CNC machining?

You can reduce waste by simplifying part designs, using efficient tool paths, and selecting materials with high machinability. Advanced CAD/CAM software also helps optimize designs and minimize scrap. Focus on precision and avoid over-engineering parts to save material.

Should you always buy materials in bulk?

Bulk purchasing is cost-effective for high-volume production. However, for small projects or prototypes, buying only what you need prevents overstocking. Use an accurate bill of materials (BOM) to plan purchases and avoid unnecessary expenses.

How do supplier relationships impact CNC machining costs?

Strong supplier relationships lead to better pricing, consistent quality, and reliable delivery. Collaborating with suppliers helps you negotiate discounts, secure long-term contracts, and streamline your supply chain. This reduces costs and ensures smooth operations.

Can technology help lower CNC machining costs?

Yes, technology like material optimization software and real-time monitoring systems reduces waste and improves efficiency. These tools analyze designs, track machine performance, and provide data-driven insights. Using them helps you make smarter decisions and cut costs effectively.

See Also

Streamlined CNC Machining Solutions For Accurate Production

Impact Of CNC Precision Parts Processing On Production Expenses

Grasping Material Needs For CNC Precision Machining

Investigating CNC Machining Options For Precise Manufacturing

Key Elements Influencing CNC Precision Parts Processing Costs

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com