How Custom CNC Services Are Ideal for Prototype Development and Small-Batch Production

When you're working on prototype development or small-batch production, precision and speed matter. Custom CNC services excel here. They offer rapid prototyping, unmatched accuracy, and cost-effective solutions. Industries like medical and aerospace rely on CNC machining for its ability to handle complex prototype design while ensuring consistent quality and faster time-to-market.

Key Takeaways

Custom CNC services offer great accuracy and fast results. They are perfect for making prototypes and small amounts of products.

CNC machining removes the need for costly molds. This lowers expenses and helps make design changes quickly.

CNC machines can work with many materials. This ensures prototypes match the needed functions.

Understanding Custom CNC Machining

What Are Custom CNC Services?

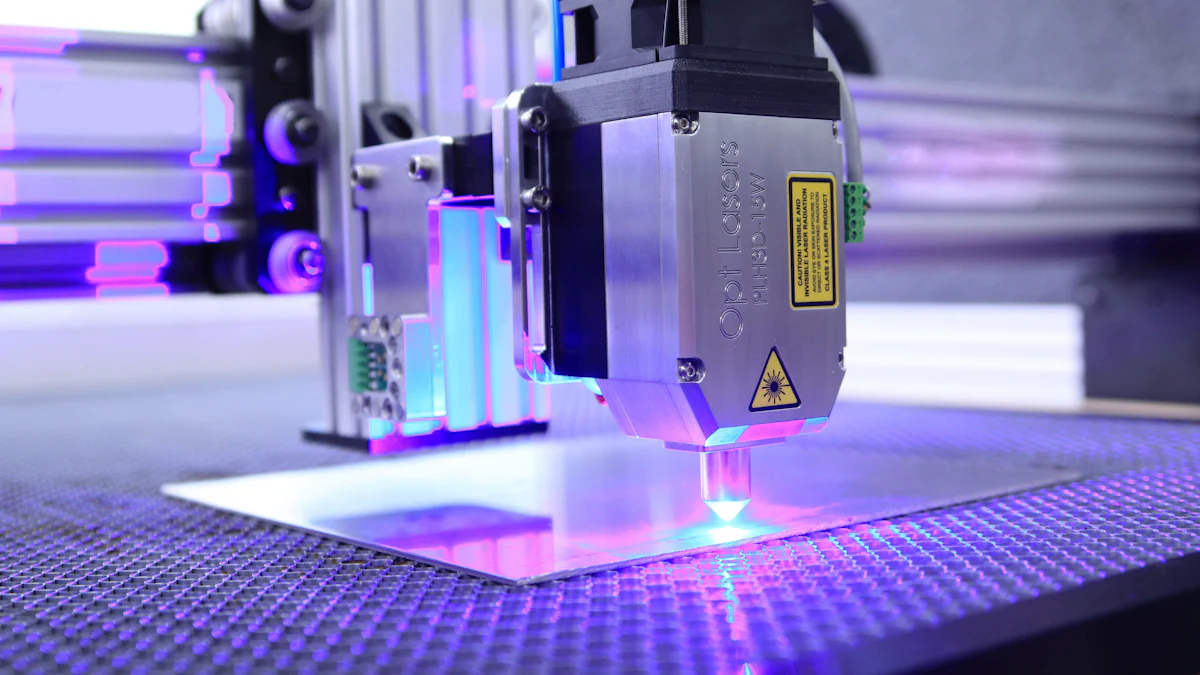

Custom CNC services involve the use of computer-controlled machines to create precise and complex parts tailored to your specific needs. These services utilize various machining techniques, such as CNC milling, turning, and laser cutting, to produce high-quality components. Whether you're working on a prototype design or small batch CNC machining, these services offer unmatched precision and repeatability. Unlike traditional methods, custom CNC machining allows for rapid prototyping and quick adjustments, making it ideal for industries like aerospace, robotics, and automotive.

Custom CNC machining stands out because it can handle a wide range of materials, including metals, plastics, and composites. This versatility ensures that you can create parts that meet your exact specifications, whether for product testing or final production. Plus, the process eliminates the need for time-consuming mold creation, saving you both time and money.

Key Features of Custom CNC Machining

Custom CNC machining is packed with features that make it a go-to solution for small batch CNC machining and prototype design. Here are some of the standout features:

Accurate Tool Path Control: Ensures the cutting tool follows the exact programmed path, delivering high precision.

Stable Machine Structure: Reduces vibrations, resulting in consistent and reliable machining outcomes.

Advanced Measurement Systems: Real-time sensors make adjustments during machining, enhancing both precision and efficiency.

Automation: Features like automatic tool changers and pallet changers reduce downtime, boosting productivity.

Flexibility and Customization: Programmable operations allow you to switch between different designs quickly, making it perfect for rapid prototyping.

These features enable CNC machining production to achieve tolerances as tight as 0.001 inches, ensuring that every part meets your exact requirements.

Benefits Over Standard CNC Machining

When comparing custom CNC machining to standard methods, the differences are clear. Here's a quick breakdown:

Feature | Custom CNC Machining | Traditional CNC Machining |

|---|---|---|

Precision and Consistency | Offers unparalleled precision and consistency | Depends on operator skill, may vary |

Complexity and Versatility | Can produce complex shapes and designs | Limited by operator capability |

Speed and Efficiency | Reduces production time significantly | Slower due to manual operations |

Labor and Skill Level | Requires programming knowledge | Demands highly skilled operators |

Cost and Investment | Higher initial investment, long-term savings | Cheaper to start, higher long-term costs |

Flexibility and Adaptation | Ideal for custom and variable production | Better for single-type, long-run projects |

Custom CNC machining also excels in creating stronger, more precise parts compared to alternatives like molding or 3D printing. This makes it a preferred choice for industries requiring high-quality components, such as semiconductors, robotics, and optical communication.

Advantages of CNC Machining for Prototypes and Small-Batch Production

Precision and Accuracy for Prototypes

When you're developing a prototype, precision is everything. CNC machining ensures high accuracy by using computerized controls to guide cutting tools. This process achieves tight tolerances, often as precise as 0.001 inches. You can trust that your prototype will meet exact specifications without needing multiple iterations.

CNC machining provides consistent results, reducing errors caused by manual processes.

The tight tolerances ensure your prototype functions as intended, saving time and costs.

Errors in prototypes are usually linked to design flaws, not machining inaccuracies.

Industries like medical, automotive, and aerospace rely on CNC machining for prototypes that demand extreme precision. For example, surgical tools, automotive gears, and aerospace components like airfoils require tight tolerances. CNC machining delivers the accuracy needed for these critical applications.

Cost-Effectiveness for Low-Volume Production

CNC machining is a cost-efficient choice for small-batch CNC machining. It eliminates the need for expensive molds or tooling, making it perfect for low-volume production. By simplifying part designs and using standardized components, you can further reduce costs.

Producing parts in batches spreads fixed costs over multiple units, lowering the cost per part.

Streamlining machining processes minimizes production time and expenses.

Selecting cost-effective materials aligns with your budget while meeting functional needs.

A table of cost-saving strategies:

Strategy | Description |

|---|---|

Simplifying designs | Reducing unnecessary complexities and focusing on manufacturability can effectively lower costs. |

Optimizing processes | Streamlining the number of processes through design optimization can help reduce costs. |

Utilizing standardized components | Incorporating standardized components can significantly reduce costs due to economies of scale. |

Adopting lean manufacturing | Continuous improvement and lean practices focus on waste elimination and efficiency enhancement. |

Effective tooling and material selection | Specifying only essential tolerances and finishes can control costs. |

Batch production also leverages economies of scale, making CNC machining production an affordable option for small-batch projects.

Material Versatility and Design Flexibility

CNC machining offers unmatched material versatility, allowing you to create prototypes from metals, plastics, and composites. This flexibility ensures your prototype meets specific mechanical properties and functional requirements.

Common materials include aluminum, stainless steel, titanium, ABS, and polycarbonate.

Multi-axis machining supports intricate designs and complex geometries.

Rapid prototyping is possible, enabling quick iterations and adjustments.

For example, you can use lightweight aluminum for aerospace parts or durable stainless steel for medical devices. The ability to switch between materials and designs makes CNC machining ideal for iterative refinement of the product. Whether you're testing a new concept or finalizing a design, CNC machining adapts to your needs with ease.

Comparing CNC Machining to Other Manufacturing Methods

CNC Machining vs. 3D Printing

When deciding between CNC machining and 3D printing, you need to consider precision, material options, and production needs. CNC machining offers unmatched precision, achieving tolerances as tight as 0.005 mm, compared to 3D printing's typical 0.2 mm. This makes CNC machining ideal for applications requiring high accuracy, like aerospace or medical components.

Material versatility is another area where CNC machining shines. While 3D printing is limited to specific materials like plastics and a few metals, CNC machining supports a wide variety, including aluminum, titanium, and composites. This flexibility allows you to choose materials that meet your exact requirements for strength, durability, or heat resistance.

Here’s a quick comparison:

Attribute | 3D Printing | CNC Machining |

|---|---|---|

Precision | Typically around 0.2 mm | 0.005 mm precision |

Material Availability | Limited | Wide variety available |

For small-batch CNC machining, CNC machining production offers greater flexibility and cost efficiency. You can quickly adjust designs, customize parts, and achieve faster time-to-market. This makes it a better choice for low-volume production and product testing.

CNC Machining vs. Injection Molding

CNC machining and injection molding both have their strengths, but CNC machining is better suited for small-batch CNC machining and prototype development. Injection molding requires expensive molds, making it cost-prohibitive for low-volume production. CNC machining eliminates this hurdle, offering lower upfront costs and faster lead times.

CNC machining typically delivers parts within 1-2 weeks, while injection molding can take 2-6 weeks due to mold creation.

It provides design flexibility, allowing you to make quick changes without the need for new molds.

CNC machining supports a wide range of materials, from metals to flexible plastics, ensuring your parts meet specific functional needs.

Injection molding also struggles with producing complex geometries and tight tolerances. CNC machining overcomes these limitations, delivering high precision and customization. Whether you’re creating prototypes or small-batch CNC machined parts manufacturing, CNC machining production ensures faster turnaround and cost efficiency.

Tip: If you need rapid iterations or customized designs, CNC machining services are your best bet.

Custom CNC machining stands out as the perfect choice for prototype development and small-batch production. Why?

It ensures precision and repeatability, producing high-quality prototypes.

You save time and money by skipping expensive tooling.

Rapid iterations keep your project on track.

Its versatility supports diverse materials and designs.

Industry | Application |

|---|---|

Automotive | Precision parts enhance functionality and reliability. |

Aerospace | Custom components meet strict industry standards. |

Medical | High-quality devices ensure patient safety and care. |

Electronics | Intricate parts meet diverse requirements. |

Construction | Durable components adapt to demanding applications. |

Explore CNC machining to bring your ideas to life with speed and accuracy.

FAQ

What industries benefit the most from small-batch production using CNC machining?

Industries like aerospace, medical, and automotive benefit greatly. CNC machining ensures precision, flexibility, and cost-efficiency, making it ideal for small-batch production and prototype development.

How does CNC machining reduce costs for small-batch production?

CNC machining eliminates the need for expensive molds and tooling. It allows you to produce parts quickly and efficiently, saving time and money in small-batch production.

Can CNC machining handle complex designs for small-batch production?

Absolutely! CNC machining excels at creating intricate designs and tight tolerances. It’s perfect for small-batch production where precision and customization are essential.

See Also

Streamlined CNC Machining Solutions For Accurate Production Needs

Investigating CNC Machining Options For Precision Engineering

Addressing Issues: Improving CNC Prototyping Precision And Speed

How Small Parts CNC Influences Custom R/C Hobby Creations

Tailored CNC Milling Solutions: Perfecting Precision Engineering Methods

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com