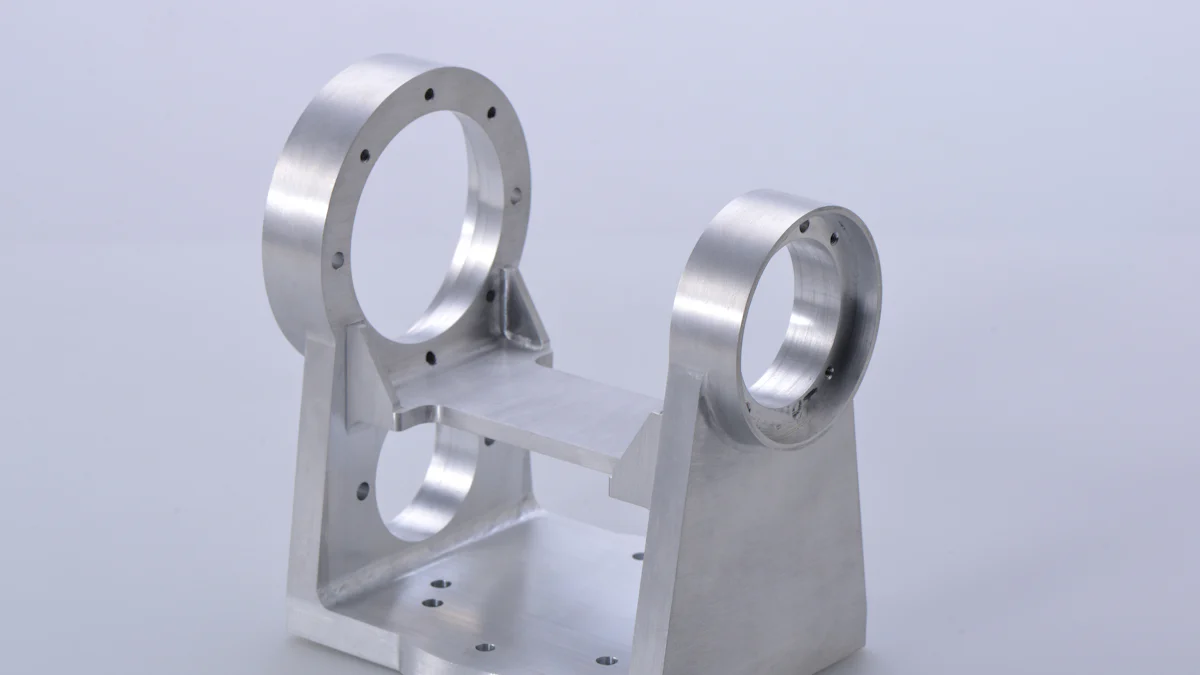

Design Optimization for Manufacturability in CNC Machining CNC Hardware Parts Design

In the realm of modern manufacturing, CNC machining stands as a pivotal force driving precision and efficiency. The quest for optimal design is paramount, resonating deeply in the world of CNC hardware parts design. Embracing design optimization for manufacturability is not merely a choice but a strategic imperative. It intertwines cost-effectiveness with quality, sculpting the very essence of successful production endeavors.

Key Design Considerations

Material Selection

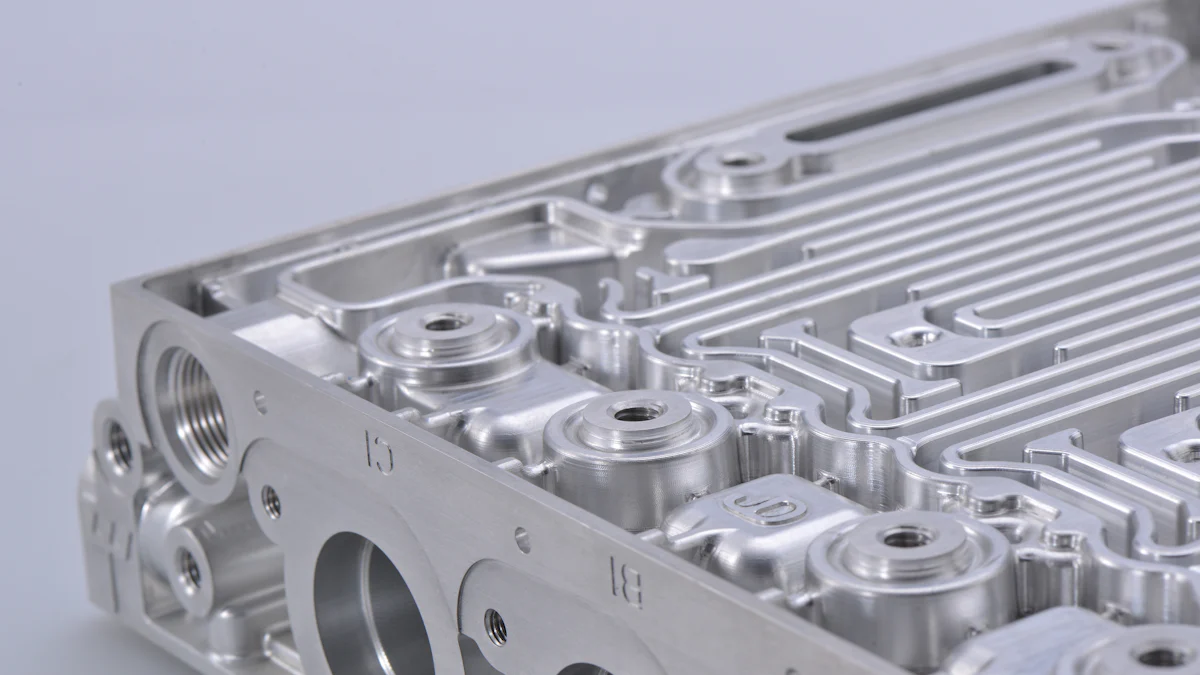

Aluminum, known for its thermal resistance and high strength, is a prevalent choice in CNC machining CNC hardware parts design. Aluminum 6061-T6, a versatile alloy, offers corrosion resistance and machinability. Plastics like acrylic, despite potential cracking issues, are favored for their adaptability in creating precise components. Various CNC metals such as stainless steel and titanium provide properties like corrosion resistance and high heat deflection.

Common materials used in CNC machining

Aluminum: Offers hardness and electrical conductivity.

Plastics: Known for adaptability despite drawbacks like thermal softening.

CNC Metals: Provide high corrosion resistance and impact resistance.

Factors influencing material choice

Properties: Consider thermal resistance and machinability.

Application: Evaluate the material's suitability for the part's function.

Cost-effectiveness: Balance quality with production costs.

Impact of material properties on manufacturability

Material selection affects machinability and part durability.

Optimal material properties enhance the efficiency of the manufacturing process.

Geometric Features

Designing geometric features plays a pivotal role in ensuring the manufacturability of CNC hardware parts. Understanding key aspects such as hole depth, wall thickness, and tolerances is essential for creating functional components that meet quality standards.

Hole depth and diameter

Maintain consistency in hole dimensions to facilitate machining processes.

Consider the depth-to-diameter ratio to ensure structural integrity.

Wall thickness and its implications

Opt for appropriate wall thickness to prevent deformations during machining.

Thicker walls enhance part stability while maintaining design integrity.

Tolerances and their impact on part quality

Precision Requirements: Define tolerances based on functional needs.

Quality Assurance: Ensure tolerances align with manufacturing capabilities.

Dimensional Accuracy: Control tolerances to achieve desired part dimensions.

Design Complexity

Simplifying complex designs is crucial for streamlining the manufacturing process of CNC hardware parts. By focusing on functionality while considering manufacturability aspects, designers can optimize their creations effectively using CAD software tools.

Simplifying complex designs

Break down intricate features into simpler elements for ease of production.

Minimize unnecessary complexities that may hinder manufacturing efficiency.

Balancing functionality and manufacturability

Functional Design Elements: Prioritize features that enhance part performance.

Manufacturing Feasibility: Ensure designs are feasible within production constraints.

Using CAD software for design optimization

Leverage CAD software capabilities to visualize designs before production.

Conduct simulations to identify potential manufacturing challenges early in the design phase.

Strategies for Cost Reduction

Efficient toolpath planning is a cornerstone of cost reduction in CNC machining CNC hardware parts design. By minimizing tool changes, manufacturers streamline the production process, enhancing efficiency and reducing downtime. Optimizing cutting parameters further refines the machining operation, ensuring precise and swift material removal.

Batch Production Techniques

The utilization of batch production techniques offers a myriad of benefits in the realm of manufacturing. Designing for multiple parts per setup maximizes productivity by capitalizing on shared resources and reduced setup times. This approach not only enhances operational efficiency but also drives down overall production costs.

Improving Part Quality

Surface Finish Considerations

Achieving the desired surface finish is a critical aspect of enhancing the quality of CNC hardware parts. The surface finish not only impacts the aesthetics but also influences the functionality and performance of the final product.

Techniques for achieving desired surface finish

Utilize appropriate cutting tools to achieve specific surface finishes.

Implement proper machining strategies to enhance surface smoothness.

Consider post-processing methods such as polishing or coating for refined finishes.

Impact of cutting tools on surface quality

American Micro Industries emphasizes the importance of selecting the right cutting tools to ensure optimal surface quality. Different tools can significantly affect the final finish, so choosing wisely is key to achieving superior results.

Post-processing methods

Explore various post-processing techniques like sanding or deburring to improve surface texture.

Anodizing or plating can be employed to enhance both aesthetics and durability.

Incorporate shot peening or vibratory finishing for unique textures and improved part performance.

Inspection and Testing

Quality control measures are indispensable in ensuring that CNC hardware parts meet stringent standards for functionality and reliability. Integrating inspection and testing processes into the design phase enhances overall part quality.

Importance of quality control

According to 3ERP, meticulous quality control procedures are fundamental in verifying part accuracy and consistency. Rigorous inspections guarantee that each component meets specified requirements, fostering trust in the final product's performance.

Common inspection techniques

Conduct dimensional inspections using precision measuring tools like calipers or micrometers.

Employ visual inspections to detect imperfections or irregularities on part surfaces.

Perform material testing through hardness tests or spectroscopy analysis for material integrity assessment.

Integrating testing into the design process

Incorporate testing checkpoints at key design stages to identify potential issues early on.

Collaborate with quality assurance teams to establish robust testing protocols aligned with design specifications.

Continuously refine testing procedures based on feedback from manufacturing processes for ongoing quality improvement.

In the realm of CNC hardware parts design, optimizing for manufacturability is a strategic imperative. By embracing design optimization principles, designers can enhance part quality while reducing production costs. Understanding the impact of material selection and geometric features is crucial in achieving efficient CNC machining processes. Finalizing designs with cost-effective strategies and a focus on part quality ensures successful manufacturing endeavors. For further insights into CNC hardware parts design, exploring additional resources can broaden knowledge horizons.

See Also

Perfecting CNC Machining for Accurate Parts Production

Mastery of CNC Machining: Precision, Prototyping, and Materials

Grasping Material Needs for CNC Precision Machining

Impact of CNC Precision Parts Processing on Manufacturing Expenses

Essentials of CNC Machining for Producing Components and Parts

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com