Exploring CNC Milling: A Comprehensive Overview of Precision Engineering

CNC Milling Overview

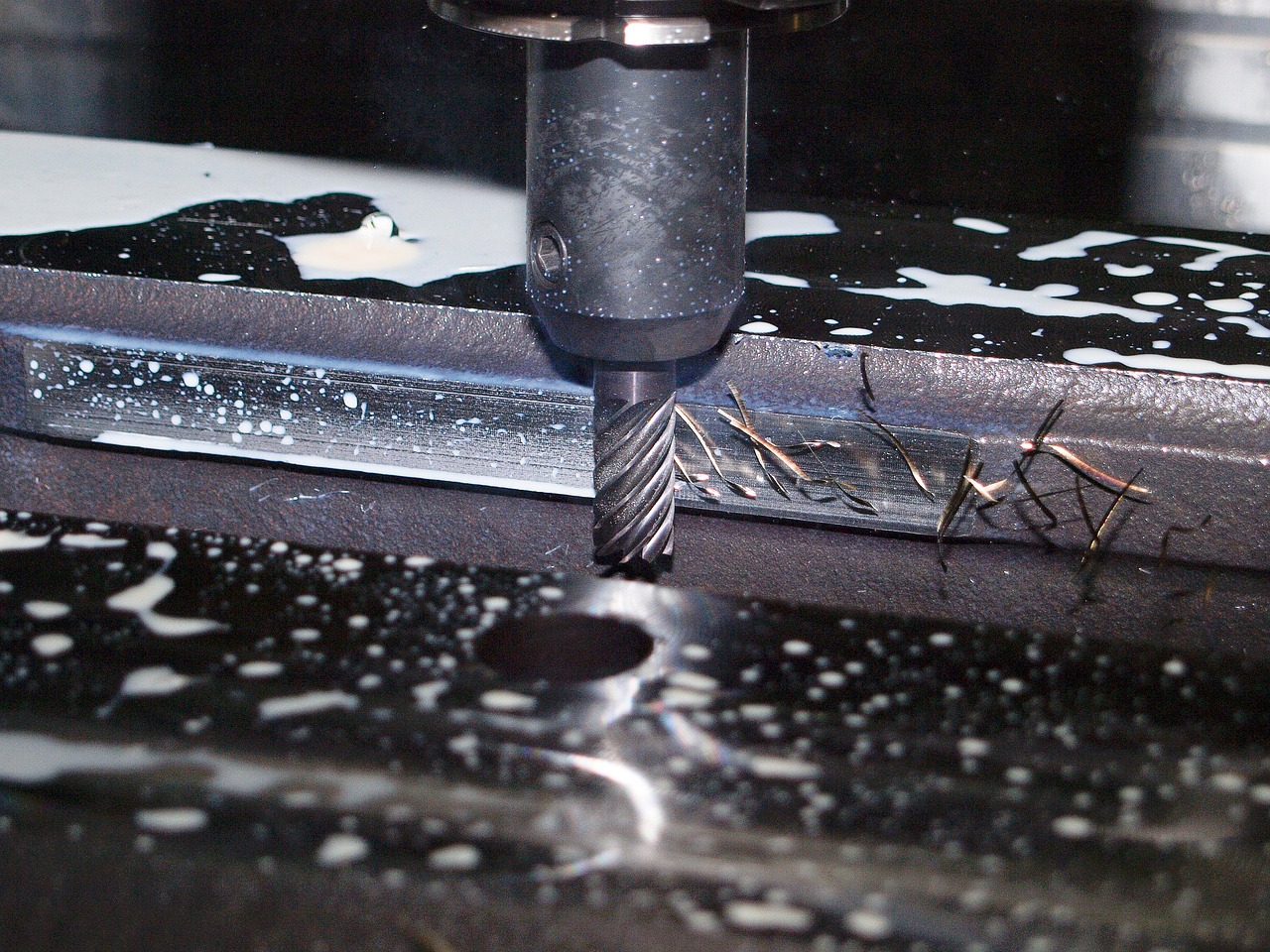

CNC milling, also known as computer numerical control milling, is a fundamental process within the realm of precision engineering. It involves the use of computer-controlled machinery to meticulously remove material from a workpiece, resulting in the creation of highly accurate and intricate components. This technology plays a pivotal role in various industries, offering unparalleled precision and efficiency in manufacturing processes. CNC milling has revolutionized the production of complex parts, driving advancements in automation and technological innovation.

Technology Evolution

Historical Development

The inception of CNC milling dates back to the 1940s, where it was initially developed for manufacturing purposes. This marked a significant advancement in precision engineering, allowing for the automated shaping of materials with unprecedented accuracy.

Over time, CNC milling technology has undergone substantial evolution, integrating advanced computer systems to enhance precision and automation in machining processes.

Modern Innovations

In contemporary times, CNC milling has redefined manufacturing by offering unparalleled precision and efficiency. The seamless integration of cutting-edge software and hardware has propelled CNC milling to new heights of technological innovation, enabling the creation of highly intricate components with remarkable accuracy.

"The advancements in CNC milling have transformed the way we approach manufacturing, allowing for the production of complex parts with minimal human intervention," stated John Smith, a leading expert in precision engineering.

John Smith: "The advancements in CNC milling have transformed the way we approach manufacturing, allowing for the production of complex parts with minimal human intervention."

Advantages and Applications

CNC milling offers a multitude of operational benefits and diverse applications within the field of precision engineering and manufacturing.

Operational Benefits

The technology of CNC milling brings forth enhanced accuracy, consistency, and repeatability in manufacturing processes. This results in the production of components with precise specifications, meeting the highest quality standards.

With minimal human intervention required, CNC milling enables the production of complex and intricate components. This not only enhances efficiency but also reduces the margin for error, ensuring reliable and consistent output.

Diverse Applications

The versatility of CNC milling makes it indispensable in various industries such as aerospace, automotive, and medical device manufacturing. Its ability to produce intricate parts with high precision is particularly valuable in these sectors where safety and reliability are paramount.

Moreover, CNC milling allows for the creation of a wide range of components and products, from engine parts for aircraft to custom medical implants. Its adaptability across different industries underscores its significance in modern manufacturing processes.

Precision engineering, manufacturing, and technology have all been seamlessly integrated into the operational benefits and diverse applications of CNC milling.

Machine Operations

Process Overview

In the realm of precision engineering and manufacturing, CNC milling operates through a meticulously orchestrated process. It entails the utilization of computerized instructions to precisely control the movement of cutting tools. This process encompasses several distinct stages, beginning with the design phase where the specifications for the component are translated into digital instructions. Subsequently, programming involves the creation of a set of commands that guide the machinery in executing precise movements. Following this, setup procedures are carried out to prepare the CNC milling machine for operation, ensuring that all components are aligned and calibrated accurately. Finally, the machining stage involves the actual material removal process, where the workpiece is sculpted according to the programmed specifications.

Safety Measures

Adhering to stringent safety protocols is imperative in CNC milling operations to safeguard against potential accidents and ensure the well-being of operators. Proper training plays a pivotal role in equipping personnel with the necessary skills to operate CNC milling machinery safely and efficiently. Additionally, regular equipment maintenance is essential to uphold operational safety standards and prevent unforeseen malfunctions that could compromise operator safety. By prioritizing safety measures and adherence to established protocols, CNC milling operations can maintain a secure working environment while optimizing production efficiency.

machining and automation play crucial roles in both the process overview and safety measures within CNC milling operations.

Environmental Impact

CNC milling has a significant impact on environmental sustainability due to its precise material removal, minimizing material wastage and promoting eco-friendly manufacturing practices. This aligns with global efforts towards environmental conservation and sustainable production processes.

Efforts to optimize energy usage in CNC milling contribute to reduced environmental impact and operational costs. By implementing energy-efficient strategies, the technology enhances its overall sustainability while reducing its carbon footprint. These initiatives not only benefit the environment but also contribute to cost savings for manufacturers, making CNC milling an environmentally conscious choice for precision engineering and manufacturing processes.

CNC Milling Summary

CNC milling has truly revolutionized precision engineering, offering unparalleled automation and accuracy in manufacturing processes. The impact of this technology extends across diverse industries, driving innovation and efficiency. With its ability to produce intricate components with minimal human intervention, CNC milling has become an indispensable tool in modern manufacturing. From aerospace to medical device manufacturing, the versatility of CNC milling underscores its significance in creating highly precise and complex parts. As the industry continues to evolve, CNC milling remains at the forefront of precision engineering, shaping the future of manufacturing.

See Also

A Beginner's Comprehensive Guide to CNC Technology

Precision Machining and CNC Services: Tianjie CNC's Impact on Industries