The Future of CNC Milling: Advancements and Versatile Applications

Evolving CNC Technology

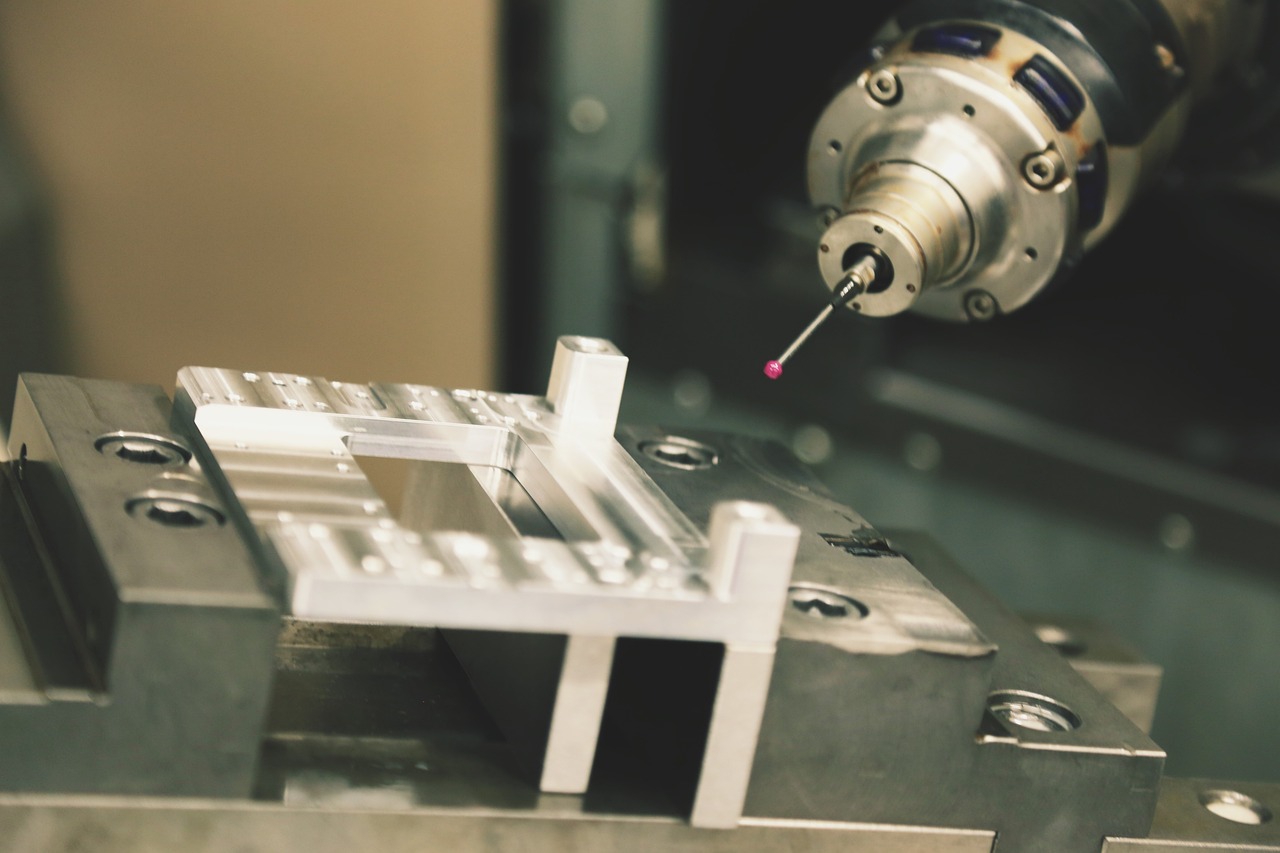

CNC milling, also known as computer numerical control milling, has completely transformed the landscape of manufacturing processes. This advanced milling technology has automated and streamlined production, leading to increased precision and efficiency. The integration of CNC technology has significantly enhanced the capabilities of traditional milling processes, allowing for more intricate and complex designs to be realized with unparalleled accuracy.

The evolution of CNC milling technology has paved the way for versatile applications across various industries, from aerospace and automotive manufacturing to medical device production and beyond. As this technology continues to advance, it is poised to further revolutionize the way products are designed and manufactured.

Precision Milling

High Precision Output

CNC milling ensures precise and accurate output, meeting the exact specifications required for various manufacturing needs.

The technology enables the creation of intricate and complex designs with unparalleled precision, allowing for the production of highly detailed components.

Versatility in Material Milling

CNC milling demonstrates versatility in working with a wide range of materials, including metals, plastics, and composites.

From aluminum and steel to ABS and acrylics, the technology offers diverse milling options to accommodate different material requirements.

Diverse Milling Applications

Industrial Applications

CNC milling plays a pivotal role in industrial manufacturing, offering a wide array of applications across various sectors. The technology provides cost-effective solutions for mass production, allowing industries to efficiently produce high-quality components and products at scale. This efficiency not only reduces production costs but also enhances the overall manufacturing process.

Industry Expert: "CNC milling has significantly optimized industrial manufacturing processes, enabling precise and rapid production of complex parts and components."

Environmental Benefits

In addition to its industrial applications, CNC milling contributes significantly to environmental sustainability. By reducing material waste and energy consumption, this advanced technology minimizes the environmental impact of manufacturing processes. Furthermore, the precision of CNC milling results in minimal material wastage, aligning with sustainable manufacturing practices and reducing the overall carbon footprint.

Future of CNC Technology

Advancements in CNC Milling

As CNC technology continues to progress, the future of CNC milling holds exciting possibilities for further advancements. These advancements are anticipated to propel the capabilities of milling technology to new heights, leading to even more precise and efficient manufacturing processes.

One area of potential development lies in the enhancement of software integration with CNC milling machines. Advanced software solutions are expected to optimize toolpath generation, enabling smoother and more efficient machining operations. This improvement can significantly contribute to minimizing production time while maintaining exceptional precision.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms is poised to revolutionize CNC milling processes. AI-powered systems have the potential to analyze and adapt machining strategies in real-time, resulting in adaptive toolpaths that maximize efficiency without compromising accuracy.

Industry Analyst: "The incorporation of AI into CNC milling technology represents a significant leap forward, promising adaptive and responsive machining capabilities that can revolutionize manufacturing efficiency."

Another area of focus for advancements in CNC milling involves the exploration of innovative cutting tools and materials. Research and development efforts are directed towards creating cutting-edge tooling solutions that enhance material removal rates while ensuring superior surface finishes. Additionally, the utilization of advanced composite materials for cutting tools aims to extend tool life and improve overall machining performance.

Role in Various Industries

CNC milling plays a pivotal role across diverse industries, ranging from automotive and aerospace to medical device manufacturing and beyond. As manufacturing technology continues to advance, CNC milling is expected to remain at the forefront, shaping the future of production processes across various sectors.

The unparalleled precision and versatility offered by CNC milling technology make it an indispensable asset in industries where complex components demand high levels of accuracy. From intricate aerospace components to intricately designed medical implants, CNC milling ensures that manufacturers can consistently deliver top-quality products with exacting specifications.

In addition, as industries increasingly emphasize sustainable practices, CNC milling's ability to minimize material waste aligns with environmental conservation efforts. By reducing energy consumption and optimizing material usage, this advanced technology contributes significantly to sustainable manufacturing practices across diverse industrial domains.

The future role of CNC milling in various industries is not only about enhancing production efficiency but also about driving innovation through advanced machining capabilities that enable the realization of previously unattainable designs and product features.

The Promising Future of CNC Milling

As CNC milling continues to advance, its promising future is poised to make a lasting impact across various industries. The evolution of this technology has already revolutionized manufacturing processes, leading to increased precision and efficiency. With further advancements on the horizon, CNC milling is set to continue shaping the way products are designed and manufactured, offering unparalleled capabilities in precision milling and versatile applications.

Industry Expert: "The future of CNC milling holds exciting possibilities for further advancements that can propel manufacturing processes to new heights."

The integration of AI and machine learning algorithms is anticipated to revolutionize CNC milling processes by enabling adaptive toolpaths that maximize efficiency without compromising accuracy.

Ongoing research and development efforts are focused on innovative cutting tools and materials aimed at enhancing material removal rates while ensuring superior surface finishes.

CNC milling's role in various industries, from aerospace to medical device manufacturing, is expected to remain pivotal as it drives innovation through advanced machining capabilities. With its ability to minimize material waste and align with sustainable practices, CNC milling stands as an indispensable asset in shaping the future of production processes.

See Also

Uncovering CNC Milling: A Thorough Look at Precision Engineering

Tianjie CNC: Improving Industries through Precision Machining and CNC Solutions

Discovering the Benefits of Aluminum CNC Machining Solutions

Newcomer's Guide to CNC Turning: Precision Machining Simplified