The Future of Manufacturing: Why CNC Automatic Machines Are Key to Success

CNC Machining has revolutionized manufacturing by delivering unmatched precision and efficiency. These CNC Machining machines can execute cuts with tolerances as tight as 0.001 inches, ensuring consistent quality. Their ability to operate continuously with minimal human intervention reduces errors and boosts productivity. With the global CNC Machining market projected to grow from $67.5 billion in 2023 to $80.4 billion by 2028, their adoption is essential for staying competitive.

Key Takeaways

CNC machines are very accurate and work quickly, making more products faster.

Using CNC machines cuts down mistakes and waste, keeping quality steady and saving money.

CNC machines make workplaces safer, keeping workers safe and boosting work speed.

The Evolution of CNC Machining

From Manual Processes to CNC Automation

The journey from manual machining to CNC automation has transformed the manufacturing landscape. Early machining processes relied heavily on skilled labor, which often led to inconsistencies and slower production times. The 1940s marked a turning point when John T. Parsons introduced the concept of numerical control, laying the foundation for CNC technology. By 1952, MIT demonstrated the first numerical control machine, showcasing its ability to follow coded instructions. This innovation replaced manual operations with automated precision, revolutionizing machining forever.

The 1960s and 1970s saw the integration of computers into machining, enabling faster and more accurate operations. By the 1980s, microprocessors and digital technologies further enhanced CNC machines, transitioning them from hard-wired systems to software-based applications. Today, CNC machining interprets CAD files to create complex designs with unmatched precision and efficiency. This evolution has not only improved productivity but also set new standards for quality and consistency in manufacturing.

Global Adoption and Cost-Effectiveness

CNC automation has gained global traction due to its cost-effectiveness and ability to enhance efficiency. Unlike traditional methods, CNC machines operate continuously without breaks, significantly reducing labor costs. They also minimize material waste, which is crucial for managing production expenses. Manufacturers benefit from rapid prototyping capabilities, allowing faster production cycles and reduced costs.

Additionally, CNC machining reduces errors to nearly zero, ensuring consistent quality and minimizing waste. This reliability makes it a preferred choice for industries worldwide. By automating routine tasks, CNC technology allows you to allocate human resources more efficiently, addressing labor shortages and improving overall productivity.

The Role of CNC in Modern Manufacturing

CNC machining plays a pivotal role in addressing modern manufacturing challenges. Its ability to operate autonomously ensures stable production even during labor shortages. The precision of CNC machines allows you to produce high-quality parts consistently, meeting the growing demand for customization.

Moreover, CNC automation integrates seamlessly with Industry 4.0 technologies, providing real-time insights and enhancing connectivity. This adaptability helps manufacturers stay competitive in a rapidly changing market. By reducing reliance on manual labor and improving efficiency, CNC machining has become indispensable in modern manufacturing.

Key Benefits of CNC Automation

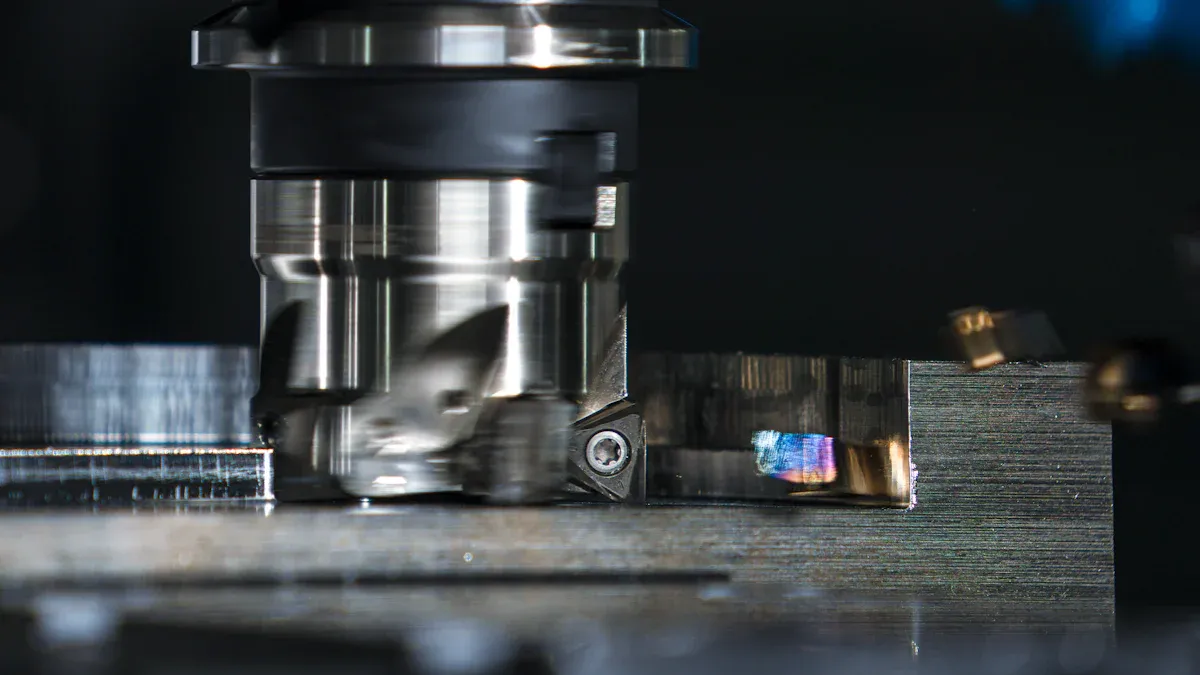

Speed and Precision in Manufacturing

CNC machining delivers unmatched speed and precision, making it a cornerstone of modern manufacturing. You can achieve faster production cycles and higher output compared to manual methods. For example, CNC machines reduce setup time from 30 minutes to just 5 minutes and cycle time per part from 30 minutes to 5 minutes. This efficiency allows you to produce up to 96 parts daily, compared to only 16 parts with manual machining.

CNC automation also ensures error-free production. Every unit matches the design specifications exactly, eliminating the inconsistencies often seen in manual processes. Advanced technologies like multi-axis machining enable simultaneous operations, further boosting productivity. With the ability to run 24/7, CNC machines maximize production capacity while maintaining precision.

Consistency and Quality Control

Consistency is critical in modern manufacturing, and CNC machining excels in this area. You can rely on CNC machines to produce parts that meet exact dimensions and tolerances every time. Regular inspections during the machining process catch even minor deviations early, preventing costly product failures.

This level of quality control not only reduces waste but also ensures your products consistently meet or exceed customer expectations. By maintaining high standards, you build trust and foster long-term relationships with your clients. Early defect detection also minimizes financial losses, making CNC automation a cost-effective solution for mass production.

Versatility Across Materials and Industries

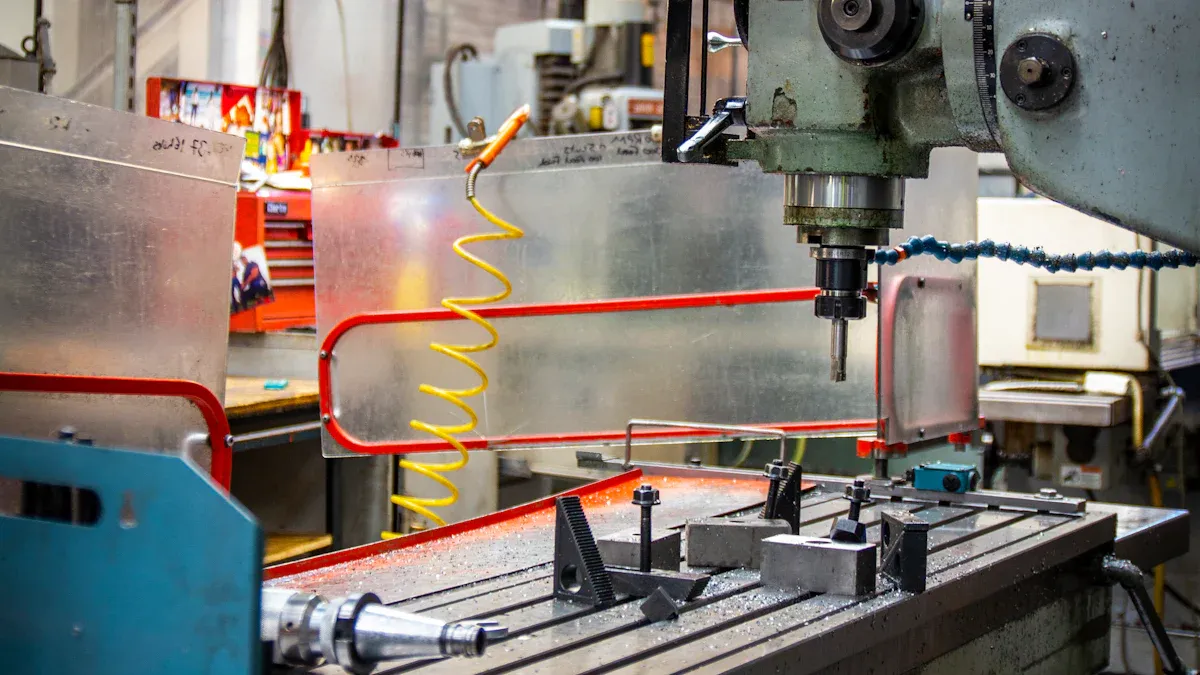

CNC machining stands out for its versatility, accommodating a wide range of materials and industries. Whether you work with plastics, metals, or carving foam, CNC machines adapt to your needs. For instance, plastics are ideal for medical applications like custom packaging, while carving foam benefits the marine industry due to its moisture resistance. Metals, commonly associated with CNC machining, allow for precision in various applications, from automotive to aerospace.

This adaptability makes CNC automation a valuable tool across industries. You can switch between materials seamlessly, enabling diverse production capabilities without compromising efficiency or quality.

Enhanced Safety and Reduced Errors

CNC machines prioritize operator safety through advanced technologies. Features like fixed guards, interlocking guards, and light curtains prevent access to hazardous parts, reducing workplace accidents. Safety contact mats and CNC machine safety glass provide additional layers of protection, ensuring a secure working environment.

You can also monitor operations remotely using video cameras, avoiding exposure to flying debris. Cooling fluids reduce heat and friction, enhancing both safety and machining performance. These safety measures not only protect workers but also minimize errors, ensuring smooth and efficient production processes.

The Future of CNC in Manufacturing

Hybrid Machines and Multi-Functional Systems

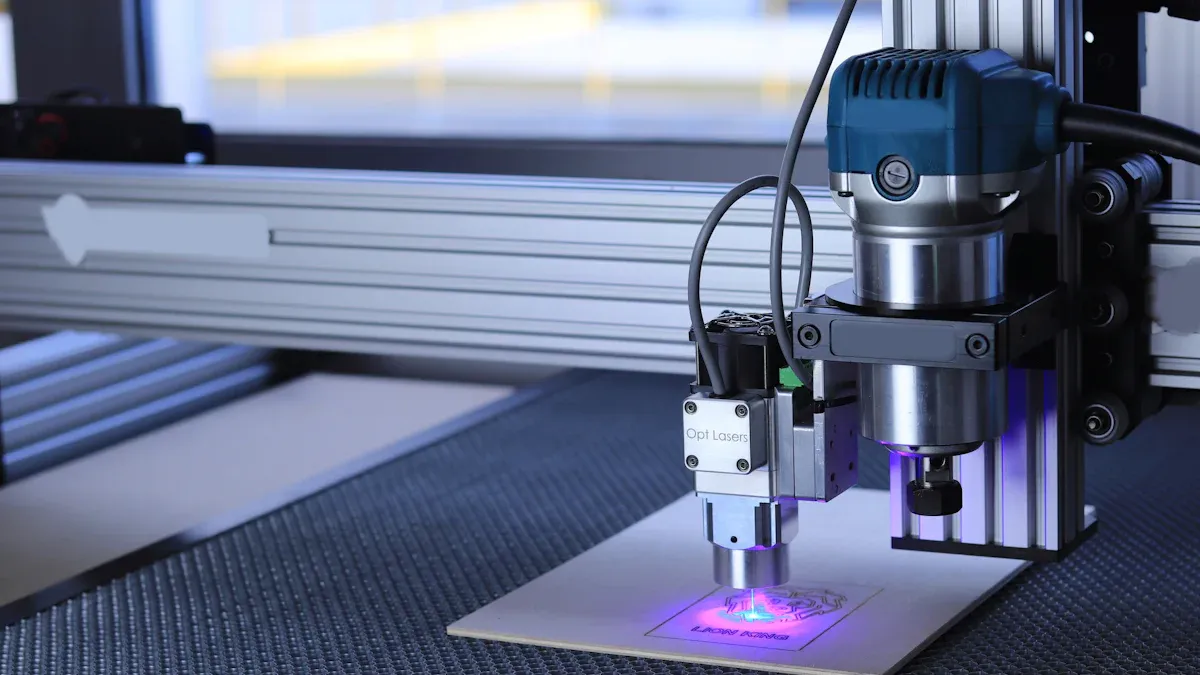

Hybrid CNC machines are transforming the manufacturing landscape by combining additive and subtractive processes. These multi-tasking systems allow you to switch seamlessly between operations, enhancing versatility and efficiency. With advancements in precision engineering, hybrid machines can achieve intricate details and tight tolerances, ensuring high-quality outputs.

Material innovation is another exciting development. New materials expand the capabilities of hybrid CNC systems, enabling superior component production. By integrating digital tools, these machines also support smarter production processes, aligning with the principles of industry 4.0. This combination of flexibility and precision positions hybrid CNC systems as a cornerstone of the future of machining.

Smart Manufacturing and Connectivity

Smart manufacturing leverages CNC automation alongside IoT and connectivity technologies to revolutionize production. Real-time data monitoring provides continuous feedback, enhancing operational accuracy and efficiency. Predictive maintenance forecasts machine failures, reducing downtime and ensuring smooth operations.

Remote operation capabilities allow you to manage CNC systems from distant locations, offering unparalleled flexibility. Enhanced data collection and analysis refine processes, improving product quality. By integrating CNC machining with industry 4.0 technologies, smart manufacturing reduces idle times, operational costs, and potential hazards, creating a safer and more efficient production environment.

Integration with Robotics and AI

The combination of CNC machining with automation and robotics is reshaping production lines. AI-driven robots enable smarter and faster operations, reducing downtime and increasing output. These technologies address challenges like labor shortages and rising production costs while meeting the growing demand for high-quality products.

Industrial automation improves consistency and safety in manufacturing processes. AI optimizes production by analyzing vast amounts of data, learning from it, and enhancing machine productivity. This integration of CNC systems with robotics and AI ensures precision, flexibility, and resilience, making it a vital component of the future of manufacturing.

Sustainability and Eco-Friendly Practices

CNC machining contributes significantly to sustainability in manufacturing. By optimizing material usage, it reduces waste and minimizes scrap. Energy-efficient machines lower operational costs and emissions, aligning with eco-friendly practices. High-quality outputs result in durable products, reducing the need for replacements and promoting sustainability.

The integration of industry 4.0 technologies further enhances efficiency by reducing energy consumption. Predictive maintenance and multi-axis computational machining minimize material waste and energy use. Advanced materials and recycled resources improve sustainability, while VR and AR technologies streamline design and training, reducing resource waste. CNC systems play a pivotal role in creating a greener future for manufacturing.

CNC automation has redefined manufacturing by delivering precision, efficiency, and consistency. You can rely on it to minimize errors, reduce waste, and improve safety. Its ability to produce high-quality parts with speed and accuracy ensures you stay ahead in a competitive market.

CNC technology enhances efficiency by improving part quality and consistency. Its precision and repeatability make it indispensable for the future of manufacturing.

Adopting CNC systems prepares your business for the demands of Industry 4.0. By investing in these technologies, you ensure long-term success and innovation in an evolving industry.

FAQ

1. What industries benefit the most from CNC automation?

CNC automation supports industries like aerospace, automotive, healthcare, and electronics. Its precision and versatility make it ideal for producing complex parts across diverse applications.

2. How does CNC machining reduce production costs?

CNC machining minimizes waste, reduces labor expenses, and ensures consistent quality. Its ability to operate continuously boosts efficiency, saving you time and money.

3. Can small businesses afford CNC machines?

Yes! Entry-level CNC machines offer cost-effective solutions for small businesses. They provide scalability and efficiency, helping you compete with larger manufacturers.

💡 Tip: Start with a basic CNC machine and upgrade as your business grows. This approach balances affordability and functionality.

See Also

Understanding CNC Machining's Benefits and Future Developments

CNC Technology's Role in Modern Manufacturing Innovations

CNC Technology: Its Journey and Future Innovations Ahead

Seven Essential Advantages of CNC Machining in Manufacturing

The Transformation of Precision Manufacturing Through CNC Technology

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com