How CNC Machines Revolutionized Manufacturing

CNC machines have transformed the manufacturing industry by introducing automated processes that enhance precision and productivity. Unlike traditional methods, these machines operate with unmatched efficiency, significantly reducing production time and labor costs. For instance, CNC machining automates tasks that once required manual adjustments, allowing operations to run 24/7. This revolutionizing technology plays a pivotal role in automating processes, enabling manufacturers to meet growing demands while minimizing waste.

The global CNC machine market reflects this shift. Valued at $79.69 billion in 2023, it is projected to reach $123.63 billion by 2032, driven by the need for cost-effective and efficient production. With their ability to streamline operations and deliver consistent results, CNC machines continue to redefine modern manufacturing.

Key Takeaways

CNC machines make manufacturing easier, more accurate, and faster.

They work nonstop, helping factories meet demands and cut waste.

CNC tools finish jobs 75 to 300% quicker than doing it by hand.

Adding AI and IoT makes these machines smarter and more efficient.

CNC machines save energy and reduce waste, helping the environment.

Understanding CNC Machines

What Are CNC Machines?

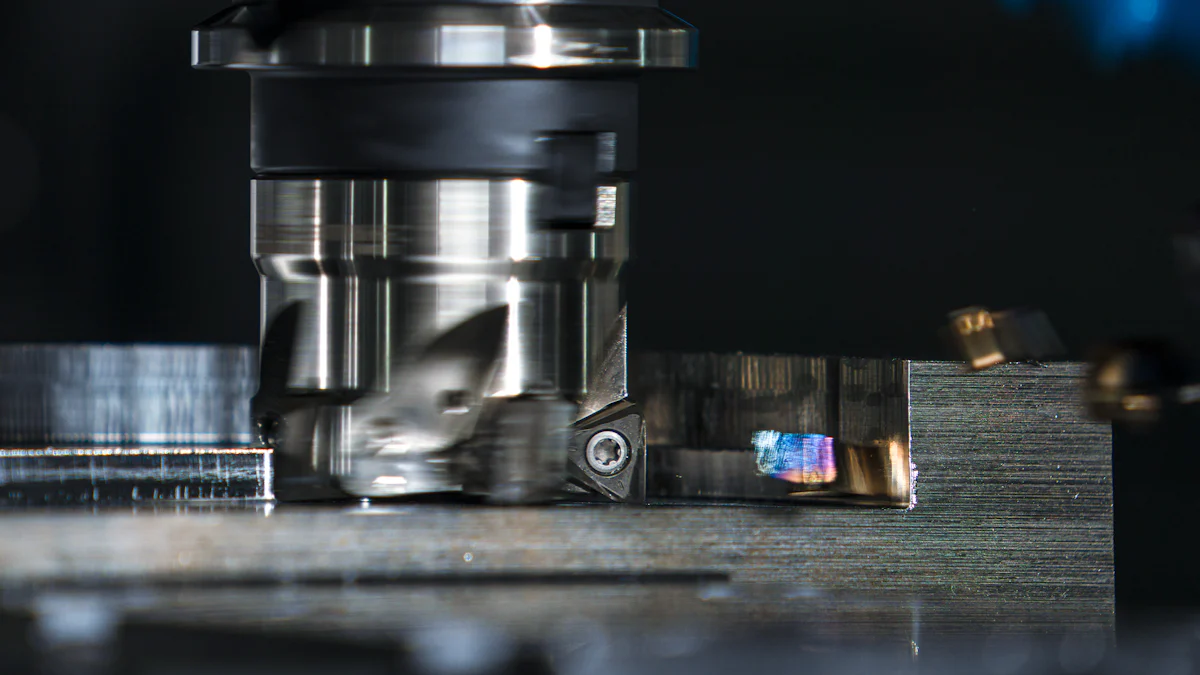

CNC machines, or Computer Numerical Control machines, are advanced tools that automate manufacturing processes. These machines use pre-programmed software to control their movements and operations. Unlike manual machining, CNC machines rely on precise instructions to perform tasks like cutting, drilling, and shaping materials. This automation eliminates human error and ensures consistent results.

CNC machines are essential in modern manufacturing because they handle complex designs with ease. They work with various materials, including metals, plastics, and composites. By using computer-aided manufacturing (CAM) software, you can create intricate parts that meet exact specifications. This makes CNC machines indispensable for industries requiring high precision and efficiency.

How CNC Machines Work

CNC machines operate by following a set of coded instructions, often referred to as G-code. These instructions guide the machine's movements, tool changes, and cutting paths. The process begins with designing a part using CAM software. Once the design is complete, the software generates the G-code, which the CNC machine reads to execute the task.

The core components of CNC machines play a vital role in their functionality. Here's a breakdown of these components and their purposes:

Component | Functionality |

|---|---|

Machine Control Unit | Controls servo motors, tool changers, and coolant activation. |

Machine Tools | Refers to cutting tools; varies by machine type (e.g., lathes vs. mills). |

Driving System | Motors that move tools; includes servo motors and ball screws for synchronization. |

Feedback System | Ensures accuracy through encoders and sensors; adjusts positions automatically if needed. |

Display Unit | Shows machine settings, G-code, and operating status on a screen. |

Bed | Holds raw material in place; may have t-slots for jigs. |

Headstock | Houses main drive and gears in a CNC lathe; spins the chuck. |

Tailstock | Supports one end of long workpieces; moves along the z-axis. |

Tailstock Quill | Keeps material centered; pushed in by pneumatic or hydraulic pressure. |

Footswitch or Pedal | Activates/deactivates chuck and tailstock quill; primarily used in lathes. |

Chuck | Grips workpiece in lathes; can have three or four jaws for different functionalities. |

Control Panel | Houses input devices and controls; serves as the brain of the machine. |

These components work together to ensure precision and efficiency during the machining process.

Types of CNC Machines

CNC machines come in various types, each designed for specific tasks. Here are the most common types used in modern manufacturing:

Pick and Place Machine

CNC 3D Printer

CNC Router

CNC Drilling Machine

CNC Lathe Machine

5-Axis CNC Machine

CNC Milling Machine

CNC Plasma Cutting Machine

CNC Laser Cutting Machine

Electric Discharge CNC Machine

CNC Grinding Machine

CNC Machine with Automatic Tool Changes

Each type serves a unique purpose. For example, CNC routers excel at cutting softer materials like foam, while CNC milling machines handle heavy-duty materials like steel and titanium. Understanding these types helps you choose the right machine for your manufacturing needs.

Transitioning from Traditional to CNC Machining

Challenges of Traditional Manufacturing

Traditional manufacturing methods often rely on manual labor and basic machinery, which can limit efficiency and precision. You may face challenges like inconsistent quality due to human error. For example, manual machining depends heavily on the operator's skill, making it difficult to achieve uniform results across multiple parts.

Another issue is the time-consuming nature of traditional processes. Setting up machines, adjusting tools, and performing repetitive tasks manually can slow down production. Additionally, balancing speed and quality becomes a constant struggle. Increasing production speed often compromises the final product's accuracy and finish.

You might also encounter difficulties with complex designs. Traditional tools lack the flexibility to handle intricate geometries, requiring advanced fixturing solutions that increase costs and time. Moreover, maintaining quality control across large-scale production can be resource-intensive.

The Rise of CNC Technology

The rise of CNC technology revolutionized manufacturing by addressing these challenges. This transformation began in the 1940s with the conceptualization of automated machining. By 1952, MIT introduced the first Numerical Control (NC) machine, marking a significant leap forward. The 1970s saw the integration of microprocessors, making CNC machines more efficient and accessible. By the 1980s, graphical user interfaces (GUIs) enhanced their usability, allowing you to operate them with ease.

CNC technology emerged from the need for greater precision and efficiency, particularly in industries like aerospace and defense. These advancements enabled manufacturers to automate processes, reduce errors, and produce complex parts with unmatched accuracy.

Key Differences Between Manual and CNC Machining

CNC machining offers several advantages over manual methods. First, it achieves exceptional precision, often reaching tolerances to a thousandth of an inch. In contrast, manual machining relies on the operator's skill, resulting in variable accuracy.

CNC machines also excel in efficiency. They automate tasks, reducing setup times and producing parts 75 to 300% faster than manual methods. This speed allows you to meet tight deadlines without sacrificing quality. Manual machining, on the other hand, is slower and better suited for small batches or prototypes.

Another key difference lies in scalability. CNC machines can handle large-scale production with consistent results, while manual methods struggle to maintain uniformity across high volumes. By adopting CNC technology, you can streamline operations, minimize waste, and boost productivity.

Benefits of CNC Machines in Manufacturing

Precision and Accuracy

CNC machines excel in delivering unmatched precision and accuracy, making them indispensable in the manufacturing industry. These machines can execute cuts and position tools with tolerances as tight as 0.001 inches (0.025mm). This level of precision is nearly impossible to achieve with manual methods. Once programmed, CNC machines can produce identical parts repeatedly, ensuring consistent quality across large production runs.

You can rely on CNC technology to eliminate human error, which often compromises the accuracy of manual machining. These machines handle complex operations with ease, producing precision components that meet exact specifications. Industries requiring zero defects, such as aerospace and medical device manufacturing, benefit significantly from this capability. By using CNC machines, you ensure that every part maintains consistent size, shape, and tolerance, regardless of operator skill levels.

Efficiency and Productivity

CNC machines revolutionize manufacturing efficiency by automating processes and reducing production times. For instance, a task that takes 30 minutes per part with manual machining can be completed in just 10 minutes using CNC technology. Over a batch of 100 parts, this reduces total production time from 50 hours to 17 hours.

These machines operate at higher speeds and with greater consistency than manual methods. Once programmed, they can run continuously, allowing you to meet tight deadlines without compromising quality. CNC technology also minimizes reliance on operator skill, ensuring consistent results across all production cycles. By enhancing machining efficiency, CNC machines enable you to produce custom parts quickly and at scale, boosting overall productivity.

Cost Reduction and Waste Minimization

CNC machines significantly reduce production costs and material waste, making them a cost-effective solution for the manufacturing industry. These machines optimize cutting paths and maximize material utilization, resulting in minimal scrap rates. Their precision and repeatability ensure that errors are rare, further reducing waste.

Automation in CNC technology lowers labor costs by requiring fewer operators. Continuous operation also optimizes spindle utilization, increasing output while minimizing downtime. Additionally, CNC machines streamline production processes, improving manufacturing efficiency and reducing overall costs. By adopting CNC technology, you not only save money but also contribute to sustainable manufacturing practices by minimizing material waste.

Flexibility and Scalability

CNC machines offer unmatched flexibility and scalability, making them a cornerstone of modern manufacturing. These machines adapt to changing production needs with ease, whether you are creating a single prototype or managing a large-scale production run. Their ability to handle diverse tasks ensures that you can meet customer demands without compromising quality or efficiency.

One of the key advantages of CNC machines is their ability to scale operations seamlessly. You can increase production speed and output as demand rises without sacrificing accuracy. This capability allows you to respond quickly to market changes while maintaining consistent results. Additionally, CNC machines operate continuously without breaks, ensuring high efficiency and faster production cycles.

Flexibility is another hallmark of CNC technology. These machines allow for rapid product changeovers, enabling you to switch between different designs with minimal downtime. Most programming is done offline, so you can make quick edits and adjustments without disrupting ongoing operations. This feature is especially useful when creating custom packaging designs or handling small batch orders.

CNC machines improve throughput by increasing speed and output as production demand rises.

They minimize human intervention, allowing workers to focus on strategic tasks.

Existing machines can be reprogrammed to enhance capacity, reducing the need for additional physical space.

Common tools and adequate storage reduce setup times, lowering part costs.

CNC machines also excel in resource allocation. By automating repetitive tasks, they free up your workforce to focus on more strategic activities. This not only boosts productivity but also ensures efficient use of resources. Whether you need to produce intricate prototypes or high-volume parts, CNC machines provide the flexibility and scalability to meet your goals.

With CNC technology, you can adapt to evolving manufacturing needs while maintaining precision, efficiency, and cost-effectiveness.

Applications of CNC Machines Across Industries

Automotive and Aerospace

CNC machines play a vital role in the automotive and aerospace sectors, where precision and consistency are critical. In the automotive industry, you can use CNC machines to manufacture engine blocks, transmission parts, and suspension components. These machines ensure the production of millions of identical parts with minimal variation, which is essential for maintaining quality in mass production. For example, CNC machining allows for the precise fabrication of engine blocks made from aluminum alloy, ensuring that moving pistons operate smoothly.

In aerospace, CNC machines enable the creation of complex components from materials like steel, aluminum, and titanium. These materials are essential for building lightweight yet durable aircraft parts. You can also use CNC technology for rapid prototyping, which accelerates the development of new designs. This capability allows engineers to test and refine components before full-scale production, fostering innovation in the aerospace industry.

Medical and Healthcare

The medical and healthcare sectors rely heavily on CNC machines for producing high-precision components. These machines minimize errors and maintain tight tolerances, reducing the risks associated with device malfunctions. For instance, CNC machining ensures that implants fit better, improving patient outcomes after surgeries. You can also use CNC technology to create patient-specific implants and surgical guides, which enhance comfort and recovery.

CNC machines offer flexibility in material choice, allowing you to work with metals, plastics, and biocompatible materials. This versatility supports the production of diverse medical devices, from prosthetics to surgical instruments. Additionally, the repeatability of CNC machining ensures consistent quality, which is crucial for patient safety. By streamlining production processes, CNC machines reduce lead times, enabling faster development of innovative medical solutions.

Electronics and Consumer Goods

In the electronics and consumer goods industries, CNC machines provide the precision needed for intricate designs. These machines achieve tight tolerances, ensuring accurate assembly of electronic components. For example, you can use CNC machining to produce both plastic and metal parts for smartphones, laptops, and other devices.

CNC technology also supports rapid prototyping, allowing you to test and optimize designs before mass production. This capability reduces lead times, helping manufacturers bring products to market faster. Additionally, CNC machines offer scalability, enabling you to produce parts in varying quantities without changing setups. This flexibility makes CNC machining ideal for meeting the dynamic demands of the electronics and consumer goods sectors.

CNC machines have become indispensable across industries by delivering precision, efficiency, and adaptability. Whether you are in automotive, healthcare, or electronics, these machines empower you to innovate and meet the challenges of modern manufacturing.

Prototyping and Custom Manufacturing

CNC machines have transformed prototyping and custom manufacturing by offering unmatched speed and precision. When creating prototypes, you can use CNC technology to identify design flaws early in the process. This helps you avoid costly mistakes before moving to full-scale production. Rapid prototyping with CNC machines allows you to test and refine designs quickly, ensuring your final product meets exact specifications.

You can rely on CNC machining for affordable and efficient prototyping. These machines produce prototypes with high accuracy, reducing human error and minimizing delays. For example, CNC technology enables you to create intricate parts with tight tolerances, ensuring every detail aligns with your design. This precision is especially valuable when developing complex components for industries like aerospace or medical devices.

CNC machines help you identify design flaws during prototyping.

They allow for quick adjustments, saving time and resources.

Rapid prototyping ensures faster turnaround times for creating prototypes.

You can develop custom dies and molds for unique product shapes.

Custom manufacturing also benefits from the flexibility of CNC machines. Whether you need a single part or a small batch of components, CNC technology adapts to your requirements. You can easily switch between designs without significant downtime, making it ideal for producing custom-made products. This adaptability ensures you meet specific customer demands while maintaining high-quality standards.

CNC machines streamline prototyping and custom manufacturing by enhancing speed, precision, and efficiency. Their ability to produce accurate prototypes and custom parts makes them an essential tool for modern manufacturing. With CNC technology, you can innovate confidently and bring your ideas to life.

Future of CNC Machines

AI and Machine Learning Integration

AI and machine learning are transforming CNC machines by making them smarter and more efficient. These technologies allow machines to learn from data and adapt to new instructions, improving their performance over time. For example, AI-powered CNC machines can automate repetitive tasks, ensuring consistent results while reducing the need for manual intervention.

You can also benefit from predictive maintenance, which uses AI to anticipate when a machine needs servicing. This reduces unexpected downtime and lowers production costs. Additionally, AI enables real-time data analysis, allowing CNC machines to suggest operational changes that boost productivity. By integrating AI and machine learning, you can achieve higher efficiency and precision in your manufacturing processes.

AI enhances long-term operational efficiency by enabling CNC machines to learn and adapt.

Predictive maintenance powered by AI minimizes downtime and reduces costs.

Real-time data analysis helps optimize production and improve consistency.

Additive Manufacturing and Hybrid Systems

Hybrid systems that combine CNC machining with additive manufacturing are revolutionizing production capabilities. These systems allow you to add material layers to existing parts, making them ideal for repairing expensive components. This versatility extends to working with a wide range of materials, enhancing the flexibility of your manufacturing processes.

“One great application with hybrid machines is they give manufacturers the ability to iterate,” says Phillips’ Hybrid Applications Manager Randy Behm. “Manufacturers can use these machines to print new parts and then machine them within the same set-up. This allows them design flexibility, so they can experiment with different geometries.”

Hybrid systems also accelerate product design timelines. Traditional methods may take over six months to develop a part, but hybrid machines can reproduce it in less than two weeks. This speed allows you to innovate faster and bring new products to market quickly.

IoT and Enhanced Connectivity

The Internet of Things (IoT) is enhancing CNC machines by improving connectivity and monitoring. IoT integration allows machines to connect with other devices, enabling seamless data exchange and real-time monitoring. Sensors collect data continuously, helping you identify issues and perform predictive maintenance.

IoT enables real-time monitoring and predictive maintenance, reducing downtime.

Machines can be monitored and controlled remotely, saving time and resources.

Data-driven decision-making improves efficiency and optimizes processes.

IoT technology also enhances productivity by automating data collection. This allows operators to focus on higher-value tasks, increasing overall efficiency. With IoT, you can future-proof your operations and adapt to evolving manufacturing needs.

By integrating IoT, AI, and hybrid systems, CNC machines are paving the way for a smarter, faster, and more connected future in manufacturing.

Sustainability in CNC Manufacturing

CNC machines play a vital role in promoting sustainability within the manufacturing industry. These machines are designed to optimize energy usage, reducing their environmental impact. By using energy-efficient systems, CNC machines consume less power during operations. This helps you lower energy costs while contributing to a more sustainable future.

You can also rely on CNC technology to minimize waste. These machines follow precise instructions, ensuring that raw materials are used efficiently. This reduces the amount of scrap generated during production. Additionally, many CNC operations incorporate recycling strategies, allowing you to reuse leftover materials. This approach supports a circular economy, where resources are conserved and waste is minimized.

The integration of renewable energy sources further enhances the sustainability of CNC machining. By powering machines with solar or wind energy, you can decrease reliance on non-renewable resources. This shift not only reduces the carbon footprint of your operations but also aligns with global efforts to combat climate change.

Energy-efficient CNC machines optimize power usage, lowering environmental impact.

Recycling and waste reduction strategies support a circular economy.

Renewable energy sources, like solar and wind, reduce carbon emissions.

Sustainability in CNC manufacturing also extends to fostering a culture of environmental responsibility. Training employees on sustainable practices ensures that your operations remain eco-friendly. For example, workers can learn to monitor energy consumption and implement waste reduction techniques. This creates a workplace that prioritizes sustainability at every level.

By adopting CNC technology, you can align your manufacturing processes with sustainability goals. These machines not only improve efficiency but also help protect the environment. Whether through energy savings, waste reduction, or renewable energy use, CNC machines empower you to create a greener future.

CNC machines demonstrate that advanced technology and sustainability can go hand in hand, paving the way for eco-friendly manufacturing practices.

CNC machines have revolutionized manufacturing by automating processes and improving precision. Their evolution, from punch cards to advanced software programming, has enabled faster setups and last-minute design changes. These machines have significantly boosted efficiency, reduced waste, and enhanced production quality. Across industries, their impact is evident in rapid prototyping, customization, and cost-effective production. In 2022, the CNC machine market reached $55.1 billion, reflecting their growing influence. As technology advances, CNC machines will continue to drive innovation and sustainability, shaping the future of manufacturing with smarter, more efficient systems.

FAQ

What industries benefit the most from CNC machines?

CNC machines are widely used in industries like automotive, aerospace, medical, electronics, and consumer goods. You can rely on them for precision, efficiency, and scalability, making them essential for producing high-quality components and prototypes in these sectors.

How do CNC machines improve manufacturing efficiency?

CNC machines automate repetitive tasks, reducing production time and errors. You can program them to run continuously, ensuring consistent results. This automation allows you to meet tight deadlines while maintaining high-quality standards, boosting overall productivity.

Can CNC machines handle custom designs?

Yes, CNC machines excel at creating custom designs. You can program them to produce unique parts with intricate details. Their flexibility allows you to switch between designs quickly, making them ideal for prototyping and small-batch manufacturing.

Are CNC machines environmentally friendly?

CNC machines promote sustainability by minimizing material waste and optimizing energy use. You can also integrate renewable energy sources, like solar or wind, to power them. These features make CNC technology an eco-friendly choice for modern manufacturing.

What skills are needed to operate a CNC machine?

To operate a CNC machine, you need basic programming knowledge, familiarity with CAD/CAM software, and an understanding of machining processes. With proper training, you can master these skills and efficiently manage CNC operations.

Tip: Many online courses and certifications can help you learn CNC programming and operation.

See Also

Understanding CNC Technology's Role in Modern Manufacturing Processes

The Evolution of Precision Manufacturing Through CNC Machining

CNC Machining's Influence on Innovative Toy Production Techniques

Comparing CNC and Traditional Manufacturing Across Various Sectors

A Guide to CNC Machining Services for Accurate Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com