The Impact of Material Shortages on CNC Projects

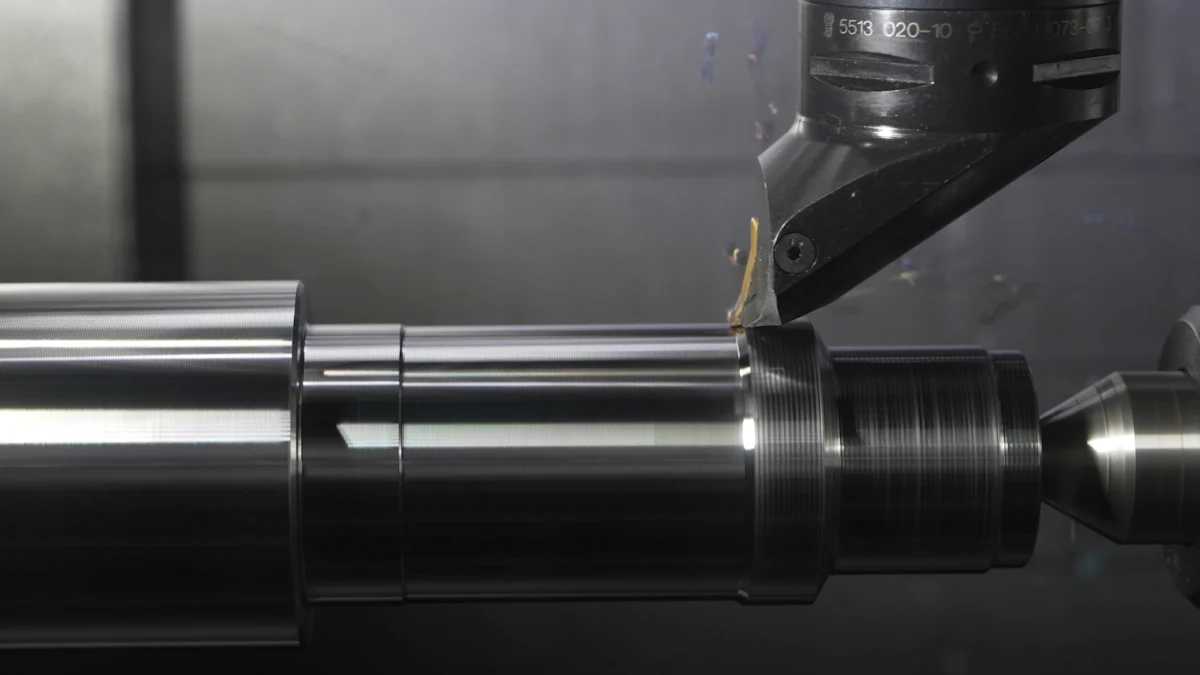

Material shortages have become a pressing challenge in CNC machining. You may have noticed how disruptions in global supply chains have caused significant delays in material availability. These delays often extend project timelines, increase costs, and disrupt production efficiency. For example, CNC shops frequently face idle machines due to a lack of materials, which raises operational expenses and impacts customer satisfaction. Supply delays also lead to higher labor costs and expedited shipping fees. To overcome these challenges, you need effective strategies that ensure smoother operations and minimize the impact of supply delays on your CNC projects.

Key Takeaways

Lack of materials can slow CNC projects and raise costs.

Working with many suppliers reduces risks and keeps materials steady.

Tracking materials with software helps avoid running out or overstocking.

Using different materials can keep work going without losing quality.

Talking to clients early about delays builds trust and sets expectations.

Causes of Material Shortages in CNC Machining

Supply Chain Disruptions in the CNC Machining Supply Chain

Global shipping delays and port congestion

You’ve likely noticed how global shipping delays have become a significant obstacle in CNC machining. Trade distortions and the COVID-19 pandemic exposed weaknesses in logistics networks, leading to backlogged orders and delayed deliveries. Port congestion further complicates the timely arrival of raw materials, which are essential for maintaining smooth production. Transportation issues, such as limited container availability, often prevent you from receiving materials on time. These disruptions can halt operations, increase costs, and create inefficiencies in material sourcing.

Dependence on international suppliers

Relying heavily on international suppliers can make material sourcing unpredictable. Many CNC machining businesses depend on overseas providers for raw materials, which increases vulnerability to global events. Natural disasters, geopolitical tensions, or even minor logistical hiccups can disrupt supply chains. Without stable sourcing, you may face delays that affect your ability to meet deadlines and maintain client satisfaction. Identifying reliable suppliers and diversifying your sourcing strategy can help mitigate these risks.

Global Events and Their Impact

Pandemics disrupting production and logistics

The COVID-19 pandemic highlighted how global events can disrupt CNC machining. Lockdowns and reduced workforce availability slowed production and delayed shipments. Factories operated with limited capacity, which created bottlenecks in material sourcing. Increased demand for medical equipment, such as ventilators, further strained the supply chain. These challenges forced many businesses to reorganize their operations and rethink their sourcing strategies to ensure efficient material sourcing in the future.

Geopolitical tensions and trade restrictions

Geopolitical tensions often lead to trade restrictions, which can severely impact CNC machining. High tariffs and sanctions disrupt the flow of materials, making it harder to source critical components. For example, restrictions on advanced technologies have limited access to high-end CNC tools in some regions. These barriers can increase costs and delay production timelines, making it essential for you to plan ahead and explore alternative sourcing options.

Production Inefficiencies in Material Supply

Limited capacity of material suppliers

Material suppliers often operate at limited capacity, which can create bottlenecks in the CNC machining supply chain. When demand exceeds supply, you may experience delays in receiving materials. Poor inventory management by suppliers can further exacerbate these issues, leaving you with fewer options for efficient material sourcing. Building relationships with multiple suppliers can help you navigate these challenges more effectively.

Resource scarcity and environmental regulations

Resource scarcity and strict environmental regulations also contribute to material shortages. For example, mining restrictions and sustainability initiatives can limit the availability of raw materials. These constraints make it harder for suppliers to meet demand, leading to delays in CNC machining projects. By exploring alternative materials and adopting sustainable practices, you can reduce your reliance on scarce resources and maintain steady production.

The Impact of Material Shortages on CNC Projects

Delays in CNC Machining Operations

Extended lead times for material procurement

Material shortages often result in extended lead times for material procurement. This delay disrupts your ability to maintain smooth CNC machining operations. Supplier delivery delays, raw material quality issues, and poor inventory management can all slow down production progress. These factors ultimately affect delivery timelines for CNC machined parts.

Extended lead times create several challenges:

Production delays that hinder your ability to meet deadlines.

The need to adjust production scheduling and inventory management.

Increased pressure on process planning to accommodate material sourcing delays.

Disruptions in production schedules

When materials arrive late, production schedules face significant disruptions. You may need to reschedule machining processes, which can lead to inefficiencies. Downtime becomes unavoidable as machines sit idle, waiting for raw materials. This disruption not only delays the delivery of CNC machined parts but also impacts your overall production efficiency.

Increased Costs Due to Material Shortages

Rising prices of raw materials

Material shortages often drive up the prices of raw materials. Limited availability increases demand, which raises costs. For CNC machining businesses, this means higher expenses for sourcing essential materials. These rising costs can strain your budget and reduce profit margins.

Higher operational expenses caused by delays

Delays in material supply increase operational expenses. Stable raw material supply is critical for timely delivery of CNC machined parts. When suppliers fail to deliver on time, production progress slows down. Poor inventory management further exacerbates the issue, leading to additional costs for expedited shipping or overtime labor.

Operational Challenges in CNC Machining

Downtime in machining processes

Material shortages cause downtime in machining processes, which increases costs. Idle machinery consumes resources without contributing to production. This downtime disrupts production schedules and reduces overall productivity. Operational efficiency suffers as a result, making it harder for you to meet client expectations.

Difficulty meeting client deadlines and expectations

Material shortages directly impact your ability to meet client deadlines. Machines remain idle due to a lack of raw materials, delaying production. These delays in delivery not only affect customer satisfaction but also harm your reputation. Clients may lose trust in your ability to deliver CNC machined parts on time, which can lead to lost business opportunities.

Strategies to Mitigate the Impact of Supply Delays

Enhancing CNC Machining Supply Chain Management

Building relationships with multiple suppliers

Establishing strong relationships with multiple suppliers can safeguard your CNC machining operations from material shortages. By diversifying your supplier base, you reduce the risk of disruptions caused by delivery delays or supply chain bottlenecks. Partnering with geographically diverse suppliers ensures that a localized issue, such as a natural disaster or geopolitical tension, does not halt your production. Collaborating with certified suppliers also guarantees high-quality raw materials, which is essential for producing reliable CNC machined parts.

Investing in supply chain visibility tools

Supply chain visibility tools allow you to monitor and manage your material sourcing processes more effectively. These tools provide real-time updates on raw material supply, helping you anticipate potential delays and adjust your production scheduling accordingly. By adopting just-in-time inventory management, you can minimize waste and storage costs while ensuring that materials arrive precisely when needed. This approach aligns with modern CNC machining practices, enabling you to optimize efficiency and maintain steady production.

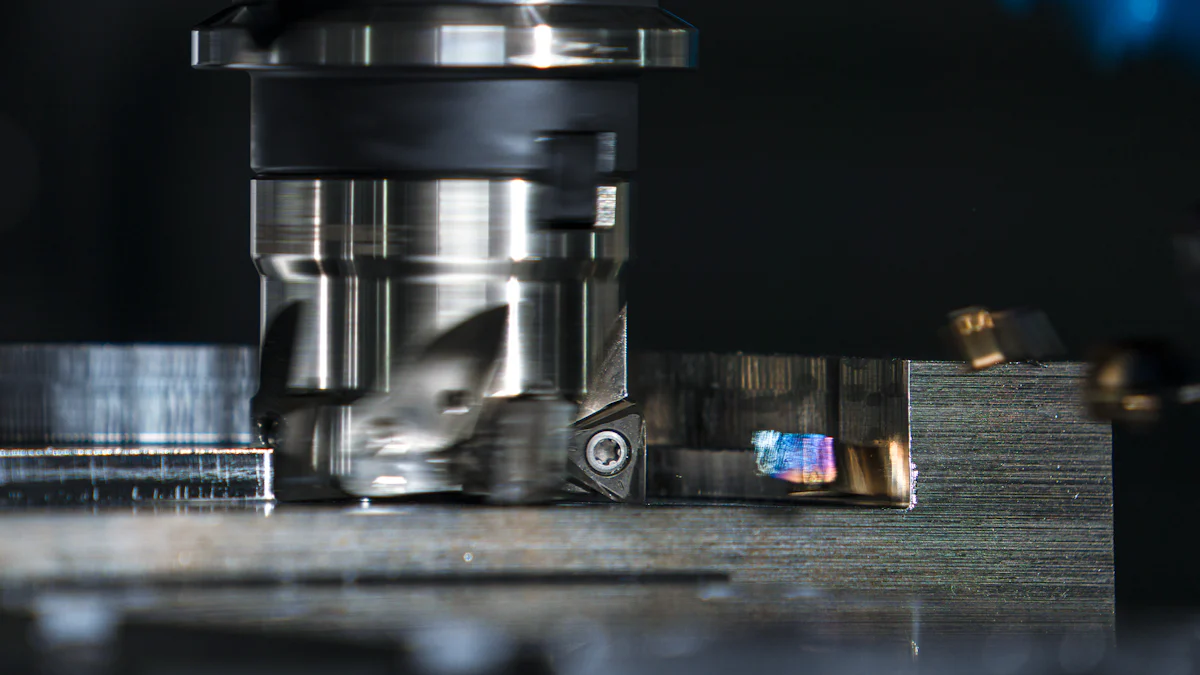

Exploring Alternative Materials for CNC Machining

Identifying substitutes with similar properties

Exploring alternative materials can help you overcome raw material shortages without compromising the quality of your CNC machined parts. For instance, aluminum offers excellent strength-to-weight ratio and corrosion resistance, making it a viable substitute for steel in many applications. Polymers, on the other hand, provide cost-effective solutions for lightweight components. By identifying materials with similar properties, you can maintain production continuity and meet client expectations.

Material | Properties and Applications |

|---|---|

Steel | High strength, good temperature dispersion, acceptable corrosion resistance. |

Aluminum | Good mechanical rigidity, excellent strength-to-weight ratio, natural corrosion resistance, can be anodized. |

Titanium | High rigidity and mechanical parameters, used in demanding applications like aerospace. |

Polymers | Broad group including alternatives to glass, efficient materials for lightweight parts, cost optimization. |

Wood | Commonly used in carpentry, especially in mass production with CNC devices. |

Testing and validating alternative materials

Before integrating alternative materials into your CNC machining processes, you must test and validate their performance. Conducting rigorous quality checks ensures that these substitutes meet the required specifications for your projects. Testing also helps you identify any potential challenges in machining these materials, allowing you to refine your process planning. This proactive approach minimizes risks and ensures the consistent delivery of high-quality CNC machined parts.

Leveraging Technology to Address Material Shortages

Using predictive analytics for demand forecasting

Predictive analytics can revolutionize your material sourcing strategy by providing accurate demand forecasts. Advanced data analysis tools and AI technologies enable you to predict customer demand, optimize inventory levels, and reduce delays. Machine learning algorithms analyze historical sales data and external factors, such as weather or market trends, to anticipate future demand patterns. This proactive approach shifts your operations from reactive to strategic, ensuring efficient material sourcing and uninterrupted CNC machining.

Implementing inventory management software

Inventory management software streamlines your operations by ensuring that the right materials are available when needed. These tools help you maintain optimal inventory levels, reducing the risk of overstocking or running out of critical raw materials. By integrating inventory management software into your CNC machining processes, you can improve production scheduling, minimize costs, and meet customer demand more effectively. This technology enhances your ability to deliver CNC machined parts on time, even during supply chain disruptions.

Strengthening Collaboration in CNC Projects

Proactively communicating with clients about timelines

Proactive communication with clients plays a vital role in managing expectations during material shortages. Keeping your clients informed about potential delays ensures transparency and builds trust. You should notify them early about any changes in production timelines caused by issues in raw material supply. Regular updates help clients understand the challenges you face and allow them to adjust their expectations accordingly.

Honest communication fosters stronger relationships. For example, sharing updates about delivery delays or price increases demonstrates your commitment to transparency. Engaging clients throughout the process also helps them feel involved in finding solutions. By discussing potential risks early, you can collaborate with clients to make quicker decisions, such as approving alternative materials or adjusting project scopes. This approach minimizes disruptions and ensures smoother delivery of CNC machined parts.

Partnering with suppliers for better resource planning

Strong partnerships with suppliers can significantly improve your resource planning and reduce the impact of material shortages. Collaborating with reliable suppliers ensures a steady flow of raw materials, even during supply chain disruptions. Many suppliers, especially those with ISO certifications, adhere to strict quality standards and use advanced CNC machines to produce precise parts. This reliability helps you maintain consistent production and meet client expectations.

Suppliers also offer flexibility in managing production runs. They can adapt quickly to changes in product specifications or sudden increases in demand. Some suppliers provide additional services like prototyping and finishing, which streamline your production process. These services save time and reduce costs, allowing you to focus on other aspects of your CNC machining operations. Partnering with suppliers who offer competitive pricing can also help you allocate resources more effectively, ensuring the timely delivery of CNC machined parts.

Tip: Building long-term relationships with suppliers and maintaining open communication can help you navigate challenges in material sourcing more efficiently.

Material shortages in CNC machining disrupt operations, increase costs, and challenge your ability to meet deadlines. Addressing these issues requires proactive planning and adaptability. You can strengthen supply chain resilience by fostering collaboration, maintaining optimal inventory levels, and building strong supplier relationships. Agile manufacturing practices and advanced technologies, like AI-powered systems, enable you to adjust production schedules and manage risks effectively. Diversifying suppliers and optimizing logistics further minimize disruptions. By adopting these strategies, you can ensure steady material flow, maintain production efficiency, and build a robust CNC supply chain prepared for future challenges.

FAQ

What are the most common materials used in CNC machining?

CNC machining commonly uses materials like aluminum, steel, titanium, and polymers. Each material offers unique properties suited for specific applications. For example, aluminum is lightweight and corrosion-resistant, while steel provides high strength. Polymers are cost-effective for lightweight parts.

How can you reduce downtime caused by material shortages?

You can reduce downtime by diversifying suppliers, maintaining safety stock, and using inventory management software. These strategies ensure a steady material flow and minimize disruptions in production schedules.

Are alternative materials as reliable as traditional ones?

Yes, alternative materials can be reliable if tested and validated. Substitutes like aluminum or polymers often match the properties of traditional materials. Proper testing ensures they meet project requirements without compromising quality.

How does predictive analytics help in CNC machining?

Predictive analytics forecasts material demand using historical data and trends. This helps you optimize inventory levels, avoid overstocking, and reduce delays. It shifts your operations from reactive to proactive, ensuring smoother production.

Why is supplier collaboration important in CNC machining?

Collaboration with suppliers ensures consistent material availability. Reliable suppliers adapt to changes in demand and provide high-quality materials. Strong partnerships also improve resource planning, helping you maintain production efficiency and meet deadlines.

Tip: Regular communication with suppliers strengthens relationships and helps you navigate supply chain challenges effectively.

See Also

Grasping Material Needs for CNC Precision Machining Success

Impact of CNC Precision Parts Processing on Production Expenses

Key Elements Influencing CNC Precision Parts Processing Costs

Addressing Challenges to Improve CNC Prototyping Precision and Speed

Clarifying Myths Surrounding CNC Milling Applications and Design

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com