The Importance of Material Choice in CNC Precision Manufacturing

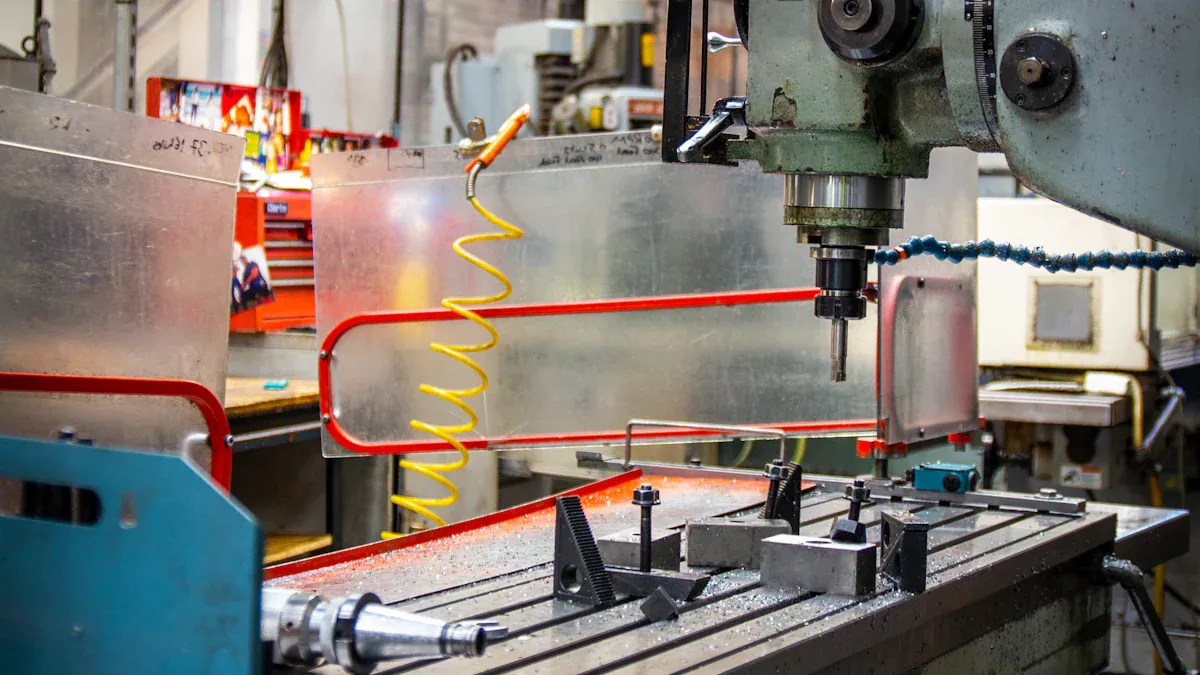

Material selection plays a vital role in CNC machining. The properties of your chosen material directly impact precision, quality, and efficiency. For example, machining titanium alloys can increase costs due to their hardness, while stainless steel may cause tool wear. Understanding material properties ensures durable, functional, and visually appealing CNC application materials.

Key Takeaways

Picking the right material is very important for CNC work. It impacts how accurate, strong, and efficient the process is. Use materials that fit your project to get great results.

Knowing how materials handle heat and pressure keeps things precise. Look at hardness and strength to avoid tool damage and keep the process steady.

Check how easy a material is to cut. Materials like aluminum are easier to machine, cut faster, and protect tools, saving both time and money.

The Role of Material Properties in CNC Machining

Mechanical Properties and Their Impact

Mechanical properties directly influence the performance of CNC machining. You must consider factors like hardness, tensile strength, and wear resistance when selecting a material. Hardness determines how well a material resists wear and shear forces, which is essential for maintaining precision. Tensile strength affects how much stress a material can handle without deforming, ensuring stability during machining. For example, materials like stainless steel and carbon steel, known for their strength and hardness, require slower machining speeds to reduce tool wear and maintain accuracy.

Here’s a quick overview of critical mechanical factors that impact CNC machining:

Mechanical Property | Description |

|---|---|

Machine Condition | Proper maintenance ensures components like spindles and guides remain aligned. |

Tooling | High-quality tools with minimal wear improve machining quality. |

Material Properties | Hardness and thermal properties affect the machining process. |

Cutting Parameters | Optimal speed, feed rate, and depth of cut enhance quality and tool life. |

CAD/CAM Accuracy | Precise CAD models and CAM paths are essential for accurate machining. |

Thermal Properties and Precision

Thermal properties play a significant role in CNC machining precision. Materials expand when exposed to heat, which can lead to errors in the final product. You must manage thermal expansion to avoid distortions and defects. High temperatures and friction during machining can worsen these issues, especially in industries like aerospace, where precision is critical. For instance:

Thermal expansion can cause inaccuracies in tolerance measurements.

Friction and heat buildup during machining exacerbate expansion problems.

Precision grinding processes are particularly sensitive to even minor thermal changes.

By understanding a material’s thermal behavior, you can select the right cnc application material to maintain accuracy and performance.

Material Composition and CNC Tool Compatibility

Material composition determines how well a material interacts with CNC tools. Strong, hard materials like stainless steel and carbon steel resist wear but can cause faster tool degradation. These materials often require slower machining speeds to prevent damage. On the other hand, wear-resistant materials like aluminum alloys demand sharp tools and precise speeds to avoid defects. When choosing a cnc application material, you should evaluate its composition to ensure compatibility with your tools and machining process.

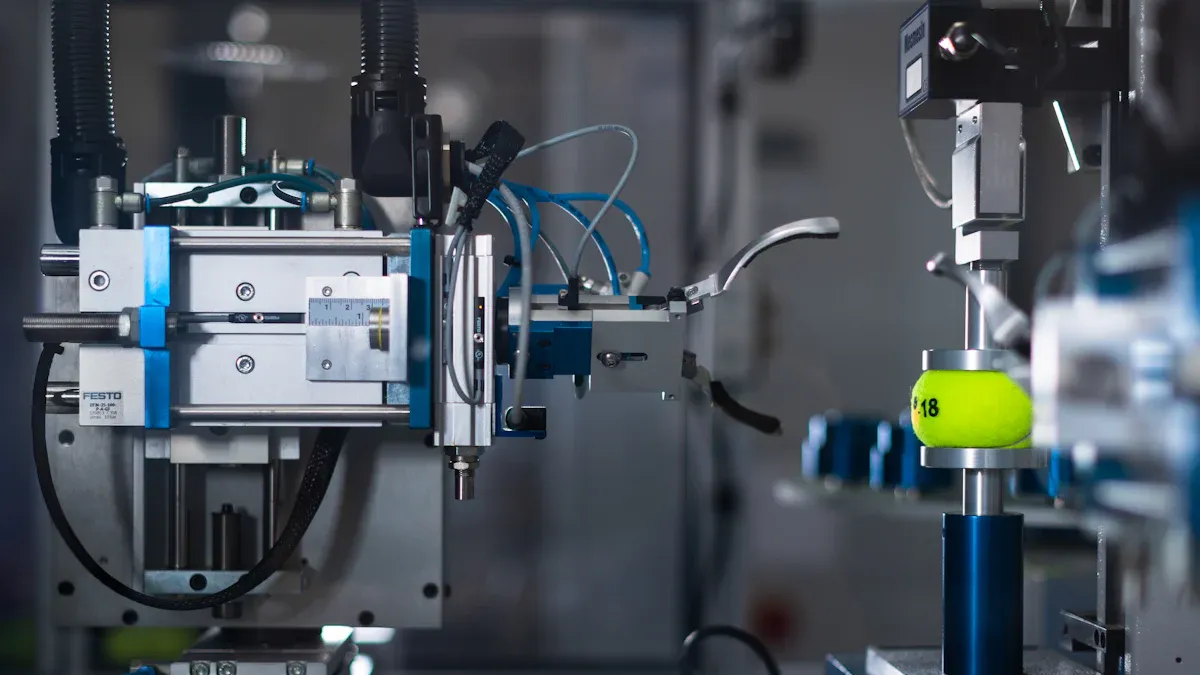

Common CNC Application Materials and Their Uses

Metals: Strength and Versatility

Metals are among the most widely used materials in CNC machining due to their strength, durability, and versatility. Each metal offers unique benefits, making it suitable for specific applications. For example:

Metal | Benefits | Applications/Industries Used |

|---|---|---|

Aluminum | Improved corrosion resistance, good formability, quick machining, economical | Automotive, aerospace, healthcare, medical devices |

Alloy Steel | High strength, heat treatable, enhanced formability | Automotive, aerospace, energy applications |

Stainless Steel | Strong, corrosion-resistant, machinable | Consumer products, industrial applications, aerospace |

Titanium | Tough, lightweight, corrosion-resistant | Medical equipment, aerospace, military |

Copper | Excellent electrical/thermal conductivity | Electrical components, wiring, marine hardware |

Aluminum stands out for its lightweight nature and corrosion resistance, making it ideal for automotive and aerospace industries. Stainless steel, known for its strength and machinability, is often used in surgical tools and industrial equipment. Titanium, with its toughness and biocompatibility, is a preferred cnc application material for medical implants and aerospace components. These metals ensure high-quality machined components across various industries.

Plastics: Lightweight and Cost-Effective

Plastics are another popular choice for CNC machining, especially when you need lightweight and cost-effective solutions. Commonly used plastics include:

ABS (Acrylonitrile Butadiene Styrene): Lightweight, impact-resistant, and ideal for rapid prototyping.

Acetal/POM (Polyoxymethylene): Offers high hardness and chemical resistance, making it suitable for precision parts.

Acrylic/PMMA (Poly(methyl methacrylate)): Transparent and strong, often used in display cases and lenses.

Nylon/PA (Polyamides): Heat-resistant and elastic, perfect for gears and bearings.

PTFE (Polytetrafluoroethylene): Known for its chemical resistance, used in seals and gaskets.

Plastics provide excellent machinability and reduce tool wear, ensuring efficient production cycles. Their versatility makes them a reliable cnc application material for industries like electronics, automotive, and healthcare.

Composites: Specialized Applications

Composites combine two or more materials to create a product with enhanced properties. These materials are often used in specialized applications where performance is critical. Examples include:

Aerospace: Carbon fiber composites improve fuel efficiency and flight performance in aircraft and satellite panels.

Automotive: Glass and carbon fiber composites reduce weight and enhance safety in electric vehicles.

Medical Devices: Biocompatible composites are used in implants and surgical tools.

Sports Equipment: Carbon fiber composites enhance performance in bicycles, tennis rackets, and other high-end gear.

Composites offer unique advantages like lightweight strength and resistance to environmental factors. They are essential for creating high-quality machined components in industries requiring precision and durability.

Key Factors in Choosing the Right Material

Application-Specific Requirements

When choosing the right material, you must consider the specific needs of your application. Different industries demand unique material properties to ensure performance and durability. For example:

Aerospace components require lightweight materials like aluminum or titanium to improve fuel efficiency and maintain dimensional stability under extreme conditions.

Structural parts often use heavier materials like steel for added strength.

Electrical applications benefit from materials with high conductivity, such as copper, or insulating properties, like PTFE.

The operating environment also plays a critical role. High temperatures, chemical exposure, or moisture can affect material performance. Selecting a material that withstands these conditions ensures long-term reliability.

Cost and Budget Considerations

Material selection directly impacts your budget. High-performance materials, such as advanced plastics or metals, often come with higher costs. Additionally, setup and labor expenses can increase for complex designs requiring skilled operators. Balancing cost with functionality is essential. For instance, aluminum offers a cost-effective alternative to titanium in many applications without compromising quality. Always evaluate material availability to avoid delays and maintain production efficiency.

Machinability and Tool Wear

Machinability determines how easily a material can be cut, shaped, or finished. Materials with high machinability, like aluminum, allow faster cutting speeds and reduce tool wear. This improves efficiency and lowers production costs. Conversely, harder materials, such as tool steel, wear down tools quickly, requiring frequent replacements. Understanding machinability helps you optimize processes and achieve superior surface finishes while minimizing downtime.

Environmental and Regulatory Factors

Sustainability is becoming a key consideration in material selection. Using recycled metals like aluminum or biodegradable plastics reduces environmental impact and aligns with regulatory standards. These choices also offer long-term benefits, such as cost savings and improved brand image. For example, sustainable practices can attract eco-conscious clients and qualify your business for tax incentives. By prioritizing environmentally friendly materials, you contribute to cleaner production processes and a safer work environment.

Material selection forms the foundation of successful cnc machining. Choosing the right material ensures precision, efficiency, and cost-effectiveness. You can achieve better outcomes by aligning material properties with application needs. This approach improves machining efficiency, reduces tool wear, and enhances product durability. Understanding these factors simplifies the selection process and optimizes results.

FAQ

What are the benefits of using CNC machining for your projects?

CNC machining offers precision, repeatability, and efficiency. It ensures high-quality results for your cnc machining projects, reducing errors and improving production speed.

How do you choose the right material for CNC machining projects?

You should consider factors like application requirements, machinability, and cost. Aligning material properties with project needs ensures optimal performance and durability.

Can CNC machining handle complex designs?

Yes, CNC machining excels at producing intricate designs. It allows you to create detailed components for cnc machining projects with high accuracy and consistency.

See Also

The Significance of Precision in CNC Machining Processes

Key Material Considerations for CNC Precision Machining

Expertise in CNC Machining: Tolerances, Prototypes, and Materials

Achieving Precision in Parts Manufacturing Through CNC Machining

Investigating CNC Machining Solutions for Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com