The Latest Advancements in CNC Technology

Staying updated on advancements in CNC technology is essential for navigating today’s competitive manufacturing landscape. The global CNC machine market, projected to grow to $80.4 billion by 2028, reflects its increasing adoption. Automation reduces labor shortages by minimizing manual tasks, while lean manufacturing principles enhance efficiency and cut waste. CNC machining also supports sustainability by lowering material waste and energy consumption. These innovations not only address industry challenges but also redefine modern machining processes, enabling you to achieve greater precision, cost efficiency, and environmental responsibility.

Key Takeaways

CNC technology is important for making accurate and detailed parts.

Robots and automation in CNC work faster and make fewer mistakes.

Workers can spend time on smarter and more important tasks.

AI helps CNC machines by spotting problems early and working better.

Smart factories use IoT to watch machines and control them remotely.

This improves speed and cuts down on machine breaks.

CNC machining is greener by using less waste and saving energy.

It also uses materials that are better for the environment.

The Current Landscape of CNC Machining

Overview of CNC Technology Today

CNC technology has become a cornerstone of modern manufacturing. It enables you to produce highly precise and complex components across various industries. From aerospace to agriculture, CNC machining plays a critical role in creating parts with tight tolerances and consistent quality. For example, it is used to manufacture high-precision molds, engine components, and even optical transmitter parts. In agriculture, CNC machines produce tractor components and irrigation system parts. This versatility makes CNC machining indispensable in today’s industrial landscape.

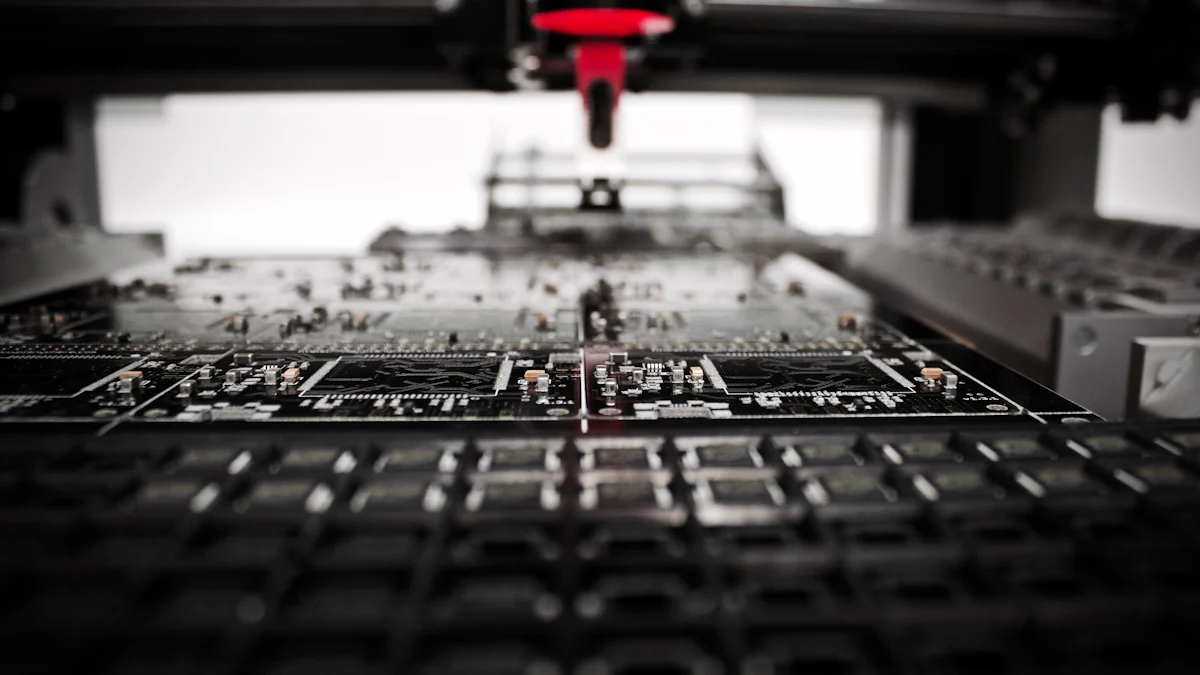

The applications of CNC technology extend beyond traditional manufacturing. It supports the production of robotic arms, sensors, and fixtures, which are essential for automation. Additionally, CNC machining is vital in electronics, where it helps create printed circuit boards (PCBs) and heat sinks. These examples highlight how CNC technology continues to evolve and adapt to meet the demands of diverse industries.

Key Industry Challenges

Labor Shortages and Workforce Gaps

The CNC machining industry faces a significant labor shortage. A quarter of the manufacturing workforce is over 55, and younger workers are not entering the field at the same rate. This aging workforce creates a gap in skilled labor, which impacts operational efficiency. The Society for Human Resource Management has identified this shortage as a critical challenge for the industry. With the sector expected to grow by 7.2% annually, addressing this issue becomes even more urgent.

Rising Costs and Efficiency Demands

High equipment and software costs pose another challenge. Advanced CNC machines require substantial investment, which can be prohibitive for small and medium-sized enterprises (SMEs). Additionally, selecting the right materials and optimizing designs are crucial for maintaining efficiency and controlling costs. These factors make it essential for you to carefully plan and allocate resources when adopting CNC machining technology.

Sustainability and Environmental Concerns

Sustainability is a growing concern in CNC machining. The industry must reduce waste and energy consumption to align with environmental goals. Energy-efficient CNC machines and eco-friendly materials are becoming more common, but their adoption requires careful consideration. By prioritizing sustainability, you can contribute to a greener future while maintaining competitive operations.

Automation and Robotics in CNC Machining

The Role of Automation in CNC Technology

Benefits of Automated CNC Systems

Automation plays a vital role in improving efficiency in CNC machining. By reducing the need for human intervention, automated systems allow you to achieve higher precision and productivity. These systems operate continuously without breaks, ensuring consistent output. Automation tools also provide real-time equipment status updates, helping you prevent potential issues before they escalate. This reduces downtime and enhances overall efficiency.

Automated CNC systems also ensure repeatability, minimizing errors and costly mistakes. For example, automation eliminates inconsistencies in multi-axis machining, enabling you to produce identical parts with tight tolerances. Additionally, automation reduces routine tasks, allowing your workforce to focus on strategic and creative responsibilities. This not only boosts job satisfaction but also enhances operational outcomes.

Examples of Robotic Integration in CNC Processes

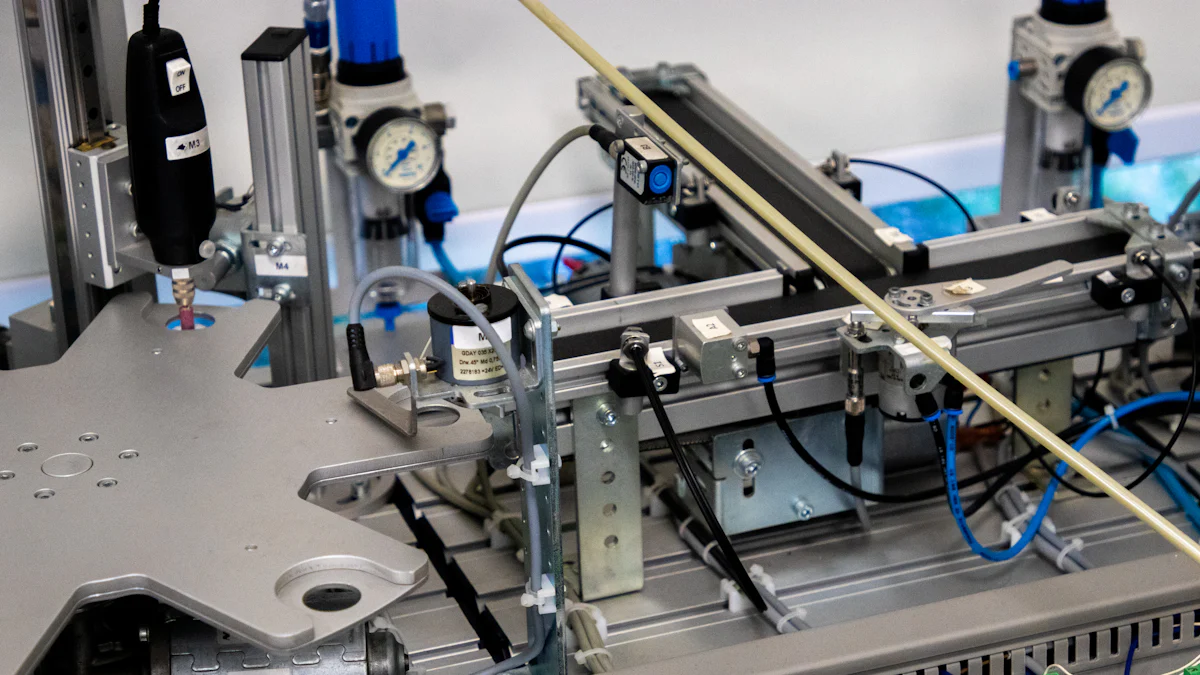

Robotics has become an integral part of CNC machining processes. Computer-controlled devices now handle tasks like drilling, milling, and welding with unmatched efficiency. For instance, the Haas robot package seamlessly integrates with CNC machines, enabling the mass production of high-quality parts. Robotic machining offers flexibility, especially for large or irregularly shaped workpieces in industries like automotive and aerospace.

Robotic milling is another example of successful integration. It allows for precise cutting and shaping, even for complex paths and detailed cuts. Systems like CubeBOX by Tezmaksan Robotics automate tasks such as loading, unloading, and quality inspections. These innovations streamline operations and enhance production capacity, making them indispensable in modern machining.

Enhancing Precision and Productivity with Robotics

Robotics significantly improves precision and productivity in CNC machining. Robots achieve precision levels between 0.1 and 0.2 mm, while advanced CNC machines can reach even tighter tolerances of 0.02 to 0.05 mm. This level of accuracy is crucial for industries requiring high-quality parts, such as aerospace and medical device manufacturing.

The versatility of CNC robots allows them to perform multiple tasks simultaneously, reducing production time. For example, robotic systems equipped with advanced sensors ensure consistent accuracy, even during continuous operation. Unlike human operators, robots do not experience fatigue, maintaining efficiency throughout the production cycle. By integrating robotics with CNC technology, you can achieve faster turnaround times and higher-quality outputs, meeting the demands of modern manufacturing.

Artificial Intelligence in CNC Machining Technology

AI-Driven Innovations in CNC

Predictive Maintenance and Error Reduction

Artificial intelligence is revolutionizing CNC machining by enabling predictive maintenance. AI algorithms analyze vast amounts of data generated by CNC machines to forecast potential equipment failures. This proactive approach allows you to address issues before they disrupt operations. For example, AI systems monitor tool wear, motor load, and machine vibration in real-time. By identifying subtle patterns, these systems can predict when a tool needs replacement or when a machine requires servicing. This reduces unexpected downtime by up to 40% and lowers maintenance costs by 25%.

AI-driven diagnostics also enhance error reduction. Advanced analytics and machine learning algorithms improve machining accuracy by optimizing cutting conditions. Real-time monitoring ensures that even minor deviations are corrected immediately, minimizing defects. This level of precision is crucial for industries like aerospace and medical device manufacturing, where quality cannot be compromised.

Adaptive Machining and Real-Time Adjustments

AI introduces adaptive machining capabilities, allowing CNC machines to adjust to changing conditions in real-time. Sensors installed on CNC equipment continuously collect data, such as temperature, vibration, and cutting force. AI systems analyze this data to make instant adjustments, ensuring consistent quality. For instance, if a tool begins to wear, the system can modify cutting speeds or paths to maintain precision.

This adaptability also enhances efficiency. AI can optimize toolpaths and machining parameters based on real-time conditions, reducing cycle times and material waste. These innovations make CNC machining more flexible and responsive to market demands, helping you stay competitive in a rapidly evolving industry.

Practical Applications of AI in CNC Operations

AI has numerous practical applications in CNC machining. It improves precision and quality control by reducing defect rates through real-time data analytics. Predictive maintenance minimizes costs and downtime, while AI-driven scheduling enhances production efficiency by up to 20%. Additionally, AI enables advanced process automation, with nearly 70% of manufacturers reporting increased efficiency after adopting AI-enabled systems. These applications demonstrate how AI transforms CNC machining into a more reliable and efficient process.

AI also supports customization and flexibility. It allows you to quickly adjust production parameters, making it easier to meet unique customer requirements. This capability is especially valuable in industries like additive manufacturing, where rapid prototyping and small-batch production are common.

Trends in CNC Machining: Smart Manufacturing and IoT

The Rise of Connected CNC Machines

Real-Time Data Monitoring and Analysis

Connected CNC machines, powered by IoT, are transforming how you monitor and manage machining operations. These machines use real-time data from sensors to track performance, detect errors, and ensure consistent quality. For example, real-time monitoring helps you identify trends in machine behavior, allowing for quicker adjustments to maintain precision. This approach enhances product quality and reduces downtime by predicting potential failures before they occur.

The benefits of real-time data monitoring extend beyond error detection. It improves cost visibility by tracking machine utilization and operational efficiency. You can use this data to optimize production schedules and allocate resources more effectively. The result is a streamlined process that minimizes waste and maximizes productivity.

Benefit | Description |

|---|---|

Enhanced Product Quality | Real-time data from machine sensors helps detect errors quickly and monitor trends, improving quality and consistency in manufacturing. |

Reduced Downtime with Predictive Maintenance | Smart CNC machines use real-time data to predict potential failures, leading to fewer unexpected downtimes compared to traditional methods that rely on historical data. |

Improved Cost Visibility and Machine Utilization | Real-time data enhances cost traceability and allows for better tracking of machine availability, leading to efficiency gains and cost savings. |

Remote Operation and Predictive Maintenance

IoT integration allows you to operate CNC machines remotely, giving you greater flexibility and control. Operators can monitor machine conditions from anywhere and receive alerts for maintenance needs. Predictive maintenance, enabled by IoT, uses real-time data to forecast equipment issues. This proactive approach reduces downtime and extends the lifespan of your CNC machines. Unlike traditional maintenance schedules, predictive strategies avoid unnecessary interruptions by addressing problems before they escalate.

IoT also increases machine utilization by identifying downtime causes and improving training and quality control. Automation of data collection frees up your time for higher-value tasks, boosting overall productivity.

Benefits of Smart Manufacturing for CNC

Enhanced Efficiency and Reduced Downtime

Smart manufacturing leverages advanced technologies like AI and IoT to improve CNC machining efficiency. Predictive maintenance plays a key role by identifying potential failures early. This reduces unexpected downtime and extends machine life, saving you money in the long run. Real-time data solutions enable timely decision-making, ensuring fewer equipment outages compared to traditional methods.

By monitoring machine health continuously, smart CNC systems optimize performance and minimize disruptions. This approach contrasts with outdated methods that rely on historical data, which often leads to delayed responses. With smart manufacturing, you can achieve consistent production and reduced operational costs.

Data-Driven Decision-Making in CNC Processes

Data-driven decision-making is a cornerstone of smart manufacturing. Real-time data provides insights into machine performance, helping you identify areas for improvement. For example, monitoring trends in CNC operations allows you to detect errors quickly and enhance product quality. Predictive maintenance strategies based on this data prevent unexpected failures, reducing downtime and improving efficiency.

Cost visibility also improves with data-driven approaches. You can track expenses and machine availability more effectively, leading to better resource allocation. This level of insight empowers you to make informed decisions, ensuring your CNC machining processes remain competitive and efficient.

Smart manufacturing not only enhances operational efficiency but also supports customization. By leveraging data, you can adapt production to meet unique customer requirements, especially in fields like additive manufacturing.

Sustainability in CNC Machining Technology

Eco-Friendly Materials and Processes

Reducing Waste in CNC Machining

You can significantly reduce waste in CNC machining by adopting innovative processes and materials. Many manufacturers now reuse materials from recycled products and components. For instance, scrap metal can be repurposed for prototypes or test parts, minimizing material waste. Adaptive cutting techniques also optimize cutting paths using real-time feedback, which reduces waste and extends tool life. Laser cutting, with its precision and smaller cut widths, further minimizes material usage while improving cooling efficiency. These methods not only enhance sustainability but also improve overall machining efficiency.

Additionally, implementing a closed-loop system can help you recycle and reuse materials effectively. This approach aligns with global sustainability goals and reduces your ecological footprint. By integrating these practices, you contribute to a greener manufacturing process while maintaining high-quality outputs.

Energy-Efficient CNC Machines

Energy-efficient CNC machines play a crucial role in achieving sustainability goals. These machines operate with high precision, which minimizes material waste and ensures efficient resource use. Advanced technologies embedded in modern CNC systems optimize energy consumption, reducing emissions and pollution. For example, some CNC machines now incorporate renewable energy sources like solar or wind power, further lowering their carbon footprint. By using energy-efficient CNC technology, you can meet international climate targets and promote responsible resource use.

CNC’s Role in Supporting a Circular Economy

CNC machining supports the circular economy by promoting sustainable practices. It minimizes waste through optimized cutting patterns, ensuring maximum material usage. The precision of CNC machines also reduces energy consumption during operations. Some systems even utilize dry machining, which conserves water. Additionally, CNC machining often incorporates recycled materials, such as aluminum or biodegradable plastics, to create eco-friendly products. Many CNC machines can also operate using renewable energy, further enhancing their sustainability.

Role of CNC Machining in Circular Economy | Description |

|---|---|

Minimizing Waste | CNC machining reduces waste by optimizing cutting patterns to maximize material usage. |

Enhancing Energy Efficiency | The precision of CNC machines leads to lower energy consumption during operations. |

Conserving Water | Some CNC machines utilize dry machining, which reduces water usage. |

Utilizing Eco-Friendly Materials | CNC machining practices often incorporate recycled materials, promoting sustainability. |

Integrating Renewable Energy Sources | Many CNC machines can operate using renewable energy, such as solar or wind power. |

By adopting these practices, you can align your operations with circular economy principles, ensuring long-term sustainability in manufacturing.

Challenges and Considerations for Manufacturers

Cost Implications of Adopting Advanced CNC Technology

Adopting advanced CNC technology requires a significant initial investment. New machines with cutting-edge features, such as automated tool changers and multi-axis capabilities, cost approximately 30% more than traditional models. However, these machines offer long-term savings by reducing material waste and energy consumption. They also enhance machining precision and shorten production times, which can optimize overall costs. For example, high-end CNC systems improve productivity and reduce labor expenses, making them a worthwhile investment for manufacturers aiming to stay competitive.

While the upfront costs may seem daunting, the benefits outweigh the expenses over time. Advanced CNC machines consume less energy and generate less waste, aligning with sustainability goals. By carefully planning your budget and considering financing options, you can adopt these technologies without compromising your financial stability.

Workforce Training and Development Needs

The rapid evolution of CNC machining technology demands a skilled workforce. Training programs tailored to your business needs can help bridge the skills gap. For instance, CNCTS offers free assessments to identify training requirements and provides customized courses with flexible scheduling. These programs use state-of-the-art labs and interactive sessions led by industry experts to ensure effective learning.

Investing in training not only enhances your team’s efficiency but also boosts overall productivity. Programs designed to improve workplace performance often lead to cost savings and higher profitability. Additionally, CNCTS assists in identifying grants to offset training expenses, making it easier for you to upskill your workforce without incurring excessive costs.

Training Program Features | Description |

|---|---|

Free training assessments | CNCTS offers assessments to identify educational and training needs of businesses. |

Customized courses to meet unique needs | Training programs are tailored to the specific requirements of each organization. |

Flexible scheduling of courses | Courses can be scheduled to accommodate the needs of the businesses. |

State of the art training labs | Facilities equipped with modern technology for effective learning. |

Interactive, quality training from industry experts | Training is delivered by professionals with real-world experience. |

Balancing Innovation with Practicality in CNC Adoption

Balancing innovation with practicality ensures you adopt CNC machining technology effectively. Start by focusing on sustainability practices, such as using renewable energy and eco-friendly materials. Lean manufacturing principles, which emphasize waste reduction and process optimization, can also enhance efficiency. Investing in advanced digital tools and collaborative robots improves production capabilities while maintaining practicality.

Collaboration plays a key role in this balance. Partnering with technology providers gives you access to the latest advancements in CNC. Working with educational institutions ensures your workforce stays skilled in modern machining processes. Engaging with other manufacturers through joint ventures allows you to share resources and drive innovation collectively. These strategies help you embrace CNC advancements while maintaining operational feasibility.

Tip: Prioritize gradual implementation to avoid overwhelming your resources and workforce. This approach ensures a smoother transition to advanced CNC systems.

Recent advancements in CNC machining technology have transformed manufacturing. High-speed, high-precision machining allows you to produce intricate designs faster. Intelligent optimization algorithms and adaptive control systems reduce waste and improve efficiency. These innovations enable you to focus on quality while meeting modern production demands.

To stay competitive, you must embrace these advancements. Upgrading to the latest CNC technology ensures you remain efficient and adaptable. Establishing feedback loops refines processes and enhances productivity. Pilot programs help you test new systems before full-scale adoption. Leveraging IoT and cloud computing streamlines operations and improves decision-making.

By adopting these strategies, you can harness the full potential of CNC machining and drive sustainable growth.

FAQ

What is CNC machining, and why is it important?

CNC machining, or computer numerical control machining, uses automated tools to produce precise parts. It is important because it ensures high accuracy, repeatability, and efficiency in manufacturing. This technology supports industries like aerospace, automotive, and medical by delivering consistent, high-quality results.

How does multi-axis machining improve production?

Multi-axis machining allows tools to move in multiple directions, enabling the creation of complex shapes. It reduces the need for multiple setups, saving time and improving precision. This advanced technology is essential for industries requiring intricate designs, such as aerospace and additive manufacturing.

What are the latest trends in CNC machining?

The latest trends in CNC machining include smart manufacturing, IoT integration, and 3D printing. These technological innovations enhance efficiency, enable real-time monitoring, and support sustainable practices. By adopting these trends, you can stay competitive and focus on quality in your operations.

How does CNC technology support sustainability?

CNC technology supports sustainability by reducing waste and energy consumption. Energy-efficient machines, optimized cutting paths, and the use of recycled materials contribute to eco-friendly manufacturing. These practices align with global environmental goals and promote responsible resource use.

Can CNC machining integrate with 3D printing?

Yes, CNC machining integrates with 3D printing to create hybrid manufacturing systems. This combination allows you to leverage the precision of CNC with the flexibility of additive manufacturing. It is ideal for rapid prototyping, small-batch production, and creating complex parts.

See Also

Exploring Recent Innovations in CNC Processing Technologies

Understanding CNC Technology: Progress and Its Manufacturing Applications

CNC Machining Breakthroughs: Insights Into Precision Engineering

CNC Milling Innovations: Future Trends and Diverse Uses

The Impact of CNC Machining on Precision Manufacturing Excellence

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com