What Are the Major Components Created by CNC Machines?

In the realm of modern manufacturing, CNC machines stand as technological marvels driving precision and efficiency. Understanding the Key Components Produced by CNC Machines is paramount for grasping their intricate role in shaping various industries. The significance lies in the meticulous creation of vital components that form the backbone of diverse sectors, from aerospace to electronics. Delving into these Key Components Produced by CNC Machines illuminates the intricate web of innovation and precision that CNC machining offers to propel industries forward.

Basic Concepts of CNC Machining

Definition and Working Principle

CNC Machining:

CNC machining is a subtractive manufacturing technology that involves the precise removal of material from a solid block. This process utilizes cutting tools that rotate at high speeds to shape components based on a CAD model.

CNC Machine Operations:

CNC machines operate by following pre-programmed instructions to control the movement of the cutting tool. These instructions dictate the tool's path and depth, ensuring accurate and consistent production.

Types of CNC Machines

CNC Milling Machines:

Description: CNC milling machines use cutting tools to remove material from a workpiece accurately.

Operation: The workpiece remains fixed while the rotating cutting tool shapes it to specific dimensions.

CNC Lathes:

Description: CNC lathes are precision machines that rotate the workpiece while cutting tools shape it.

Operation: The turning action allows for intricate designs and symmetrical components to be produced efficiently.

CNC Routers:

Description: CNC routers utilize a rotating cutting tool to hollow out sections of material.

Operation: These machines excel in creating intricate patterns and detailed cuts in various materials.

CNC Plasma Cutters:

Description: CNC plasma cutters use an electrical discharge arc to melt materials accurately.

Operation: By ionizing the air with a plasma torch, these machines deliver precise cuts for various applications.

Major Components Created by CNC Machines

Engine Components

Cylinder Heads

CNC machines play a pivotal role in crafting Cylinder Heads for various engines. The precision and accuracy achieved through CNC machining ensure the optimal performance of these critical engine components. By meticulously shaping and refining the cylinder heads, CNC machines contribute to the seamless operation of internal combustion engines.

Engine Blocks

Engine Blocks, the foundation of any motorized vehicle, undergo intricate manufacturing processes with CNC machines. These robust components serve as the structural backbone of engines, requiring precise machining to accommodate various moving parts seamlessly. CNC technology enables the creation of durable and high-performance engine blocks that meet stringent industry standards.

Pistons

The production of Pistons demands exceptional precision to maintain engine efficiency and performance. CNC machines excel in fabricating pistons with intricate designs and specifications, ensuring a perfect fit within the engine cylinders. Through CNC machining, pistons are crafted to withstand high temperatures and pressures, contributing to the reliability and longevity of internal combustion engines.

Aerospace Components

Turbine Blades

Turbine Blades, crucial elements in aircraft propulsion systems, undergo meticulous manufacturing processes with CNC machines. The intricate profiles and aerodynamic shapes of turbine blades are precisely machined using advanced CNC technology. This precision ensures optimal performance, efficiency, and safety in aviation applications where turbine blades are subjected to extreme conditions.

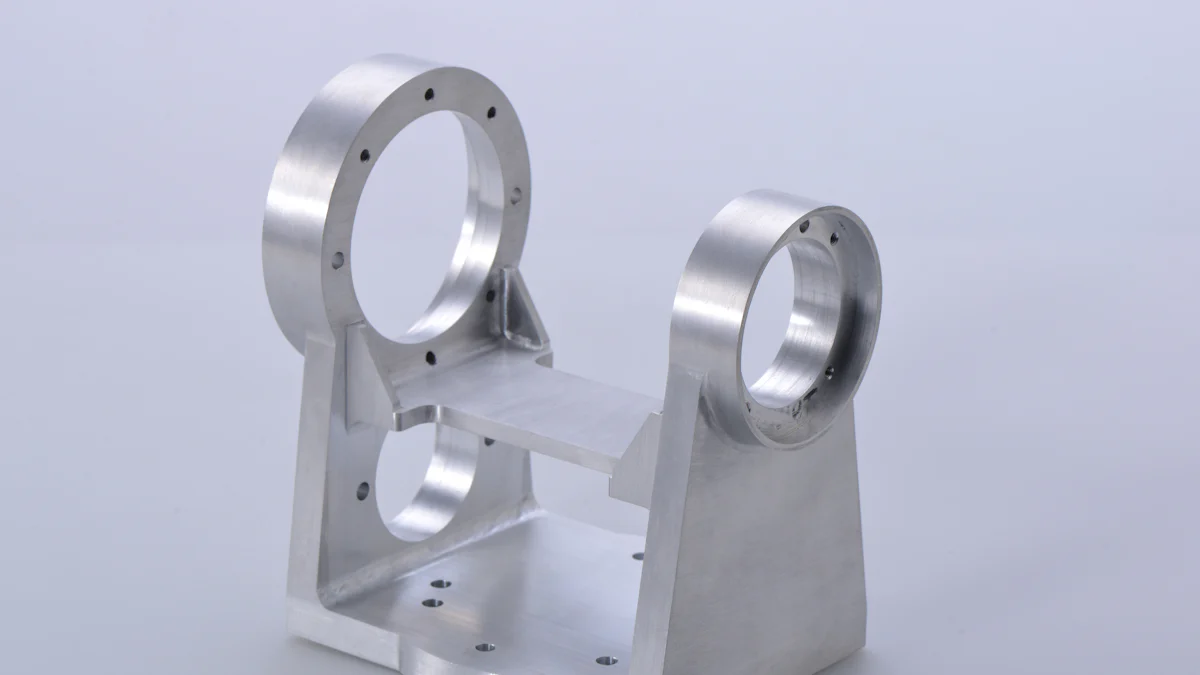

Structural Components

In the aerospace industry, Structural Components such as brackets, frames, and supports require superior strength and dimensional accuracy. CNC machining plays a vital role in producing these components with tight tolerances and complex geometries. By utilizing CNC technology, aerospace manufacturers can create lightweight yet durable structural components that enhance aircraft performance and safety.

Landing Gear Parts

The reliable operation of an aircraft's landing gear hinges on the quality of its Landing Gear Parts. CNC machines enable the precise fabrication of landing gear components that meet stringent aviation standards. From landing gear struts to wheels and brakes, each part is meticulously crafted using CNC machining techniques to ensure durability, reliability, and safety during takeoff and landing maneuvers.

Medical Devices

Surgical Instruments

Precision is paramount in the production of Surgical Instruments used in medical procedures worldwide. CNC machines offer unparalleled accuracy in crafting surgical instruments with intricate details and ergonomic designs. From scalpels to forceps, each instrument is meticulously manufactured using advanced CNC technology to meet the exacting requirements of healthcare professionals.

Implants

The creation of medical Implants demands exceptional precision and biocompatibility to ensure patient well-being. With CNC machining capabilities, implants such as orthopedic devices or dental fixtures are custom-made to exact specifications for individual patients. By leveraging advanced materials and design flexibility offered by CNC technology, medical implants can be tailored for optimal functionality and patient comfort.

Prosthetics

Customization is key in developing functional Prosthetics that restore mobility and improve quality of life for individuals with limb loss. Through CNC machining processes, prosthetic limbs are intricately designed to match individual anatomical structures while providing comfort and support. The versatility of CNC technology allows for personalized prosthetic solutions that enhance mobility and independence for users.

Electronic Components

Circuit Boards

Zintilon, an expert in CNC milling, emphasizes the critical role of precision machining in CNC milling for creating accurate and detailed parts. The integration of CAD/CAM software and precise programming techniques ensures the production of intricate Circuit Boards that meet industry standards. CNC machines meticulously carve out circuit patterns on boards, guaranteeing optimal functionality and reliability for electronic devices.

Enclosures

In the realm of CNC machining, Enclosures serve as protective casings for various electronic components, safeguarding them from external elements. CNC technology enables the precise fabrication of enclosures with intricate designs and custom specifications. These enclosures house sensitive electronics securely, ensuring durability and longevity in diverse applications.

Connectors

Connectors, essential components in electronic assemblies, require precision engineering to establish reliable connections between devices. CNC machines play a pivotal role in crafting connectors with exacting tolerances and complex geometries. By leveraging advanced machining capabilities, connectors are manufactured to ensure seamless electrical conductivity and compatibility across electronic systems.

Material Choices for CNC Machining

Metals

Aluminum

Aluminum, a versatile metal, is a popular choice in CNC machining due to its lightweight properties and excellent corrosion resistance. Its malleability allows for intricate designs to be precisely machined, making it ideal for various applications ranging from aerospace components to electronic enclosures.

Steel

Steel, known for its strength and durability, is a fundamental material in CNC machining. Its robust nature enables the fabrication of high-stress components such as engine parts and structural elements. With precise CNC techniques, steel components can be crafted with exceptional accuracy and reliability.

Titanium

Titanium, prized for its exceptional strength-to-weight ratio and biocompatibility, finds extensive use in medical implants and aerospace applications. CNC machining of titanium demands precision and expertise due to its challenging machinability. However, the superior properties of titanium make it a sought-after material for critical components requiring both strength and lightness.

Plastics

ABS

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic known for its impact resistance and versatility in CNC machining. This material is commonly used in producing electronic casings, automotive parts, and consumer goods. The ease of machining ABS allows for the creation of intricate shapes and detailed features with consistent quality.

Polycarbonate

Polycarbonate stands out for its transparency, high impact strength, and heat resistance—making it an ideal choice for optical components, protective gear, and electronic enclosures. CNC machining polycarbonate requires precision to achieve smooth finishes while maintaining structural integrity. The versatility of polycarbonate makes it a preferred material in various industries seeking durable yet visually appealing components.

Nylon

Nylon's toughness, flexibility, and chemical resistance make it a valuable material in CNC machining diverse components such as gears, bearings, and structural parts. Its self-lubricating properties reduce friction during operation while maintaining dimensional stability over time. With CNC technology optimizing the production process, nylon components exhibit high performance under demanding conditions.

Composites

Carbon Fiber

Carbon fiber composites offer exceptional strength-to-weight ratios that enhance performance in aerospace structures, automotive parts, and sporting equipment. CNC machining carbon fiber requires specialized tools to prevent delamination and ensure precise shaping of complex geometries. The unique properties of carbon fiber composites provide superior mechanical characteristics crucial for high-performance applications across industries.

Fiberglass

Fiberglass composites combine glass fibers with resins to create lightweight yet sturdy components suitable for marine applications, automotive panels, and construction materials. Precision CNC machining of fiberglass maintains dimensional accuracy while achieving intricate designs with consistent quality. The versatility of fiberglass composites offers durability and resilience in challenging environments where both strength and flexibility are essential.

Industry Applications of CNC Machined Components

Automotive Industry

Custom Parts

Precision CNC machining plays a vital role in crafting Custom Parts for the automotive industry.

Tailored components are meticulously manufactured to meet specific design requirements and performance standards.

The use of advanced CNC technology ensures the production of high-quality parts that enhance vehicle functionality.

Prototyping

In the realm of automotive innovation, Prototyping is a crucial stage where concepts are transformed into tangible models.

CNC machining facilitates rapid prototyping by accurately fabricating prototype parts for testing and validation.

This iterative process allows automotive engineers to refine designs efficiently before full-scale production.

Aerospace Industry

High-Precision Parts

The aerospace sector demands High-Precision Parts that adhere to stringent quality and safety regulations.

CNC machines excel in producing components with intricate geometries and precise tolerances required for aerospace applications.

By leveraging advanced machining capabilities, aerospace manufacturers achieve unparalleled precision in crafting critical aircraft parts.

Lightweight Components

Weight reduction is a key focus in aerospace engineering, driving the need for Lightweight Components with optimal strength-to-weight ratios.

CNC machining enables the creation of lightweight structures without compromising structural integrity or performance.

These components contribute to fuel efficiency, aerodynamic enhancements, and overall operational efficiency in the aerospace industry.

Medical Industry

Custom Implants

Personalized healthcare solutions rely on Custom Implants tailored to individual patient needs and anatomical specifications.

CNC machining offers exceptional precision in fabricating medical implants such as orthopedic devices or dental fixtures.

The customization capabilities of CNC technology ensure optimal fit, functionality, and biocompatibility of medical implants.

Precision Instruments

The medical field relies on Precision Instruments for accurate diagnostics and surgical procedures.

CNC machines play a pivotal role in manufacturing intricate instruments with exceptional accuracy and reliability.

From scalpels to forceps, these precision instruments undergo meticulous fabrication processes to meet the exacting standards of healthcare professionals.

Machining complex components with CNC technology showcases the pinnacle of precision and versatility in manufacturing. Achieving incredible tolerances and meeting exact specifications for various industries' critical components exemplifies the power of CNC machining. The future of this innovative technology holds promise for revolutionizing industries, from aerospace to healthcare, by delivering unparalleled accuracy and efficiency in component production. As CNC machines continue to evolve, their impact on shaping modern manufacturing processes will undoubtedly drive advancements and efficiencies across diverse sectors.

See Also

Exploring the Core Concepts of CNC Precision Manufacturing

Delving into CNC Machining Fundamentals for Component Production

Investigating CNC Machinery and Precision Engineering in Electronics Production

CNC in Production: Understanding the Progress and Uses of CNC Tech

Discovering CNC Machining: Precision Production and Metal Carving

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com