Manual vs CNC Machining: Discovering Their Strengths

Machining processes are essential in manufacturing, transforming materials into precise components. Understanding the differences between Manual Machining and CNC is key to making informed decisions. Manual Machining, which depends on skilled technicians to operate machines, is advantageous for small-scale projects. On the other hand, CNC machining leverages computer programming to deliver high precision and efficiency, particularly beneficial in mass production. The advantages of each method cater to diverse industry needs. By comprehending these distinctions, you can select the most suitable approach for your specific requirements.

Understanding Machining Processes

What is Manual Machining?

Definition and Overview

Manual machining involves the use of hand-operated machinery to shape and form materials into desired components. You rely on skilled technicians to operate these machines, which include lathes, milling machines, and drill presses. Each machine requires precise manual control to achieve the desired outcome. This process allows for a high degree of flexibility, as you can make adjustments on the fly based on the operator's expertise and judgment.

Historical Context and Evolution

Manual machining has a rich history that dates back to the early days of the Industrial Revolution. During this period, craftsmen used basic tools to create intricate parts for machinery and equipment. Over time, manual machining evolved with the introduction of more advanced tools and techniques. The development of powered machinery in the 19th century marked a significant advancement, allowing for increased productivity and precision. Despite the rise of automated technologies, manual machining remains a valuable skill, especially for custom and small-scale projects.

What is CNC Machining?

Definition and Overview

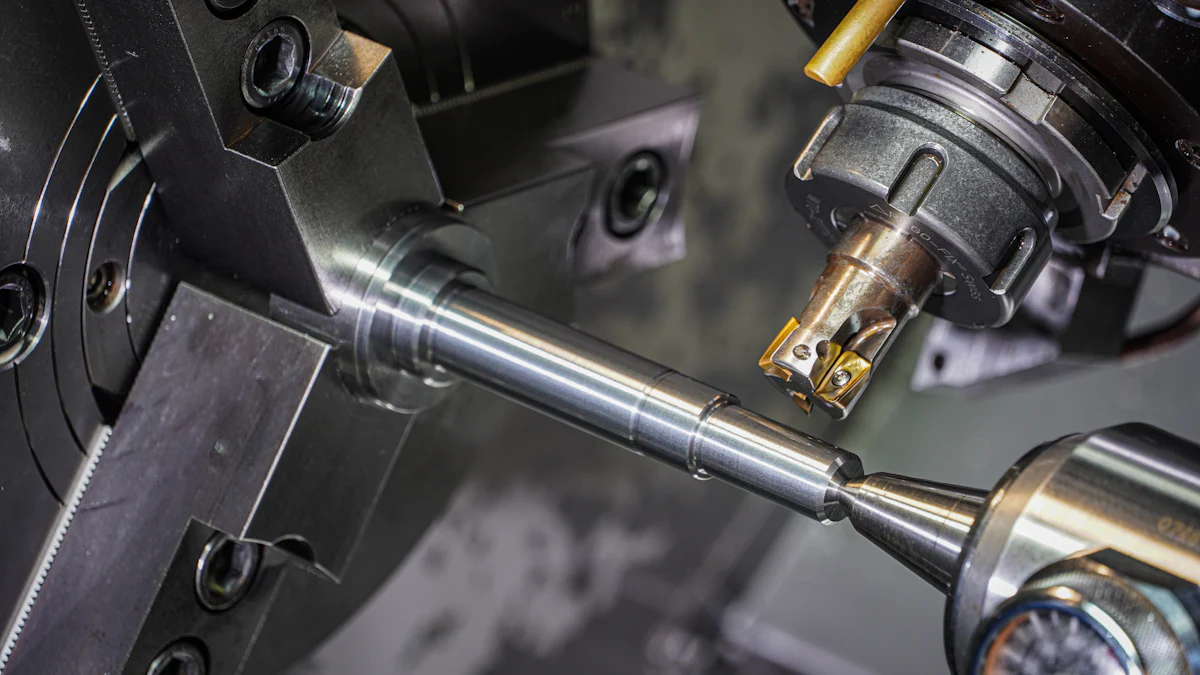

CNC (Computer Numerical Control) machining represents a significant leap forward in manufacturing technology. This process uses computer software to control machine tools, enabling you to produce complex and precise components with minimal human intervention. CNC machines follow programmed instructions to perform tasks such as cutting, drilling, and milling. This automation ensures consistent quality and accuracy, making CNC machining ideal for high-volume production and intricate designs.

Technological Advancements and Evolution

The introduction of CNC technology in the mid-20th century revolutionized the machining industry. By automating processes, CNC machines enabled complex operations that were previously impossible with manual controls. Over nearly 70 years, CNC machining has grown into a highly precise and flexible fabrication method. The utilization of digital designs and computerized blueprints transformed the manufacturing industry, allowing for extreme accuracy and efficiency. Today, CNC machines continue to evolve, incorporating advanced features like multi-axis capabilities and real-time monitoring to further enhance their performance.

Comparing Manual and CNC Machining

Advantages of Manual Machining

Flexibility and Adaptability

Manual machining offers you a high degree of flexibility. Skilled technicians can make on-the-spot adjustments, allowing for creative problem-solving and customization. This adaptability proves beneficial when working on unique or intricate designs that require a personal touch. You can easily modify the process to accommodate changes, making manual machining ideal for projects where precision isn't the sole focus.

Cost-Effectiveness for Small Projects

For small-scale projects, manual machining often presents a more cost-effective solution. The initial investment in manual equipment is lower compared to CNC machines. You can achieve satisfactory results without the need for expensive technology. This makes manual machining a practical choice for startups or businesses with limited budgets. You can manage costs effectively while still delivering quality products.

Advantages of CNC Machining

Precision and Accuracy

CNC machining excels in delivering unparalleled precision and accuracy. The computer-controlled process ensures that each component meets exact specifications. You benefit from consistent quality, especially in high-volume production. CNC machines can achieve microscopic precision, making them indispensable for industries where accuracy is paramount. You can rely on CNC machining for intricate designs that demand meticulous attention to detail.

Efficiency and Speed

When it comes to efficiency and speed, CNC machining stands out. The automation of processes allows for continuous operation, reducing downtime and increasing productivity. You can produce large quantities of components quickly, meeting tight deadlines with ease. CNC machines operate at high speeds, enabling you to complete projects faster than manual methods. This efficiency is particularly advantageous in mass production scenarios.

Disadvantages of Manual Machining

Limited Precision

While manual machining offers flexibility, it falls short in precision. Achieving high levels of accuracy requires exceptional skill and experience. You may encounter variations in quality due to human error. For projects demanding exact specifications, manual machining might not meet your needs. The reliance on manual control limits the precision achievable compared to CNC machining.

Labor-Intensive Process

Manual machining demands significant labor input. Skilled technicians must operate each machine, requiring constant attention and effort. You may find this process time-consuming, especially for complex tasks. The labor-intensive nature of manual machining can lead to increased production times and costs. In contrast, CNC machining allows one operator to oversee multiple machines, enhancing efficiency.

Disadvantages of CNC Machining

High Initial Investment

When you consider CNC machining, one of the first challenges you encounter is the high initial investment. Purchasing CNC machines requires a significant financial commitment. These machines come with advanced technology and features, which contribute to their cost. You need to factor in not only the price of the machine itself but also the expenses related to installation and setup. This can be a barrier for small businesses or startups with limited budgets. While CNC machining offers long-term benefits, the upfront costs can be daunting.

Complexity in Programming

Another hurdle you face with CNC machining is the complexity in programming. Operating CNC machines demands a solid understanding of computer programming and software. You must create precise digital blueprints and instructions for the machine to follow. This requires skilled personnel who are proficient in programming languages and software used in CNC operations. The learning curve can be steep, and mistakes in programming can lead to costly errors. You need to invest time and resources in training to ensure that your team can effectively manage CNC machines.

Specific Attributes Comparison

Accuracy and Precision

Manual Machining Accuracy

In manual machining, accuracy depends heavily on the skill of the operator. You must rely on your expertise to achieve the desired precision. This process involves careful measurements and adjustments, which can lead to variations in quality. While manual machining allows for flexibility, it may not always meet the stringent accuracy requirements of certain industries. You need to invest time in training and practice to enhance your skills and improve the accuracy of your work.

CNC Machining Precision

CNC machining excels in delivering high precision. The computer-controlled process ensures that each component meets exact specifications. You benefit from consistent quality, especially in high-volume production. CNC machines can achieve microscopic precision, making them indispensable for industries where accuracy is paramount. You can rely on CNC machining for intricate designs that demand meticulous attention to detail. The automation of processes reduces the risk of human error, enhancing the overall precision of your projects.

Complexity and Versatility

Handling Complex Designs

When it comes to handling complex designs, CNC machining stands out. You can produce intricate components with ease, thanks to the advanced capabilities of CNC machines. These machines follow programmed instructions to perform tasks such as cutting, drilling, and milling. This automation allows you to create complex shapes and designs that are often impossible to achieve with manual controls. You can rely on CNC machining for projects that require high levels of complexity and precision.

Versatility in Applications

Both manual and CNC machining offer versatility in applications. Manual machining provides flexibility, allowing you to make on-the-spot adjustments and modifications. This adaptability proves beneficial when working on unique or intricate designs. On the other hand, CNC machining offers versatility through its ability to handle a wide range of materials and designs. You can use CNC machines for various applications, from mass production to custom components. The versatility of each method caters to diverse industry needs, allowing you to choose the most suitable approach for your specific requirements.

Cost Considerations

Initial Costs

When considering initial costs, manual machining often presents a more cost-effective solution. The investment in manual equipment is lower compared to CNC machines. You can achieve satisfactory results without the need for expensive technology. This makes manual machining a practical choice for startups or businesses with limited budgets. However, CNC machining requires a significant financial commitment. Purchasing CNC machines involves high initial investment, including expenses related to installation and setup. You need to weigh the benefits against the costs to determine the best option for your business.

Long-term Cost Efficiency

In terms of long-term cost efficiency, CNC machining offers several advantages. The automation of processes reduces labor costs and increases productivity. You can produce large quantities of components quickly, meeting tight deadlines with ease. CNC machines operate at high speeds, enabling you to complete projects faster than manual methods. This efficiency is particularly advantageous in mass production scenarios. While the initial investment in CNC machines is high, the long-term benefits can outweigh the costs, making it a cost-effective solution for high-volume production.

Applications and Decision-Making Factors

Common Applications of Manual Machining

Prototyping and Custom Parts

Manual Machining shines in prototyping and creating custom parts. You can easily make adjustments and modifications during the machining process. This flexibility allows you to experiment with different designs and materials. When you need a unique component, Manual Machining provides the adaptability required to meet specific needs. Skilled technicians can craft parts that fit precise requirements, making it ideal for projects where customization is key.

Repair and Maintenance Work

In repair and maintenance work, Manual Machining proves invaluable. You can quickly address issues with existing machinery by crafting replacement parts on-site. This capability reduces downtime and ensures that equipment remains operational. Manual Machining allows you to respond to unexpected challenges with agility. The hands-on approach enables you to tailor solutions to the specific problem at hand, ensuring that repairs are both effective and efficient.

Common Applications of CNC Machining

Mass Production

CNC Machining excels in mass production scenarios. You can produce large quantities of components with consistent quality and precision. The automation of CNC processes ensures that each part meets exact specifications, reducing the risk of errors. This makes CNC Machining ideal for industries that require high-volume production, such as automotive and electronics. You benefit from increased efficiency and reduced production times, allowing you to meet tight deadlines with ease.

High Precision Components

When you need high precision components, CNC Machining is the go-to choice. The computer-controlled process delivers unparalleled accuracy, achieving tolerances within a few thousandths of an inch. This precision is crucial in industries like aerospace and medical devices, where even the smallest deviation can have significant consequences. CNC Machining eliminates human error, ensuring that each component meets the highest standards of quality and reliability.

Factors to Consider When Choosing

Project Scale and Budget

When deciding between Manual Machining and CNC, consider the scale of your project and your budget. Manual Machining often presents a more cost-effective solution for small-scale projects. The initial investment in manual equipment is lower, making it accessible for startups or businesses with limited funds. However, for larger projects, the efficiency and speed of CNC Machining may justify the higher initial costs. You need to weigh the benefits against the expenses to determine the best fit for your needs.

Required Precision and Complexity

The required precision and complexity of your project also influence your choice. Manual Machining offers flexibility and adaptability, making it suitable for projects that require creative problem-solving and customization. However, if your project demands high precision and intricate designs, CNC Machining is the better option. The automation and accuracy of CNC processes ensure that each component meets exact specifications, reducing the risk of errors and enhancing the overall quality of your work.

Understanding the strengths of manual and CNC machining helps you make informed decisions. Manual machining offers flexibility and cost-effectiveness for small projects. CNC machining excels in precision and efficiency, ideal for high-volume production. When choosing a machining process, consider your project's scale, budget, and complexity. Each method has unique advantages that cater to different needs. By evaluating these factors, you can select the most suitable approach. Remember, the right choice depends on your specific requirements and circumstances.

See Also

Discovering CNC Machining Solutions for Precise Manufacturing

Comprehending Key Steps in CNC Precision Machining

Setting Apart Precision Machining vs. General CNC: An In-Depth Overview

CNC in Production: Exploring Innovations and Uses of CNC Tech

Investigating CNC Machining: Precise Production and Metal Carving

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com