Understanding Material Properties and Their Impact on CNC Application Material

Material properties play a critical role in CNC machining. They determine how a material interacts with tools and influence the quality of the final product. For example, harder materials like metals demand precise tools to achieve smooth finishes, while softer materials, such as plastics, allow for easier machining. Properties like thermal conductivity and melting point also affect the process. High melting points require advanced tools, while low thermal conductivity can lead to uneven temperatures, impacting surface precision. By understanding these properties, you can select the right CNC application material to optimize manufacturing outcomes.

Key Takeaways

Material traits like strength and hardness impact cutting speed and finish. Pick materials carefully for long-lasting and accurate results.

Knowing machinability helps pick the best tools and methods. Easy-to-machine materials, like aluminum, boost work speed and save money.

Think about the environment when picking materials. Use ones that handle heat, water, and chemicals for steady performance.

Key Material Properties for CNC Application Material

Strength and Hardness

Strength and hardness are critical mechanical properties that influence how materials behave during CNC machining. Strength measures a material's ability to resist external forces, while hardness reflects its resistance to localized deformation. Hard materials, such as titanium and carbon steel, require specialized cutting tools due to their wear resistance. Softer materials, like plastics, are easier to machine but may smear if not handled properly. These properties directly impact the tooling, machining speed, and surface finish of CNC machined parts. For high precision parts, selecting materials with appropriate strength and hardness ensures durability and dimensional accuracy.

Machinability

Machinability determines how easily a material can be cut, shaped, or finished during the CNC process. Factors like hardness, toughness, and thermal conductivity play a role in machinability. Materials with high machinability, such as aluminum, allow for faster cutting speeds and extended tool life. On the other hand, materials with poor machinability, like stainless steel, may require slower processes and specialized tooling. Effective material selection based on machinability enhances productivity and reduces manufacturing costs. Proper tool geometry and cooling methods also improve machining efficiency and precision.

Thermal and Chemical Resistance

Thermal and chemical resistance are essential for materials used in demanding environments. High thermal resistance prevents deformation under heat, while chemical resistance ensures stability in corrosive conditions. For example, titanium and PEEK are ideal for CNC machining applications in aerospace and medical industries due to their ability to withstand extreme temperatures and chemical exposure. These properties make them suitable for precision manufacturing processes where durability and reliability are paramount.

Density and Weight

The density and weight of a material affect its performance and machinability. Lightweight materials, such as aluminum and magnesium, are preferred for applications requiring high strength-to-weight ratios. Heavier materials, like carbon steel, provide durability but may require more robust machining setups. Material selection based on density ensures optimal performance and efficiency in the manufacturing process. For high precision parts, lightweight materials often enhance functionality without compromising strength.

Impact of Material Properties on CNC Machining

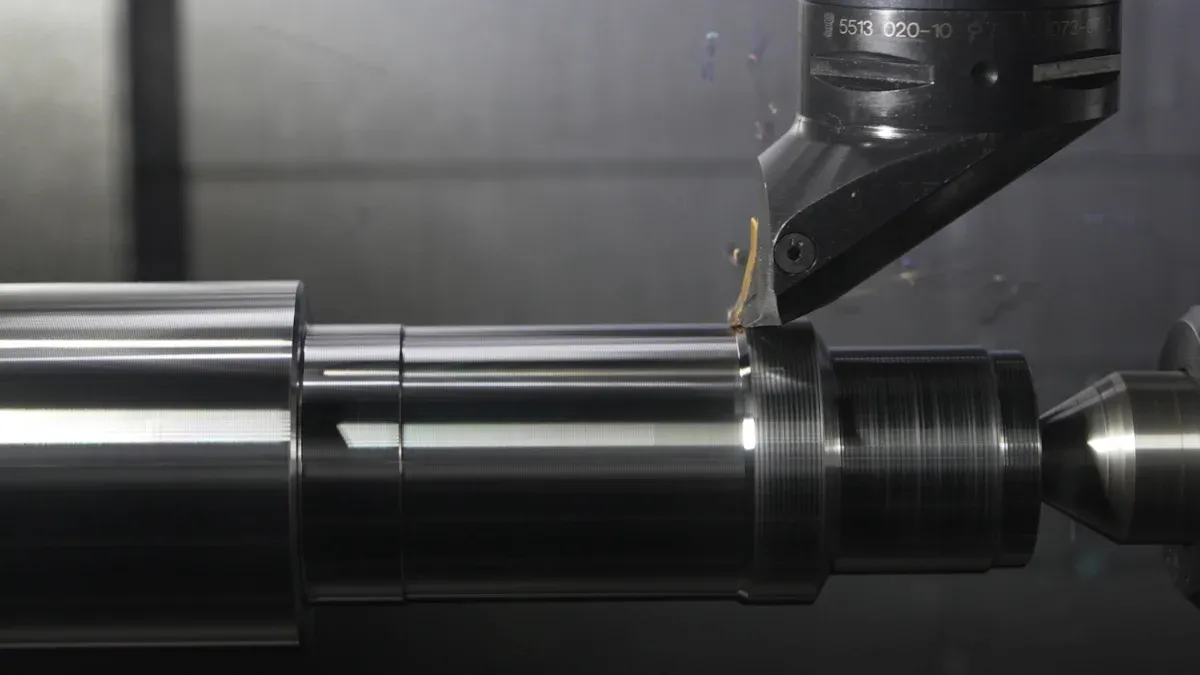

Tooling and Wear

Material properties significantly influence tooling wear during CNC machining. Softer materials like aluminum are easier to machine and cause less wear on cutting tools. In contrast, tougher materials such as titanium or carbon fiber can damage tool edges, requiring more robust tooling systems. Hardness, toughness, and ductility dictate the choice of tools and machining parameters. For example:

Hard materials demand precise tools and slower speeds to prevent breakage.

Tougher tools are ideal for roughing operations to withstand greater stress.

Effective coolant application reduces heat buildup and prevents recutting chips.

By understanding these properties, you can optimize machining strategies and extend tool life, reducing costs and improving efficiency.

Machining Efficiency and Speed

Material properties like hardness and ductility directly affect machining efficiency and speed. Harder materials require slower speeds to achieve desired finishes, while ductile materials allow faster shaping without breaking. For instance:

High machinability materials, such as aluminum, enhance speed and reduce tool wear.

Poor machinability materials, like stainless steel, demand slower processes and specialized tools.

Thermal conductivity also plays a role. Materials that dissipate heat effectively improve tool life and machining efficiency. Selecting the right material ensures a balance between speed and precision in the manufacturing process.

Surface Finish and Dimensional Accuracy

Achieving a high-quality surface finish and dimensional accuracy depends on material properties. Harder materials require precise tools and conditions to avoid poor finishes. Ductile materials, on the other hand, produce smoother finishes due to finer chip removal. Techniques like using coolants, advanced cutting strategies, and post-machining processes like grinding can further enhance surface quality. Proper material selection ensures high precision parts meet design specifications.

Examples of CNC Application Materials

Aluminum: Lightweight and machinable

Aluminum offers excellent machinability and moderate strength. Its lightweight nature makes it ideal for automotive and aerospace applications.

Steel: Durable and versatile

Steel provides high strength and heat resistance. It suits applications requiring durability, such as medical devices and marine components.

Plastics: Flexible and cost-effective

Plastics like ABS are versatile and easy to machine. They are commonly used for prototypes and low-stress parts due to their low cost and flexibility.

Practical Considerations for Selecting CNC Application Material

Balancing Cost and Performance

When selecting a material for CNC machining, balancing cost and performance is essential. You must evaluate the project budget to ensure the material fits within financial constraints. At the same time, the material must meet performance requirements, such as strength, durability, and machinability. Consider the following factors:

Material properties determine suitability for specific applications.

Product design influences material choice based on functional needs.

Cost analysis ensures materials remain within budget.

Scalability is crucial for mass production.

Regulatory compliance and sustainability impact material selection.

For cost-effective options that don’t compromise performance, materials like high-density polyethylene (HDPE), polyethylene terephthalate (PET), and polyvinyl chloride (PVC) are excellent choices. These materials offer durability, machinability, and affordability, making them ideal for various CNC machining applications.

Meeting Design and Functional Requirements

Material properties must align with the design and functional requirements of your project. For instance, high strength materials like steel or titanium are ideal for applications requiring durability, while plastics like nylon or ABS are better suited for lightweight, flexible designs. To ensure compatibility:

Select materials based on properties like machinability, thermal stability, and strength.

Match the material to the machining tools and processes.

Consider the material’s performance during machining to achieve high precision and efficiency.

Materials such as carbon fiber reinforced polymers (CFRP) and aluminum are excellent for precision manufacturing due to their strength-to-weight ratio and machinability. Early consideration of these factors ensures your CNC machined parts meet both functional and aesthetic goals.

Accounting for Environmental and Operational Conditions

Environmental and operational conditions play a significant role in material selection. Materials must withstand factors like temperature, moisture, and chemical exposure. For outdoor applications, choose materials resistant to extreme weather and corrosion. Sustainable materials can also reduce environmental impact. Examples of materials suited for harsh conditions include:

Material | Key Properties | Applications |

|---|---|---|

Titanium | High strength-to-weight ratio, corrosion resistance, strong heat conductivity | Aerospace, military, medical |

Magnesium | Lightweight, superb thermal characteristics | High-temperature parts, fuel-efficient vehicles |

Acetal (POM) | Tough, moisture and impact resistant, excellent fatigue resistance | Precision components like bearings and gears |

Nylon | Strong, durable, impact-resistant, excellent lubricating properties | Sprockets, bearings, sliding surfaces |

UHMW-PE | High toughness, abrasion and wear resistance, endurance | Sliding surfaces in bearings, gears, rollers |

By considering these factors, you can select materials that perform reliably under specific environmental and operational conditions, ensuring the longevity and functionality of your CNC machined parts.

Material properties play a vital role in every stage of the CNC machining process. Understanding characteristics like hardness, toughness, and ductility ensures you select the right materials for your project. Aligning material selection with application needs improves precision, efficiency, and manufacturing outcomes. This knowledge empowers you to achieve reliable and high-quality results.

FAQ

What is the most machinable material for CNC machining?

Aluminum is highly machinable. It allows faster cutting speeds, reduces tool wear, and produces excellent surface finishes, making it ideal for many CNC applications.

How do material properties affect CNC tool selection?

Material hardness and toughness determine tool type. Harder materials need durable tools, while softer ones require sharp edges to prevent smearing or deformation during machining.

Can lightweight materials maintain strength in CNC applications?

Yes, materials like aluminum and carbon fiber offer high strength-to-weight ratios. These materials provide durability without adding unnecessary weight, making them suitable for aerospace and automotive industries.

See Also

Grasping Material Needs for CNC Precision Machining

Excelling in CNC Machining: Tolerances, Prototyping, and Materials

Become Proficient in CNC Machining: Technical Drawings and Materials

Comprehending Key Processes in CNC Precision Machining

Learning CNC Machining Fundamentals for Component Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com