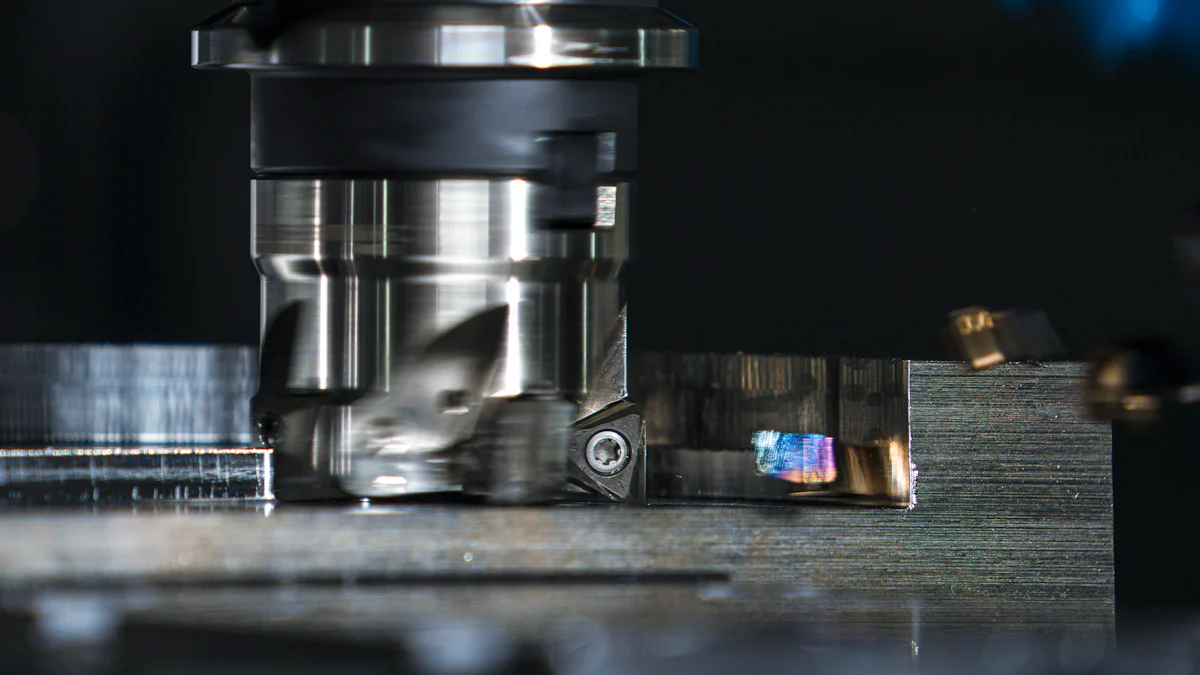

Achieving Micro-Level Precision with CNC Machining

Achieving micro-level precision in CNC machining is essential for modern manufacturing. You rely on this technology to produce highly complex parts with unmatched accuracy. Industries like aerospace, healthcare, and electronics demand 0.001mm precision to meet strict design requirements. This level of accuracy ensures consistent quality, reduces production delays, and enhances product reliability. For example, medical devices require precise machining to function safely, while consumer electronics depend on intricate micro-scale parts for optimal performance. By maintaining tight tolerances, precision CNC machining guarantees that every part fits perfectly, improving efficiency and reducing the need for adjustments.

Key Takeaways

Tiny precision in CNC machining is important for fields like planes and medicine, making sure parts fit exact designs.

Picking the right materials and knowing their traits can improve accuracy and make tools last longer.

Checking and fixing machines often keeps them precise; use tools like micrometers and ballbar tests to align them well.

Watching machines in real-time can spot mistakes fast, so fixes can be made right away to stay accurate.

Using new methods like multi-axis machining and mixed manufacturing can speed up work and make it more exact.

Challenges in Precision CNC Machining

Precision CNC machining comes with its own set of challenges. These challenges can arise from the materials you work with, the limitations of the machine tools, and the environmental conditions surrounding the machining process. Understanding these factors helps you address potential issues and maintain the highest levels of accuracy.

Material Challenges

The properties of the material you choose significantly impact the precision of CNC machining. Harder materials, such as certain metals, allow for tighter tolerances but can increase tool wear. Thermal expansion is another factor to consider. For instance, a ten-inch aluminum bar can expand or contract with just a ten-degree Fahrenheit temperature change, affecting dimensional stability. Materials with poor machinability make cutting and shaping more difficult, reducing accuracy and surface quality. Additionally, unique material characteristics influence cutting forces and tool performance, which can lead to burrs or overcutting on parts. By selecting the right material and understanding its behavior, you can minimize these issues and achieve better results.

Machine Tool Limitations

CNC machines have inherent limitations that can affect precision. Tool size restricts the ability to produce micro-scale parts, as smaller tools may be impractical or expensive. Tool shape often requires multiple machines to handle complex designs, increasing costs and setup time. Precise alignment of tools and fixtures is critical. Even minor errors in alignment can lead to significant inaccuracies in the final product. Furthermore, the rigidity, speed, and thermal stability of the machine play a crucial role in maintaining accuracy. High-performance machines help mitigate these limitations, but they come with significant purchase and repair costs.

Environmental Factors

Environmental conditions directly influence the precision of CNC machining. Temperature fluctuations can cause thermal expansion in both the machine and the material, leading to dimensional inaccuracies. Humidity can alter material properties and affect machine calibration. For example, airborne contaminants and ambient vibrations can disrupt the machining process, reducing accuracy. A controlled environment with stable temperature and humidity levels ensures consistent machining tolerances. By addressing these environmental factors, you can maintain the reliability of your CNC operations.

Key Factors in High-Precision CNC Machining

Achieving 0.001mm precision in CNC machining requires attention to several critical factors. By focusing on machine selection, tool maintenance, and cutting parameter optimization, you can ensure consistent accuracy and superior results.

Machine Selection and Calibration

Choosing the right machine is the foundation of high-precision CNC machining. You should prioritize machines that meet your design and tolerance requirements. Consider factors like the complexity of machining operations, repeatability, and compatibility with calibration systems. Regular calibration is equally important to maintain accuracy. Use tools like micrometers, machinist’s levels, and ballbar testing equipment to ensure precise alignment.

Environmental conditions also play a significant role. Temperature fluctuations, humidity, and vibrations can disrupt calibration. Maintaining a controlled environment minimizes these risks. Additionally, qualified calibration technicians are essential for accurate setup and adjustments. Implementing a preventive maintenance schedule for calibration tools, including cleaning and inspection, further enhances precision.

Tool Selection and Maintenance

The condition of your tools directly impacts the quality of your parts. Regular maintenance practices, such as cleaning, lubrication, and sharpening, keep micro-cutting tools in optimal condition. Dull tools or improper alignment can lead to inaccuracies and poor surface finishes. You should also monitor cutting speeds and replace worn tools promptly to maintain 0.001mm precision.

Using the correct coolant and storing tools properly prevents corrosion and extends their lifespan. Predictive maintenance, which uses data to determine the best time for upkeep, can reduce downtime and improve efficiency. By maintaining your tools, you ensure consistent machining accuracy and extend the life of your high-precision equipment.

Cutting Parameters Optimization

Optimizing cutting parameters is crucial for achieving tight tolerances. Adjusting cutting speeds and feed rates based on material hardness helps balance efficiency and tool life. For example, harder materials require slower speeds to maintain accuracy. Always refer to tool manufacturer recommendations for cutting speeds and start with suggested feed rates.

During prototype machining, you can fine-tune these parameters to achieve the desired results. This approach not only improves surface finish but also extends tool longevity. By carefully managing cutting parameters, you enhance the overall precision of your CNC operations.

Measurement Tools and Techniques

Accurate measurement tools and techniques are essential for achieving micro-level precision in CNC machining. These tools help you monitor tolerances, ensure proper calibration, and verify that finished parts meet exact specifications.

You can rely on precision instruments like calipers and micrometers for accurate calibration. These tools measure dimensions with exceptional accuracy, ensuring your machine operates within the required tolerances. A QC20 ballbar is another valuable tool. It detects even the smallest variations in radius, helping you identify and correct alignment issues in your CNC machine.

During machining, in-process measurement tools like Renishaw OMP400 probes allow you to monitor tolerances in real time. These probes provide immediate feedback, enabling you to make adjustments as needed. This approach minimizes errors and ensures consistent quality throughout the machining process.

Post-machining inspection is equally important. Coordinate Measuring Machines (CMMs) and laser measurement tools are ideal for verifying that finished parts meet design specifications. These tools provide detailed data on dimensions, surface finishes, and geometric accuracy, giving you confidence in the quality of your work.

Advanced techniques like adaptive control systems further enhance precision. These systems automatically adjust machining parameters in real time, reducing the risk of human error. Multi-axis machining, such as 5-axis CNC milling, also plays a crucial role. It allows you to create complex geometries in a single setup, improving accuracy and reducing the need for multiple adjustments.

By using these advanced tools and techniques, you can achieve the highest levels of precision in your CNC machining operations. Accurate measurements ensure that every part meets your exact requirements, enhancing both quality and reliability.

Methods to Achieve Micro-Level Precision

Machine Setup and Alignment

Proper machine setup and alignment form the backbone of achieving 0.001mm precision in cnc machining. You must ensure that every component of the cnc machine is perfectly aligned to prevent errors. Using laser alignment systems and ball-bar testing can help eliminate misalignment issues. These tools detect even the smallest deviations, allowing you to make precise adjustments. Installing machines on vibration-dampened foundations further enhances stability, while laser leveling systems ensure accurate setup.

Regular maintenance is equally important. Inspections and servicing of machine components prevent wear and maintain performance. Accurate tool setup also plays a critical role. Misaligned tools can cause deflection and vibration, compromising accuracy. By focusing on these methods, you can achieve the precision required for cutting-edge micro-manufacturing.

Method | Description |

|---|---|

Multi-axis machining | Enables complex geometries in a single setup, enhancing precision and reducing errors. |

Adaptive control systems | Automatically adjust machining parameters in real-time to maintain tight tolerances. |

Regular maintenance | Inspections and servicing of components prevent wear and enhance performance. |

Accurate tool setup | Ensures tools are aligned and calibrated to minimize deflection and vibration. |

Environmental control | Maintains stable temperature and humidity to prevent inaccuracies. |

Monitoring systems | Track parameters in real-time for automatic adjustments to maintain tolerances. |

Material Preparation and Stability

Material preparation is a crucial step in precision cnc machining. Thermal dynamics can cause dimensional changes and distortions in both the workpiece and the machine tool. These changes may lead to warpage or tool deflection, which can compromise surface finish and dimensional accuracy. To counter these effects, you should use thermal stabilization methods and carefully select machining parameters.

Different materials behave differently during machining. For instance, metals like aluminum expand with temperature changes, while harder materials may require slower cutting speeds. Selecting tools and cutting parameters based on material characteristics ensures machining quality. By preparing materials properly, you can maintain the stability needed for 0.001mm precision.

Toolpath Optimization

Optimizing the toolpath is essential for achieving micro-manufacturing precision. A well-designed toolpath minimizes unnecessary movements, reducing machining time and improving accuracy. You should analyze the design of your parts and create a toolpath that follows the most efficient route. This approach reduces tool wear and enhances surface finish.

Advanced software can help you simulate toolpaths before machining begins. These simulations allow you to identify potential issues and make adjustments. Real-time monitoring systems also play a role in toolpath optimization. They track parameters during machining and make automatic adjustments to maintain tolerances. By optimizing the toolpath, you can achieve the precision required for micro-manufacturing techniques.

Real-Time Monitoring and Adjustments

Real-time monitoring and adjustments play a vital role in achieving micro-level precision in CNC machining. Advanced CNC machines now feature integrated monitoring systems that detect deviations during operations and adjust parameters automatically. These systems ensure consistent quality by modifying cutting conditions based on tool wear. This approach helps you maintain tight tolerances and avoid costly errors.

Continuous monitoring offers several benefits:

Maintaining Dimensional Accuracy and Surface Finish: Immediate adjustments prevent defects and reduce the risk of scrap parts.

Preventing Tool Breakage and Premature Wear: Monitoring cutting loads helps you identify excessive wear, allowing timely tool replacements.

Optimizing Machining Efficiency: Fine-tuning parameters during operations enhances production speed and minimizes costs.

Modern monitoring systems provide you with tools to track and improve machining processes. The table below highlights some of the most advanced features available today:

Feature | Description |

|---|---|

Real-Time Dashboards | Offers immediate insights into job performance with color-coded indicators. |

Operator View Tablets | Allows operators to manage machine data directly at the machine using a touchscreen interface. |

Alerts and Notifications | Sends customizable alerts via text or email for issues like downtime or delays. |

OEE Performance Reporting | Automates reporting on Overall Equipment Effectiveness (OEE) to identify operational inefficiencies. |

Quality Tracking and Reporting | Tracks quality data in real time, eliminating the need for manual records. |

Machine Utilization Reporting | Monitors machine usage and compares it to industry benchmarks. |

Job Setup/Changeover Tracking | Tracks setup times to reduce lost production time. |

Detailed Machine Production Analytics | Analyzes historical machine data to uncover performance issues. |

Detailed Part Number and Job Analytics | Provides comprehensive reports on cycle times, performance, and reject reasons for each part operation. |

By leveraging these systems, you can gain valuable insights into your machining processes. Real-time monitoring not only ensures precision but also improves efficiency and reduces downtime. These tools empower you to maintain the highest standards in CNC machining, meeting even the most demanding requirements.

Quality Control in Precision CNC Machining

Inspection Techniques

Inspection techniques ensure that every part meets your design specifications and maintains the required accuracy. These methods help you verify dimensions, surface finishes, and geometric tolerances. Coordinate Measuring Machines (CMMs) are among the most reliable tools for this purpose. They provide precise, automated measurements for complex geometries and tight tolerances. Using tactile or non-contact probes, CMMs validate dimensional accuracy and generate detailed reports. This ensures that your parts conform to both dimensional and geometric standards.

Geometric tolerancing is another critical aspect of inspection. It applies precise tolerances to features like flatness and roundness. By combining CMMs with GD&T (Geometric Dimensioning and Tolerancing) principles, you can achieve exceptional accuracy when evaluating complex shapes. These tools and techniques ensure that your precision CNC machining process consistently delivers high-quality results.

Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) plays a vital role in assessing the structural integrity of CNC machined parts without causing damage. This method ensures reliability and soundness while preserving the material. Ultrasonic Testing, for example, uses high-frequency sound waves to detect internal flaws. X-ray and Magnetic Particle Inspection are also effective for identifying surface and sub-surface defects.

These techniques rely on physical principles like electromagnetic fields or ultrasonic waves to detect inclusions or discontinuities. NDT verifies the accuracy and conformity of your machining process to design specifications. By incorporating NDT into your quality control process, you can ensure that every part meets the highest standards of reliability.

Statistical Process Control (SPC)

Statistical Process Control (SPC) helps you maintain precision during CNC machining by analyzing production data. This method allows you to monitor real-time data and identify anomalies that could affect part quality. By observing control charts and investigating deviations, you can implement corrective actions to stabilize the machining process.

SPC minimizes the chances of producing parts that are out of tolerance. This is especially critical when dealing with multiple characteristics requiring 0.001mm precision. By using SPC, you enhance the quality and reliability of your high-precision CNC machining operations while reducing costs. This approach ensures that your final products consistently meet design requirements.

Advanced Technologies in CNC Machining

High-Speed Machining (HSM)

High-Speed Machining (HSM) revolutionizes the way you achieve micro-level precision in cnc machining. This advanced technique uses higher spindle speeds and feed rates to enhance efficiency and accuracy. By adopting HSM, you can significantly reduce cycle times while maintaining exceptional quality.

The benefits of HSM extend beyond speed. It ensures excellent dimensional precision, making it ideal for producing intricate parts with tight tolerances. You can also eliminate unnecessary steps, such as post-machining polishing, by achieving superior surface finishes directly during the machining process. The table below highlights the key advantages of HSM:

Benefit | Description |

|---|---|

High Metal Removal Rate (MRR) | Allows for faster machining processes and reduced cycle time. |

Excellent Dimensional Precision & Accuracy | Ensures that parts meet tight tolerances and specifications. |

Ability for 3D Complex Parts | Facilitates the production of intricate designs with high precision. |

Elimination of Unnecessary Steps | Reduces the need for additional processes like polishing. |

By leveraging HSM, you can enhance productivity and achieve the precision required for modern manufacturing.

Multi-Axis CNC Machining

Multi-axis CNC machining takes precision to the next level by enabling the creation of complex parts in a single setup. This technology allows you to machine intricate geometries with fewer errors and higher accuracy.

Multi-axis machining minimizes the need for multiple setups, reducing accumulated errors and improving geometric precision.

It maintains optimal cutting positions, which reduces tool wear and ensures consistent results.

Combining various machining processes into one setup streamlines production and enhances accuracy for complex parts.

With multi-axis CNC machining, you can achieve superior precision while simplifying your workflow. This capability makes it an essential tool for industries requiring intricate designs and tight tolerances.

Automation and AI Integration

Automation and AI integration are transforming cnc machining by enhancing precision and efficiency. Robots now handle repetitive tasks with unmatched accuracy, reducing manual errors and improving product quality. These advancements also boost operator safety by minimizing human intervention in hazardous processes.

AI-driven systems optimize machining processes by predicting tool wear and adjusting parameters in real time. This reduces waste and ensures consistent results. Modern CNC machines equipped with automation and robotics further enhance efficiency by reducing downtime and maintaining tight tolerances.

AI-powered tools also learn from data, enabling them to adapt and refine tool paths for better performance. By integrating automation and AI, you can streamline production workflows, improve precision, and meet the demands of complex manufacturing tasks.

Additive and Hybrid Manufacturing

Additive and hybrid manufacturing are transforming the way you achieve precision in CNC machining. These advanced techniques combine the strengths of additive manufacturing and traditional CNC machining to deliver exceptional results. By leveraging these methods, you can create intricate parts with unmatched accuracy and efficiency.

Hybrid manufacturing begins with metal additive manufacturing. This process builds complex, near-net-shape parts layer by layer. Once the base structure is complete, CNC machining refines the part to achieve precise dimensions and a superior surface finish. This combination allows you to produce lightweight, intricate components that meet strict mechanical and aesthetic standards. Industries like aerospace rely on this approach to manufacture parts that perform under extreme conditions.

Tip: Hybrid manufacturing is ideal for producing parts with complex geometries that would be difficult or impossible to machine using traditional methods alone.

The integration of additive and CNC machining offers several advantages:

Optimized Material Usage: Additive manufacturing minimizes waste by using only the material needed to build the part.

Accelerated Production Timelines: Combining both methods reduces the time required to create complex parts.

Enhanced Precision: CNC machining ensures that the final product meets tight tolerances and design specifications.

For example, you can use hybrid manufacturing to produce aerospace components with intricate internal structures. Additive manufacturing creates the complex framework, while CNC machining ensures the part fits perfectly and performs reliably. This approach not only saves time but also reduces material costs.

By adopting additive and hybrid manufacturing, you can push the boundaries of what’s possible in CNC machining. These technologies enable you to meet the growing demand for precision and innovation in modern manufacturing.

Micro-level precision in CNC machining is essential for producing high-quality parts that meet modern engineering standards. You face challenges like maintaining tight tolerances, managing thermal effects, and ensuring efficient chip evacuation. However, advanced methods and technologies, such as multi-axis machining and adaptive control systems, help you overcome these obstacles. These innovations enhance accuracy, reduce errors, and streamline production.

The evolution of CNC machining continues to push boundaries. Trends like automation, micromachining, and cryogenic machining improve efficiency and precision. By adopting these advancements, you can meet growing demands and maintain a competitive edge in manufacturing.

FAQ

What is the importance of precision in CNC machining?

Precision ensures that parts meet exact specifications, improving their quality and performance. It reduces errors, minimizes waste, and guarantees reliability in industries like aerospace and healthcare. Achieving micro-level precision in CNC machining helps you produce components that fit perfectly and function as intended.

How can you maintain tight tolerances in CNC machining?

You can maintain tight tolerances by selecting the right machine, calibrating it regularly, and optimizing cutting parameters. Proper tool maintenance and real-time monitoring also play a crucial role. These practices ensure consistent accuracy and help you achieve the desired results.

What role does material selection play in CNC machining?

Material selection affects machinability, thermal stability, and tool wear. Harder materials may require slower cutting speeds, while softer ones might expand with temperature changes. Understanding material properties helps you choose the right tools and parameters for precise machining.

How does real-time monitoring improve CNC machining accuracy?

Real-time monitoring detects deviations during machining and adjusts parameters automatically. This prevents defects, reduces tool wear, and ensures consistent quality. By using advanced monitoring systems, you can maintain tight tolerances and improve overall efficiency.

What are the benefits of multi-axis CNC machining?

Multi-axis CNC machining allows you to create complex geometries in a single setup. It reduces errors, improves precision, and minimizes production time. This technology is ideal for industries requiring intricate designs and high accuracy.

See Also

Achieving Precision Parts Production Through CNC Machining Mastery

Recognizing CNC Machining's Role in Precision Manufacturing Processes

Exploring Precision Engineering Through Accurate CNC Cutting Techniques

Excelling in CNC Milling for High-Quality Parts Production

Enhancing Manufacturing Quality Using Advanced CNC Machining Techniques

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com