Nondestructive Testing for CNC Machined Materials

Non-destructive testing (NDT) refers to a group of quality inspection methods used to evaluate materials or components without causing damage. This approach ensures that CNC machining processes produce parts that meet strict performance and safety standards. NDT plays a critical role in identifying defects, maintaining structural integrity, and extending the lifespan of machined components. By detecting flaws early, manufacturers can reduce waste, improve reliability, and lower production costs. These benefits make NDT an essential tool for ensuring the quality and precision of CNC machined materials.

Key Takeaways

Nondestructive testing (NDT) checks materials without breaking or harming them.

Methods like ultrasound and X-rays find hidden problems inside parts.

Picking the right method depends on material, defect spot, and price.

Using NDT saves money, cuts waste, and meets industry rules.

Skilled workers are key for good results; training helps inspections.

What is Nondestructive Testing?

Definition and Purpose

Nondestructive testing (NDT) refers to a set of quality inspection methods used to evaluate the properties of materials, components, or assemblies without causing any damage. This approach ensures that parts remain intact and functional after testing. NDT is widely used in industries where safety, reliability, and precision are critical. For CNC machined parts, NDT helps identify surface and subsurface defects, ensuring compliance with strict ndt standards and codes. By preserving the integrity of the tested components, NDT supports both manufacturing and maintenance processes.

Differences Between NDT and Destructive Testing

NDT and destructive testing (DT) serve different purposes and involve distinct methodologies. Here are the key differences:

Nondestructive testing evaluates material properties without causing damage, making it suitable for inspections and maintenance.

Destructive testing involves damaging or destroying the specimen to understand its behavior under stress, often used for research and material characterization.

NDT preserves the integrity of the sample, while DT sacrifices it, leading to different cost implications and turnaround times.

For CNC machined parts, NDT offers a significant advantage by allowing manufacturers to inspect finished products without compromising their usability. This makes it an essential tool for ensuring quality and reliability in high-precision applications.

Key Benefits for CNC Machined Parts

Nondestructive testing provides several advantages for CNC machined parts:

No Damage: NDT does not harm the part, making it ideal for testing finished products.

Real-Time Feedback: Many NDT methods provide immediate results, enabling manufacturers to detect issues during the production process.

Reduced Costs: By eliminating the need for destructive testing on every part or batch, NDT reduces material waste and testing expenses.

Compliance with Standards: NDT ensures that parts meet ndt standards and ndt codes, which are critical for industries like aerospace, automotive, and medical device manufacturing.

Enhanced Dimensional Inspection: NDT complements dimensional inspection techniques by identifying internal flaws that may not be visible externally.

These benefits make NDT an indispensable tool for maintaining the quality and reliability of cnc machined parts while optimizing production efficiency.

Common NDT Methods for CNC Machined Parts

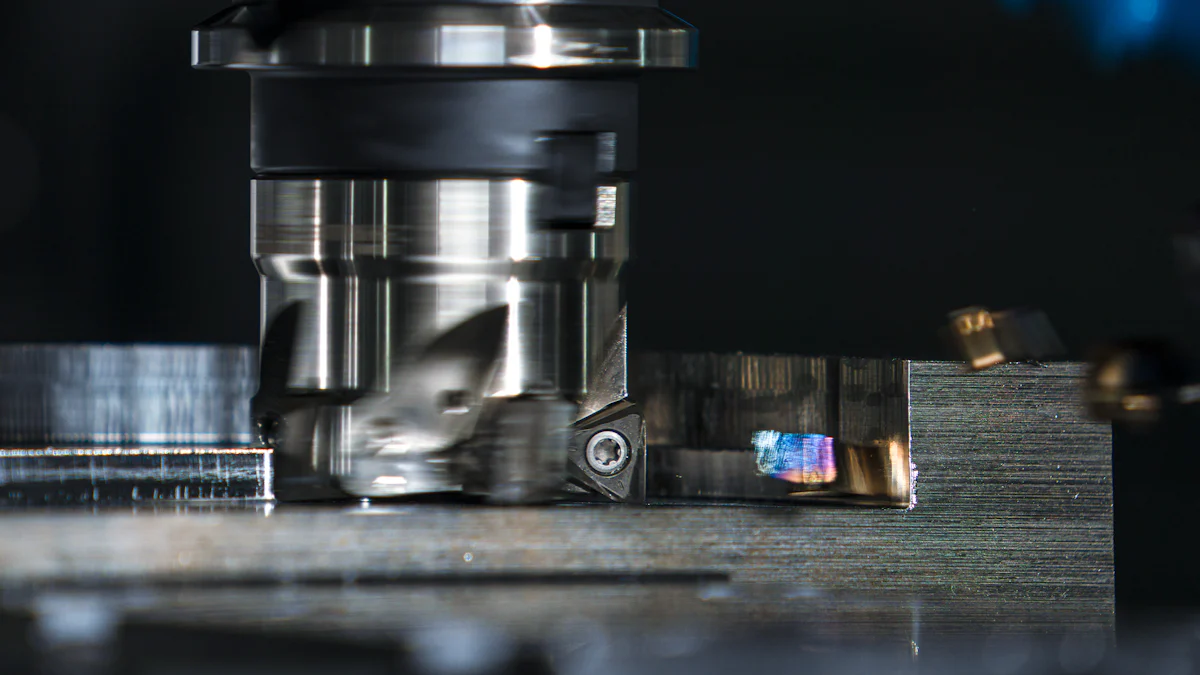

Visual Inspection

Visual inspection is one of the simplest and most widely used ndt methods for evaluating cnc machined parts. This technique involves examining the surface of a component for visible defects such as cracks, scratches, or irregularities. Inspectors often use tools like magnifying glasses, borescopes, or even advanced optical systems to enhance their ability to detect flaws. Visual inspection is particularly effective for identifying surface-level issues that could compromise the functionality or appearance of a part. Its simplicity and cost-effectiveness make it an essential step in the quality control process for cnc machining.

Although visual inspection is straightforward, it requires trained personnel to ensure accuracy. Inspectors must have a keen eye for detail and a thorough understanding of the part's specifications. While this method cannot detect internal defects, it serves as a valuable first line of defense in identifying potential problems.

Ultrasonic Testing

Ultrasonic testing (UT) is a highly effective ndt technique for detecting internal flaws in cnc machined parts. This method uses high-frequency sound waves to penetrate the material. When these waves encounter a defect, such as a crack or void, they reflect back to the transducer, creating a signal that indicates the presence of an anomaly. UT is particularly useful for inspecting thick or complex components where internal defects may not be visible externally.

This technique offers several advantages. It provides precise measurements of defect size and location, ensuring that parts meet stringent quality standards. Additionally, ultrasonic testing is non-invasive, preserving the integrity of the component. However, it requires specialized equipment and skilled operators to interpret the results accurately.

Radiographic Testing

Radiographic testing (RT) employs X-rays or gamma rays to examine the internal structure of cnc machined parts. This method is ideal for detecting internal defects, such as voids, inclusions, or cracks, without causing any damage to the component. The process involves passing radiation through the part and capturing an image on a detector or film. Any irregularities in the material density appear as variations in the image, allowing inspectors to identify flaws.

Radiographic testing is particularly valuable for high-precision industries like aerospace and medical device manufacturing, where internal integrity is critical. While this method provides detailed insights into a part's internal structure, it requires strict safety protocols and specialized equipment. Despite these challenges, RT remains one of the most reliable ndt methods for ensuring the quality of cnc machined parts.

Magnetic Particle Testing

Magnetic Particle Testing (MPT) is a widely used non-destructive testing method for detecting surface and near-surface defects in ferromagnetic materials. This technique involves magnetizing the CNC machined part and applying magnetic particles, either in dry powder form or suspended in a liquid. When a defect disrupts the magnetic field, the particles accumulate at the flaw, making it visible to the inspector.

MPT is particularly effective for identifying cracks, seams, and inclusions in CNC machined parts made from ferromagnetic materials like iron, nickel, or cobalt. It is a cost-effective and relatively simple method that provides quick results. However, it is limited to ferromagnetic materials and cannot detect defects deeper than a few millimeters below the surface. Despite these limitations, MPT remains a valuable tool in the arsenal of NDT methods for ensuring the quality of CNC machined components.

Dye Penetrant Testing

Dye Penetrant Testing (DPT) is another essential non-destructive testing technique used to identify surface defects in CNC machined parts. This method involves applying a liquid dye to the surface of the component. The dye penetrates any cracks or flaws through capillary action. After a specified dwell time, the excess dye is removed, and a developer is applied to draw out the dye from the defects, making them visible.

DPT is highly effective for detecting surface cracks, including fatigue cracks and surface fractures. It maintains the integrity of the component while providing reliable results. This method is ideal for identifying flaws that reach the surface but cannot detect subsurface defects. Its simplicity and versatility make it one of the most commonly used NDT techniques in CNC machining.

Eddy Current Testing

Eddy Current Testing (ECT) is a versatile and highly sensitive non-destructive testing method for inspecting conductive CNC machined materials. This technique uses electromagnetic induction to detect surface and near-surface defects. When an alternating current flows through a coil, it generates an electromagnetic field. As the coil passes over the material, any discontinuities disrupt the flow of eddy currents, signaling the presence of a defect.

ECT offers several advantages. It can detect small surface cracks and defects with high sensitivity. The process is fast, enabling the inspection of large volumes of conductive materials efficiently. Additionally, it can measure material conductivity, determine metal thickness, and detect thinning caused by corrosion. These capabilities make ECT one of the most advanced NDT methods for ensuring the quality and reliability of CNC machined parts.

How to Choose the Right NDT Method

Factors to Consider

Selecting the appropriate non-destructive testing method for CNC machined parts requires careful evaluation of several factors. Each method offers unique advantages and is suited for specific applications. Key considerations include:

Material Type: Different materials, such as metals, polymers, and ceramics, respond differently to testing methods. For example, ultrasonic testing works well with dense materials, while eddy current testing is ideal for conductive ones.

Stress Type: The type of stress the part will endure, whether tensile or compressive, influences the choice of testing.

End Use: The operating conditions, such as exposure to high temperatures, fatigue, or corrosive environments, determine the testing requirements.

Defect Location: Surface-level defects may require dye penetrant testing, while internal flaws might necessitate radiographic or ultrasonic testing.

Cost and Time: Some methods, like visual inspection, are cost-effective and quick, while others, such as radiographic testing, involve higher costs and longer processing times.

By considering these factors, manufacturers can ensure the chosen method aligns with the specific needs of the CNC machined parts.

Step-by-Step Guide for Selection

Choosing the right non-destructive testing method involves a systematic approach. Follow these steps to make an informed decision:

Identify the Material: Determine the material composition of the CNC machined part. For ferromagnetic materials, magnetic particle testing is effective, while eddy current testing suits conductive materials.

Define the Defect Type: Specify whether the defect is likely to be surface-level, subsurface, or internal. This helps narrow down the testing options.

Assess the Application: Consider the part's end use and the stresses it will face. For example, aerospace components may require radiographic testing due to stringent safety standards.

Evaluate Testing Capabilities: Match the testing method to the required precision and defect detection capabilities. Ultrasonic testing, for instance, excels at detecting internal flaws.

Consider Budget and Resources: Balance the cost of testing with the available equipment and expertise. Dye penetrant testing offers a cost-effective solution for surface defects, while radiographic testing demands specialized equipment.

Consult Standards: Ensure the selected method complies with industry standards and codes relevant to CNC machining.

This structured approach simplifies the selection process and ensures the chosen method meets the quality and reliability requirements of CNC machined parts.

Applications of NDT in CNC Machining

Aerospace Industry

Non-destructive testing plays a critical role in the aerospace industry, where safety and reliability are paramount. These techniques help minimize costs while enhancing safety in aviation. Aircraft parts undergo rigorous evaluation and certification to prevent costly repairs and ensure operational integrity. Scheduled maintenance often includes NDT methods to identify flaws and wear effects promptly.

Visual inspection detects surface issues like cracks, leaks, and rust.

Laser testing methods identify surface variations and imperfections.

Liquid penetrant testing proves effective for routine inspections of aircraft engines.

Acoustic emission testing detects leaks and corrosion in pressurized vessels.

By employing these methods, aerospace manufacturers ensure that CNC machined components meet stringent safety and performance standards.

Automotive Industry

In the automotive sector, non-destructive testing ensures the safety and reliability of vehicles by enabling thorough inspections without damaging components. This approach supports quality assurance during manufacturing by identifying defects that could compromise vehicle safety or performance.

Advanced methods, such as digital radiographic computed tomography (CT), enhance the inspection of critical components like engine blocks and wheels.

NDT techniques help manufacturers detect flaws early, reducing the risk of accidents caused by defective parts.

These practices ensure that CNC machined automotive components meet high-quality standards, contributing to safer and more reliable vehicles.

Medical Device Manufacturing

Non-destructive testing is essential in medical device manufacturing, where precision and safety are non-negotiable. This process identifies defects like cracks and design flaws early, preventing potential injuries or fatalities. It also ensures that medical devices comply with quality standards set by regulatory bodies, protecting manufacturers from legal issues.

By integrating NDT into the production of CNC machined medical devices, manufacturers can deliver products that meet stringent safety and performance requirements. This approach not only enhances patient safety but also upholds the reputation of medical device companies.

Challenges and Limitations of NDT

Cost and Equipment Requirements

Nondestructive testing (NDT) offers significant advantages, but its implementation can involve substantial costs. Advanced NDT techniques, such as ultrasonic or radiographic testing, require specialized equipment that may represent a significant investment for manufacturers. Additionally, maintaining and calibrating this equipment adds to operational expenses. Despite these costs, NDT methods provide real-time assessments of materials, reducing the need for destructive testing. This is particularly beneficial in high-volume production environments, where minimizing waste and ensuring quality are critical. By enabling the inspection of high-precision components without damaging them, NDT helps manufacturers maintain functionality while confirming integrity.

Operator Expertise

The effectiveness of NDT depends heavily on the expertise of the operators performing the tests. Different methods require varying levels of skill and training. For example:

Visual inspection relies on experienced inspectors to identify visible defects accurately.

Ultrasonic testing demands careful calibration and skilled operators to locate flaws and assess material integrity.

Without proper training, operators may misinterpret results, leading to inaccurate assessments. This reliance on expertise highlights the importance of investing in operator training programs to ensure consistent and reliable quality inspection methods.

Limitations of Specific NDT Methods

Each NDT method has inherent limitations that may restrict its application. For instance, magnetic particle testing works only on ferromagnetic materials and cannot detect deep subsurface defects. Similarly, dye penetrant testing is limited to surface-level flaws and cannot identify internal issues. Radiographic testing, while highly effective, involves strict safety protocols due to radiation exposure. These limitations require manufacturers to carefully evaluate the suitability of each method based on the material, defect type, and application. Selecting the wrong method could result in undetected flaws, compromising the quality and reliability of CNC machined parts.

Non-destructive testing ensures the quality and reliability of CNC machined materials by identifying flaws without damaging the components. It verifies that machining processes meet design specifications and industry standards. Manufacturers benefit from real-time feedback, reduced costs, and the ability to maintain product integrity during inspections. Techniques like ultrasonic testing, radiographic testing, and dye penetrant testing enhance defect detection across various applications. By integrating NDT into their workflows, manufacturers can improve efficiency, minimize waste, and deliver high-quality products that meet stringent requirements.

FAQ

What is the primary advantage of nondestructive testing for CNC machined parts?

Nondestructive testing ensures the integrity of CNC machined parts without causing damage. This allows manufacturers to inspect components for defects while preserving their usability. It reduces waste, enhances reliability, and ensures compliance with industry standards, making it an essential quality assurance tool.

Can nondestructive testing detect internal defects in materials?

Yes, methods like ultrasonic testing and radiographic testing can identify internal defects. These techniques use sound waves or radiation to detect flaws beneath the surface, ensuring that CNC machined parts meet strict quality and safety requirements.

Is nondestructive testing suitable for all materials?

Not all NDT methods work for every material. For example, magnetic particle testing applies only to ferromagnetic materials, while eddy current testing requires conductive materials. Manufacturers must select methods based on the material type and testing requirements.

How does operator expertise impact nondestructive testing?

Operator expertise significantly affects the accuracy of NDT results. Skilled operators can correctly calibrate equipment, interpret data, and identify defects. Insufficient training may lead to errors, compromising the reliability of the inspection process.

Are nondestructive testing methods cost-effective?

NDT methods can be cost-effective by reducing waste and preventing costly failures. While some techniques require expensive equipment, the ability to inspect parts without damage offsets these costs. This makes NDT a valuable investment for high-precision industries.

See Also

Key Insights Into Material Needs for CNC Machining

Discovering CNC Machining's Accuracy Within Aerospace Applications

A Comprehensive Overview of CNC Machining Processes

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com