Powder Metallurgy vs. Traditional CNC Machining

When choosing between Powder Metallurgy and CNC Machining, understanding their core difference is essential. Powder Metallurgy, an additive manufacturing method, builds parts by fusing metal powders, while CNC Machining removes material from a solid block to shape the final product. Your decision depends on factors like design flexibility, material strength, and cost. For example, CNC Machining excels in precision and complexity, but it generates significant material waste—up to 50%. In contrast, Powder Metallurgy achieves a scrap rate as low as 3%, making it one of the most efficient metalworking processes. Knowing these benefits and limitations helps you select the right approach for your project.

Key Takeaways

Powder Metallurgy is very efficient. It uses almost all materials. It creates only about 3% waste, great for big projects.

CNC Machining is very precise. It works best for small jobs. It sets up fast and doesn’t need costly tools.

Use Powder Metallurgy for tricky designs with detailed shapes. It’s great for making complex parts.

CNC Machining is flexible. It works with many materials. It’s good for tough-to-make parts.

Think about the environment: Powder Metallurgy wastes less and uses less energy than CNC Machining.

Overview of Powder Metallurgy

What is Powder Metallurgy?

Powder metallurgy is a manufacturing process that creates metal parts by compressing and sintering metal powders. Unlike traditional methods, it builds components by adding material rather than removing it. This technique has ancient roots. The Incas used metal powders to craft jewelry and artifacts. However, modern powder metallurgy began in the 19th century. Early methods involved extracting iron from sponges and reintroducing it as powder for sintering. Today, it is a highly advanced process used to produce precise and durable parts.

Key Steps in the Powder Metallurgy Process

Powder metallurgy follows a systematic approach to create high-quality components. The process includes:

Blending: Fine metal powders mix with additives to achieve the desired properties.

Compacting: The mixture is pressed into a die to form the required shape.

Sintering: The compressed material is heated in a controlled atmosphere. This step bonds the particles, resulting in near-net shape parts with excellent strength and precision.

These steps ensure that powder metallurgy delivers consistent results, even for complex designs.

Advantages of Powder Metallurgy

Powder metallurgy offers several benefits over traditional manufacturing methods. It minimizes material waste, utilizing nearly all the starting material. This makes it one of the most efficient processes available. The ability to produce intricate shapes and fine details is another key advantage. You can achieve net shape parts without the need for extensive machining. Additionally, the process ensures consistent quality, which is crucial for applications requiring precise dimensions.

Advantage | Description |

|---|---|

Material Efficiency | Utilizes nearly all the starting material, significantly reducing waste compared to other methods. |

Complex Geometry | Allows for the production of intricate shapes and fine details that are difficult or costly to achieve with traditional methods. |

Consistent Quality | Ensures high part-to-part consistency, crucial for applications requiring precise dimensions. |

Customization | Enables production of parts with specific characteristics by tailoring material properties. |

Energy Efficiency | Requires lower temperatures during sintering, consuming less energy than melting metals. |

The advantages of powder metallurgy make it ideal for high-volume production and applications requiring precision. Its energy efficiency and ability to create near-net shape parts further enhance its appeal.

Limitations of Powder Metallurgy

While powder metallurgy offers many advantages, it also comes with notable limitations that you should consider before choosing this process. One of the primary challenges lies in size and shape constraints. The process struggles to produce large or highly complex parts. If your project requires oversized components or intricate designs, powder metallurgy may not meet your needs.

Another limitation is the difficulty in achieving consistent density throughout the part. Uneven density can weaken the mechanical properties, such as strength and toughness. This issue becomes more pronounced in applications where durability is critical. Additionally, the inherent porosity of parts made through powder metallurgy can further compromise their structural integrity. Porosity often leads to reduced resistance to stress and wear, which might not be suitable for high-performance applications.

The economic aspect is another factor to weigh. Powder metallurgy involves high initial costs for tooling and equipment. If your production volume is low, the process may not be cost-effective. Small batch production often makes the investment in specialized machinery and dies impractical. For this reason, powder metallurgy is better suited for high-volume manufacturing.

Design limitations also restrict the types of features you can create. For example, sharp corners, undercuts, or thin walls are difficult to achieve with this method. If your design requires such features, you may need to explore alternative manufacturing processes.

Understanding these limitations helps you evaluate whether powder metallurgy aligns with your project requirements. While it excels in efficiency and precision for certain applications, its constraints can impact feasibility for others.

Overview of CNC Machining

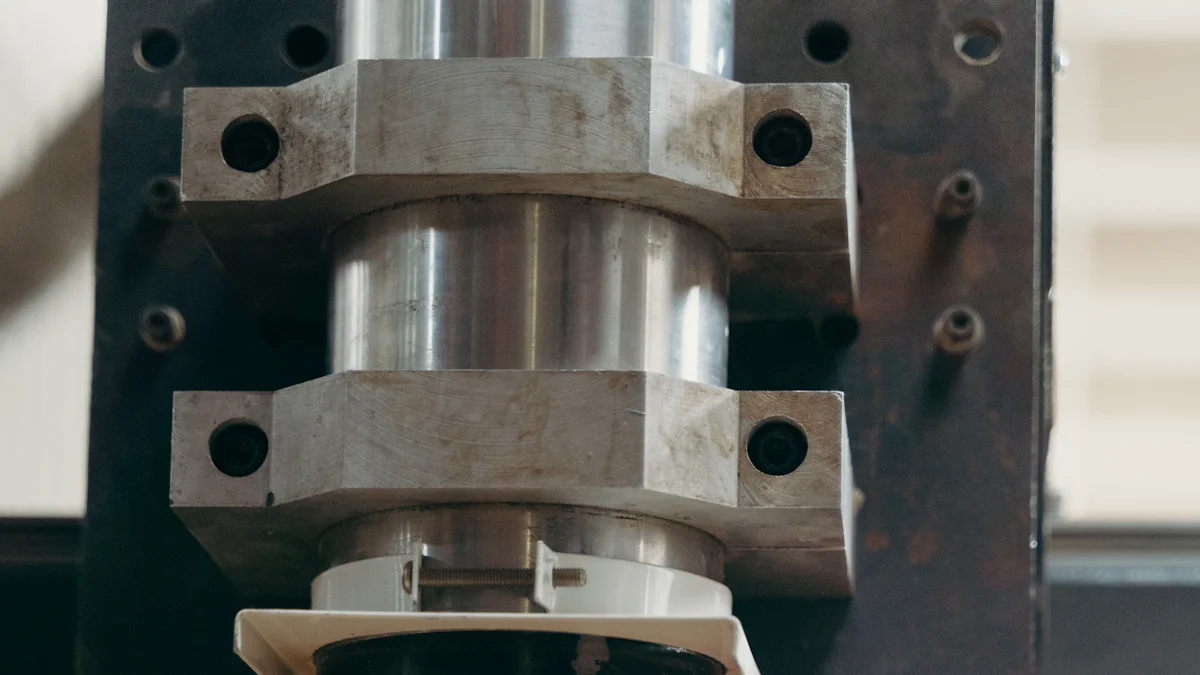

What is CNC Machining?

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to shape materials into precise components. The term "CNC" stands for Computer Numerical Control, which refers to the automated control of machining tools through pre-programmed software. This process removes material from a solid block, known as a workpiece, to create the desired shape.

The history of CNC machining dates back to the late 1940s when John Parsons developed the first system using coded punch cards to control machining equipment. This innovation marked the beginning of automated manufacturing. Over the decades, CNC machining evolved significantly. By the 1950s, Richard Kegg and MIT introduced the first CNC milling machine. Later advancements, such as the integration of Computer-Aided Design (CAD) and Computer-Aided Machining (CAM) in the 1970s, revolutionized the industry. Today, CNC machining plays a vital role in producing complex and precise components across various industries.

Key Steps in the CNC Machining Process

The CNC machining process involves several key steps to ensure accuracy and efficiency:

Designing the CAD Model: You start by creating a digital design of the part using CAD software.

Converting to CAM: The CAD file is converted into a CAM program, which generates the toolpaths and instructions for the CNC machine.

Machine Setup: The workpiece is secured on the machine, and the appropriate tools are installed.

Machining: The CNC machine follows the programmed instructions to cut, drill, or mill the material, shaping it into the final product.

Finishing and Inspection: After machining, the part undergoes finishing processes like polishing or deburring, followed by quality inspection to ensure it meets specifications.

These steps allow CNC machining to deliver consistent and high-quality results.

Advantages of CNC Machining

CNC machining offers several advantages that make it a preferred choice for many manufacturing applications:

High Accuracy: The use of digital templates minimizes human error, ensuring precise outputs.

Complex Designs: CNC machines can produce intricate shapes and geometries that are difficult to achieve manually.

Versatility: This process accommodates a wide range of materials and can create diverse components for various industries.

Less Dependence on Human Labor: The autonomous nature of CNC machines reduces the need for manual intervention, enhancing efficiency.

Scalability: CNC machining is suitable for both small-batch and large-scale production, making it adaptable to different project needs.

The global CNC machining market reflects its growing importance. By 2026, it is projected to reach $128.86 billion, driven by the demand for automation and efficiency in industries like automotive, defense, and medical. This growth highlights the process's ability to meet modern manufacturing challenges.

Limitations of CNC Machining

CNC machining, while highly versatile, comes with its own set of limitations that you should consider. One of the most significant drawbacks is material waste. Since CNC machining is a subtractive process, it removes material from a solid block to create the final part. This often results in considerable waste, especially when working with expensive materials like titanium or stainless steel. In contrast, powder metallurgy uses nearly all the starting material, making it far more efficient.

Another limitation lies in design flexibility. CNC machining struggles to produce components with undercuts, internal cavities, or other complex geometries. These features require specialized tools or additional processes, which can increase production time and costs. Powder metallurgy, on the other hand, excels at creating intricate shapes and fine details without the need for extensive post-processing.

Machining hard materials can also pose challenges. Materials like stainless steel or exotic alloys require advanced tools and slower machining speeds, which can drive up costs. Additionally, the wear and tear on cutting tools increase when working with such materials, leading to higher maintenance expenses.

💡 Tip: If your project involves hard-to-machine materials or highly complex designs, consider alternative methods like powder metallurgy for better results.

CNC machining's subtractive nature also limits its environmental efficiency. The process generates a significant amount of scrap material, which often requires recycling or disposal. This contrasts with powder metallurgy, which minimizes waste and energy consumption.

Lastly, CNC machining may not be the best choice for high-volume production. The time required for setup, programming, and machining each part can make it less cost-effective for large-scale manufacturing. Powder metallurgy, with its ability to produce parts in bulk, often proves more economical for such applications.

Understanding these limitations helps you evaluate whether CNC machining aligns with your project needs. While it offers precision and versatility, its constraints may impact feasibility for certain designs or materials.

Comparative Analysis

Design Flexibility

When it comes to design flexibility, Powder Metallurgy outshines CNC Machining in several ways. Its additive nature allows you to create advanced part designs from scratch. This makes it ideal for producing intricate features and complex geometries. Powder Metallurgy can handle:

Undercuts and internal cavities that CNC machining struggles to achieve.

Controlled porosity, which enhances its ability to meet specific design requirements.

CNC Machining, on the other hand, excels at creating precise shapes but faces challenges with highly intricate designs. Features like sharp internal corners or deep cavities often require additional tools or processes, increasing production time and cost. If your project demands complex geometries, Powder Metallurgy offers a more efficient solution.

Accuracy and Precision

CNC Machining leads the way in accuracy and precision. Its automated processes ensure tight tolerances and consistent dimensional quality. This makes it the go-to choice for applications requiring exact measurements. CNC machines can achieve unmatched precision, especially when advanced technology is used.

Powder Metallurgy, while reliable, cannot match the dimensional precision of CNC Machining. However, it offers other advantages. The process produces parts with minimal errors and consistent microstructures. This reduces the need for secondary machining. Powder Metallurgy also provides excellent part-to-part repeatability, though thermal processes during sintering may introduce slight distortions. If your project prioritizes dimensional accuracy, CNC Machining is the better option.

Material Strength and Durability

Material strength and durability differ significantly between the two processes. CNC Machining produces parts with higher strength because it works with solid materials. This makes it suitable for high-performance applications.

Powder Metallurgy parts, however, have inherent porosity, which can limit their strength. Despite this, the sintering process creates strong bonds between metal particles, resulting in durable components. Powder Metallurgy can achieve high durability, but it may not match the strength of CNC Machined parts. If your project requires maximum strength, CNC Machining is the preferred choice. For applications where durability and efficiency matter more, Powder Metallurgy offers a viable alternative.

Cost Efficiency

Understanding cost efficiency is crucial when deciding between Powder Metallurgy and CNC Machining. Each process has distinct advantages depending on your production needs.

Powder Metallurgy stands out for high-volume production. Its efficient material use and low scrap rate—around 3%—make it a cost-effective choice. You can produce large quantities of parts with minimal waste, reducing overall expenses. Additionally, Powder Metallurgy supports faster production times for complex designs, further lowering costs.

CNC Machining, however, excels in low-volume production. It eliminates the need for expensive tooling, which makes it ideal for small runs or prototypes. The setup process is quicker, allowing you to start production without significant delays. Despite this, CNC Machining can become costly for large-scale manufacturing. The subtractive nature of the process generates up to 50% material waste, increasing expenses, especially when using premium materials.

Factor | Powder Metallurgy | CNC Machining |

|---|---|---|

Material Waste | ~3% | Up to 50% |

Tooling Costs | High initial investment | Minimal for small runs |

Suitability | Best for high-volume production | Best for low-volume production |

Choosing the right process depends on your production scale. For mass production, Powder Metallurgy offers unmatched efficiency. For smaller projects, CNC Machining provides flexibility without high upfront costs.

Environmental Impact

The environmental impact of manufacturing processes is an important consideration. Powder Metallurgy and CNC Machining differ significantly in their sustainability.

Powder Metallurgy is recognized as a highly sustainable process. It minimizes waste with a scrap rate of only 3%, compared to CNC Machining’s 50%. This efficient material usage reduces the need for recycling or disposal. Additionally, Powder Metallurgy consumes less energy by operating at lower temperatures during sintering. The process also generates fewer harmful emissions, making it an eco-friendly choice.

CNC Machining, while precise, has a higher environmental footprint. Its subtractive nature leads to significant material waste, which often requires energy-intensive recycling. Machining hard materials further increases energy consumption. If sustainability is a priority, Powder Metallurgy offers a greener alternative.

🌱 Tip: Opt for Powder Metallurgy when you need an energy-efficient process with minimal waste. It’s a step toward reducing your project’s environmental impact.

By understanding these differences, you can align your manufacturing choices with your environmental goals.

Applications and Industries

Applications of Powder Metallurgy

Powder metallurgy plays a vital role in modern manufacturing. Its ability to create complex shapes and minimize material waste makes it suitable for various applications. You’ll find it widely used in the automotive sector, where it produces components like engine parts, gears, and bearings. These parts often include sprockets for timing systems, clutch components, and structural elements. The process also supports emission system components and electrical parts, ensuring high performance and durability.

In agriculture, powder metallurgy contributes to machinery parts such as gears, planter plates, and cutting tools. It also produces filters and pump components, which are essential for efficient operations. This versatility allows you to use powder metallurgy for both small and large-scale manufacturing needs.

Applications of CNC Machining

CNC machining offers unmatched precision and versatility, making it indispensable across industries. In aerospace, it produces airfoils, landing gear, and antennae. Automotive manufacturers rely on CNC machining for gearboxes, axles, and engine parts. The marine industry uses it for deck and hull structures, while electronics benefit from components like PCBs and housings.

Healthcare applications include bone screws, surgical instruments, and prosthetics. CNC machining also supports energy projects by creating turbine blades and solar panel frames. In agriculture, it manufactures tractor components and irrigation parts. Even the food and beverage industry uses CNC waterjet cutters for food processing and packaging equipment. This adaptability ensures you can meet diverse manufacturing requirements with CNC machining.

Industries Using Powder Metallurgy

Many industries depend on powder metallurgy for its efficiency and precision. The automotive sector uses it for transmission gears, clutch parts, and exhaust systems. Industrial machinery benefits from bearings, bushings, and hydraulic components. In the medical field, powder metallurgy produces surgical instruments and orthopedic implants. Aerospace applications include structural components, thermal shields, and fasteners.

The electrical and electronics industry relies on powder metallurgy for magnetic cores and heat sinks. Consumer goods manufacturers use it for kitchen appliances and power tools. Even construction benefits from powder metallurgy, with products like door locks and structural fittings. Its ability to create intricate designs and reduce waste makes it a preferred choice across these industries.

Industries Using CNC Machining

CNC machining plays a crucial role in many industries due to its precision and versatility. You’ll find it indispensable in sectors where accuracy and reliability are non-negotiable. Here’s a closer look at how different industries benefit from this advanced manufacturing process:

Industry | Application |

|---|---|

Aerospace | Producing products that meet high standards. |

Automotive | Manufacturing parts like engine blocks and transmission components for reliable vehicles. |

Medical | Creating complex devices such as implants and surgical instruments with precise specifications. |

Military | Producing weapons, ammunition, and military vehicles with exact specifications. |

Industrial | Manufacturing machinery for food and beverage packaging and material handling systems. |

Energy | Producing parts for wind turbines and solar panels. |

Marine | Ensuring performance and safety of vessels. |

Agriculture | Making components for farm machinery. |

Consumer Goods | Manufacturing electronics, appliances, and toys with high accuracy. |

Electronics | Producing small, intricate parts requiring high precision. |

In the aerospace industry, CNC machining ensures that parts meet strict safety and performance standards. You can rely on it to produce components like airfoils and landing gear with unmatched precision. Similarly, the automotive sector depends on CNC machining for engine blocks, axles, and other critical parts that keep vehicles running smoothly.

The medical field uses CNC machining to create implants, surgical tools, and prosthetics. These devices require exact specifications to ensure patient safety and effectiveness. In the military, CNC machining is essential for manufacturing weapons, ammunition, and vehicles that meet rigorous demands.

You’ll also see CNC machining in industrial applications, such as food and beverage packaging machinery. It’s vital for creating durable and efficient systems. The energy sector benefits from CNC machining for producing wind turbine components and solar panel frames, supporting renewable energy initiatives.

In marine industries, CNC machining ensures the safety and performance of vessels by producing high-quality structural parts. For agriculture, it manufactures components for tractors and irrigation systems, improving farming efficiency. The consumer goods and electronics industries rely on CNC machining for producing intricate parts for appliances, toys, and gadgets.

CNC machining’s adaptability makes it a cornerstone of modern manufacturing. Whether you’re working in aerospace or agriculture, this process delivers the precision and reliability you need.

Decision-Making Factors

Design Complexity and Requirements

Your project's design complexity plays a significant role in choosing between powder metallurgy and CNC machining. Powder metallurgy offers exceptional flexibility for creating intricate shapes. It allows you to manufacture components with undercuts, internal cavities, and advanced geometries that CNC machining often struggles to achieve. This makes it ideal for designs requiring unique features or controlled porosity. However, certain elements, like threads or sharp corners, may need additional machining after the initial process.

CNC machining, on the other hand, excels in precision. It produces highly accurate parts and handles a wide variety of materials. If your design involves low-volume production with complex but precise requirements, CNC machining becomes a practical choice. While it may not match the design flexibility of powder metallurgy, it ensures tight tolerances and consistent quality.

Material Properties and Selection

The material you choose directly impacts the manufacturing process. Powder metallurgy works well with materials like stainless steel and cobalt chrome. Stainless steel offers excellent corrosion resistance, making it suitable for kitchenware and medical implants. Cobalt chrome provides superior wear resistance and high-temperature strength, ideal for turbine blades and high-performance components.

CNC machining accommodates a broader range of materials, including metals, plastics, and composites. This versatility allows you to select materials based on specific project needs. For example, if you require a lightweight yet durable material, CNC machining can handle aluminum or titanium with ease. Powder metallurgy, while efficient, may not support the same material diversity.

Production Volume and Cost

Production volume significantly affects cost efficiency. Powder metallurgy shines in high-volume manufacturing. Its low scrap rate and efficient material use reduce overall expenses. As production quantities increase, the cost per part decreases, making it a cost-effective option for mass production. However, for small production runs, the high initial tooling costs make powder metallurgy less economical.

CNC machining is better suited for low-volume production. It eliminates the need for expensive tooling, which keeps costs manageable for prototypes or small batches. While the subtractive nature of CNC machining generates more waste, it remains a practical choice for short product runs. For large-scale manufacturing, though, powder metallurgy offers better cost efficiency.

💡 Tip: Consider powder metallurgy for high-volume projects and CNC machining for smaller, precise runs to optimize costs.

Environmental Considerations

When evaluating manufacturing processes, you should consider their environmental impact. Powder Metallurgy and CNC Machining differ significantly in this area, and understanding these differences can help you make a more sustainable choice.

Powder Metallurgy stands out as one of the most eco-friendly metalworking methods. Its additive nature ensures that only the material required for the design is used. This process generates minimal waste, with a scrap rate of just 3%. By conserving raw materials, Powder Metallurgy reduces the need for recycling or disposal. It also operates at lower temperatures during sintering, which consumes less energy compared to melting metals. These factors make it an excellent option if you prioritize sustainability in your projects.

CNC Machining, while precise, has a higher environmental footprint. Its subtractive approach removes material from a solid block, often resulting in up to 50% waste. Although you can recycle the scrap, the energy required for recycling adds to the overall environmental cost. Additionally, machining hard materials like titanium or stainless steel increases energy consumption due to the need for advanced tools and slower cutting speeds. If your project involves high material waste, CNC Machining may not align with your environmental goals.

🌍 Note: Choosing Powder Metallurgy can significantly reduce your project's material waste and energy use. It’s a step toward more sustainable manufacturing practices.

Factor | Powder Metallurgy | CNC Machining |

|---|---|---|

Material Waste | ~3% | Up to 50% |

Energy Efficiency | Lower energy consumption | Higher energy consumption |

Recycling Needs | Minimal | Significant |

By comparing these processes, you can align your manufacturing decisions with your environmental priorities. Powder Metallurgy offers a greener alternative, especially for high-volume production. CNC Machining, while versatile, may require additional considerations to offset its environmental impact.

Choosing between Powder Metallurgy and CNC Machining depends on your project’s goals. Powder Metallurgy works best for high-volume production. It minimizes waste, uses materials efficiently, and creates complex shapes with fewer steps. CNC Machining, however, excels in precision and versatility. It’s ideal for low-volume production or when working with high-performance materials.

Key Takeaways:

Powder Metallurgy Advantages:

Efficient material use

Lower energy consumption

Ability to create intricate designs

CNC Machining Advantages:

High accuracy for short runs

No tooling costs

Suitable for hard-to-machine materials

💡 Tip: For large-scale manufacturing, choose Powder Metallurgy. For prototypes or small batches, CNC Machining offers better flexibility. Always align the process with your design, material, and cost requirements.

FAQ

What is the main difference between Powder Metallurgy and CNC Machining?

Powder Metallurgy is an additive process that builds parts by fusing metal powders. CNC Machining is subtractive, removing material from a solid block to shape the final product. Your choice depends on factors like design complexity, material efficiency, and production volume.

Which process is better for high-volume production?

Powder Metallurgy is better for high-volume production. It minimizes material waste, reduces costs, and produces consistent parts efficiently. CNC Machining, while precise, becomes less cost-effective for large-scale manufacturing due to higher material waste and longer production times.

Can CNC Machining handle complex designs?

CNC Machining can create intricate designs but struggles with features like undercuts or internal cavities. These require additional tools or processes. Powder Metallurgy excels at producing complex geometries without extra steps, making it more suitable for advanced designs.

Is Powder Metallurgy environmentally friendly?

Yes, Powder Metallurgy is highly sustainable. It generates minimal waste (around 3%) and consumes less energy during production. CNC Machining, in contrast, produces significant scrap material and requires more energy, especially when machining hard materials.

How do I choose the right process for my project?

Consider your project’s design complexity, material requirements, production volume, and budget. Powder Metallurgy works best for high-volume, intricate designs. CNC Machining is ideal for low-volume production or when precision and material versatility are priorities.

See Also

Delving Into CNC Machining For Accurate Metal Fabrication

A Comprehensive Guide To CNC Precision Machining Techniques

An Overview Of Precision Machining Methods And Uses

Comparing CNC And Traditional Manufacturing Across Various Sectors

Investigating CNC Machining Solutions For High-Quality Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com