The Precision of CNC in Aluminum Parts Production

CNC machining delivers unmatched precision when producing aluminum parts for military applications. You benefit from its ability to create components with complex geometries while minimizing errors. This technology ensures consistent accuracy, which is vital for defense equipment. Aluminum’s lightweight nature and high strength-to-weight ratio enhance mobility in military vehicles without compromising durability. Its corrosion resistance ensures long-term performance in harsh environments. When combined with CNC machining, aluminum becomes indispensable for crafting reliable and efficient components, from weapon systems to armored vehicles, meeting the rigorous demands of military operations.

Key Takeaways

CNC machines make aluminum parts very accurate, which is key for military use. This reduces mistakes and meets strict rules.

Aluminum is light and doesn’t rust, making it great for military vehicles and tools. It helps them last longer and move easily.

CNC machines can create detailed shapes, keeping the quality high for complex military designs.

CNC machining works fast, making many parts quickly. This saves money and time while keeping parts strong.

CNC machines can make custom parts for military needs. They also help create new designs quickly for changing defense demands.

Overview of CNC Technology

What is CNC?

CNC, or Computer Numerical Control, refers to a manufacturing process where machines operate based on pre-programmed computer instructions. These machines use G-code, a programming language, to control movements and operations with exceptional precision. Unlike manual machining, CNC eliminates human error, ensuring consistent quality in every part produced. This technology has revolutionized industries by enabling the creation of intricate designs and complex geometries that were once impossible to achieve.

CNC machining plays a vital role in modern manufacturing, especially in producing military-grade components. Its ability to meet strict tolerances and deliver high accuracy makes it indispensable for defense applications. From aircraft parts to weapon systems, CNC ensures that every component adheres to rigorous performance standards.

Core Principles of CNC Machining

CNC machining operates on several fundamental principles that contribute to its precision and efficiency:

Computerized Control: Machines are controlled by computer systems using G-code, ensuring precise movements and operations.

Precision and Accuracy: CNC machining produces parts with tight tolerances, reducing errors compared to manual methods.

Automation: Automated processes increase productivity and maintain consistent quality across high-volume production.

Versatility: CNC machines handle various materials and perform multiple operations, making them highly adaptable.

These principles allow CNC technology to deliver reliable results, even for the most demanding applications like military manufacturing.

Applications of CNC in Manufacturing

CNC technology is widely used across industries due to its versatility and efficiency. Common applications include:

Aerospace: Airfoils, landing gear, and electrical connectors.

Automotive: Engine parts, gearboxes, and dashboard panels.

Electronics: PCBs, housings, and semiconductor components.

Healthcare: Surgical instruments, bone screws, and prosthetics.

Agriculture: Tractor components, irrigation parts, and harvesters.

Food and Beverage: Food processing tools, molds, and packaging equipment.

Marine: Hull structures, deck components, and interior furnishings.

Energy: Turbine blades, valves, and generator housings.

Robotics: Robotic arms, sensors, and fixtures.

CNC machining's adaptability makes it a cornerstone of modern manufacturing, enabling the production of high-quality parts for diverse applications.

Importance of Aluminum in Military Applications

Key Properties of Aluminum for Military Use

Aluminum offers unique properties that make it ideal for military applications. Its lightweight nature allows you to build armored vehicles that are both robust and mobile. This balance between strength and weight ensures vehicles can withstand ballistic threats while maintaining high performance. Aluminum naturally resists corrosion by forming a protective layer when exposed to air. This feature is crucial for military equipment operating in harsh environments, as it enhances durability and reduces maintenance costs. Additionally, aluminum alloys are engineered to endure mechanical stress from impacts and rough terrains, extending the lifespan of military vehicles. These qualities make aluminum a reliable material for long-term use in defense.

Why Aluminum Parts Are Essential in Defense

Aluminum plays a critical role in defense manufacturing due to its versatility and performance. Missiles like the Hawk and Polaris rely on aluminum for their speed and structural integrity. For example, the Polaris missile incorporates 4,000 pounds of aluminum, which contributes to its lightweight design, improving range and fuel efficiency. Aluminum's corrosion resistance ensures these missiles remain effective over time, a vital factor for military reliability. Shaped charge warheads also benefit from aluminum, as it enhances their ability to penetrate armor. Furthermore, aluminum is integral to missile structural components and electronic systems, ensuring dependable performance during transport and flight. Its combination of strength, durability, and lightweight properties makes aluminum indispensable in defense.

Common Military Uses of Aluminum Components

You will find aluminum in a wide range of military applications. Military vehicles, such as the Army's mobile floating assault bridge (MFAB), use aluminum alloys for their construction. Ammunition components, including projectiles and cartridges, increasingly utilize aluminum for its cost-effectiveness and reliability. Firearms like the M-16 rifle and M-60 machine gun feature aluminum parts to reduce weight, improving maneuverability. Torpedoes, such as the Mark 37 and 48, incorporate aluminum in their shells and machinery to enhance performance. Military aircraft, including the F-22 fighter jet, heavily rely on aluminum for its lightweight and high strength-to-weight ratio. Missiles, such as the Hawk and Polaris, also use aluminum to achieve greater speed and maneuverability. These examples highlight aluminum's versatility and importance in modern military technology.

CNC's Role in Aluminum Parts Production

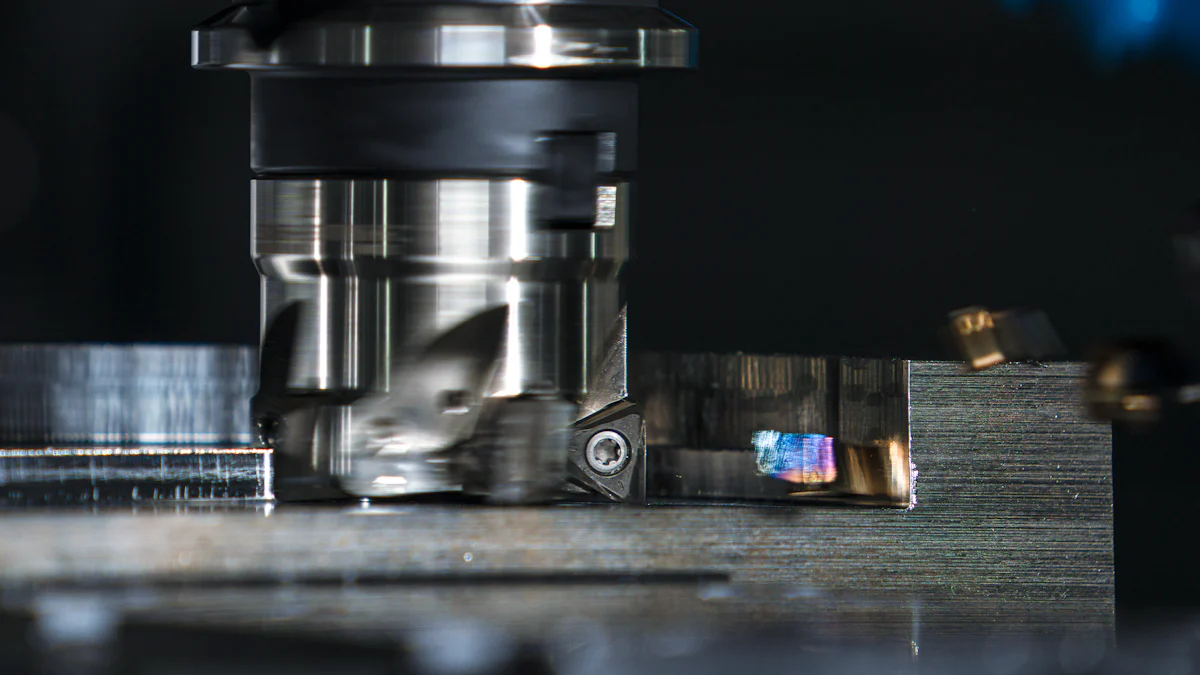

Precision in Manufacturing Aluminum Parts

CNC machining delivers unmatched precision in producing aluminum parts for military applications. You can rely on its ability to meet the strict tolerances required for critical components. This precision ensures that parts perform reliably under extreme conditions, such as high temperatures or intense mechanical stress. CNC machines achieve tolerances as low as a few microns, which is essential for military specifications.

Tip: CNC machining minimizes human error by using computer-controlled systems. This guarantees consistent quality in every part produced.

The process also incorporates advanced quality control measures. Tools like micrometers and coordinate measuring machines (CMMs) inspect parts during and after machining. These inspections ensure that every component meets the desired specifications before assembly. By maintaining high accuracy, CNC machining enhances the effectiveness of military equipment, from aircraft to weaponry.

Consistency in Complex Geometries

CNC machining excels at creating complex geometries in aluminum parts. You can depend on its ability to produce intricate designs repeatedly without compromising quality. Aluminum’s malleability complements CNC’s precision, allowing for the creation of detailed components. For example, aerospace applications often require structural brackets, body panels, and landing gear with precise dimensions.

Note: Industries like electronics and automotive also benefit from CNC’s ability to produce customized and intricate parts, such as heat sinks and engine blocks.

CNC machining ensures reproducible accuracy, which is critical for defense applications. Whether you need parts for military vehicles or advanced weaponry, CNC technology guarantees consistent results. This reliability makes it indispensable for manufacturing critical components with complex shapes.

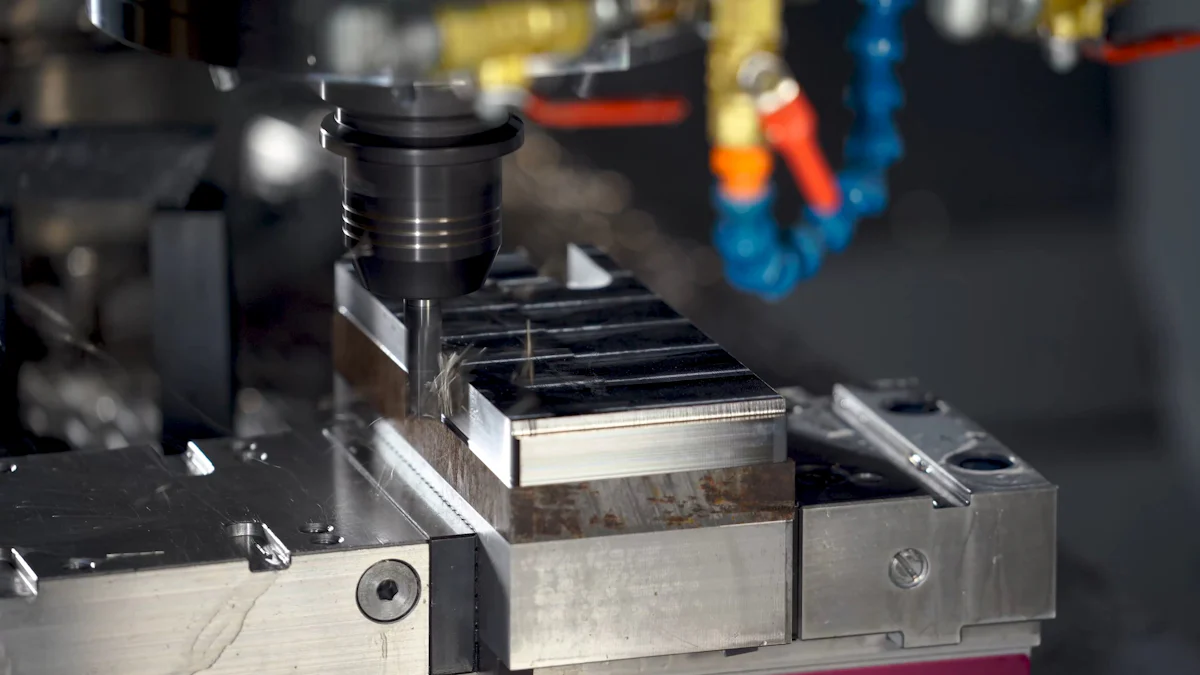

Efficiency in High-Volume Production

CNC machining improves efficiency in high-volume production of aluminum components. Aluminum’s excellent machinability reduces machining time, increasing productivity. You benefit from extended tool life, which lowers manufacturing costs. CNC machines operate continuously, producing large quantities of parts with consistent quality.

Tip: Aluminum’s lightweight nature also reduces shipping costs, enhancing economic efficiency in large-scale production.

CNC machining supports rapid prototyping, enabling you to develop new designs quickly. This is especially valuable in the defense sector, where innovation is constant. By combining speed, precision, and cost-effectiveness, CNC machining streamlines part production for military applications.

Advantages of CNC for Military Applications

Durability and Structural Integrity

CNC machining ensures the durability and structural integrity of military-grade aluminum parts. You can rely on its precision to achieve sub-micron tolerances, which are essential for high-performance tools. This level of accuracy guarantees that components meet strict military standards, even under extreme conditions. CNC technology allows you to create complex geometries, enabling the production of intricate designs necessary for advanced military equipment.

Parts manufactured through CNC machining undergo rigorous condition testing. These tests ensure that components can withstand harsh environments, such as extreme temperatures or battlefield conditions. For example, aluminum parts used in military vehicles and aircraft maintain their structural integrity during high-stress operations. The repeatability of CNC processes also ensures consistent quality across mass production, which is vital for maintaining reliability in military applications.

Tip: CNC machining combines precision and durability, making it indispensable for producing components that perform reliably in demanding scenarios.

Customization for Military Specifications

CNC technology excels at customization, allowing you to meet specific military requirements. Multi-axis CNC machining enables the creation of intricate and detailed parts for drones, tanks, and missiles. This adaptability ensures that components are tailored to enhance the performance of military equipment. For example, you can design parts with improved heat or impact resistance to withstand challenging environments.

Rapid prototyping is another advantage of CNC machining. You can quickly develop and test custom components, ensuring they meet operational demands. This capability is crucial for military projects, where innovation and adaptability are key. CNC machining also ensures mass production consistency, so every part adheres to the same high standards.

Note: Custom CNC machining allows you to create unique designs that improve the functionality and reliability of military systems.

Cost-Effectiveness in Military Manufacturing

CNC machining offers significant cost-saving benefits for military manufacturing. Its computerized controls enable high-speed operations, reducing production time without compromising quality. This efficiency minimizes waste, leading to lower manufacturing costs. You can achieve rapid production of aluminum parts while maintaining precision, which is essential for high-performance military equipment.

The durability of CNC-machined components also contributes to cost-effectiveness. Reliable parts reduce the need for frequent replacements, saving resources in the long term. Additionally, CNC machining supports both low-volume prototyping and high-volume production, making it a versatile solution for military projects.

Tip: By combining speed, precision, and efficiency, CNC machining ensures cost-effective manufacturing for military applications.

Real-World Examples of CNC in Military Manufacturing

CNC Machined Aircraft Components

CNC plays a vital role in producing high-precision components for military aircraft. You rely on this technology to manufacture rotor blades, gearboxes, and engine parts, all of which require exact tolerances and intricate geometries. For example, General Atomics used CNC machining in the development of the Predator aircraft. This drone, primarily constructed with carbon/epoxy prepregs, demonstrates how CNC integrates advanced materials into military applications.

Aluminum’s lightweight and corrosion-resistant properties make it ideal for aircraft structures. CNC machining ensures these aluminum components meet the rigorous demands of military operations. Whether crafting fuselage parts or landing gear, CNC delivers the precision and reliability you need for high-performance aircraft.

Weaponry and Ammunition Aluminum Parts

CNC machining is essential for producing precision components in firearms and ammunition. You depend on CNC to create parts like barrels, triggers, and receivers for weapons such as the AK47. These components must meet tight tolerances to ensure consistent performance under extreme battlefield conditions.

Missiles and bombs also benefit from CNC technology. Aluminum parts in these weapons enhance their operational effectiveness by reducing weight and improving structural integrity. CNC machining supports the production of radar systems, spacecraft, and warship components, ensuring high precision and reliability. This technology plays a pivotal role in maintaining the functionality of military hardware.

CNC in Military Vehicles and Naval Equipment

CNC machining is critical for creating components used in military vehicles and naval equipment. You can see its impact in the production of armored vehicles, where aluminum parts provide a balance of strength and weight. For example, CNC machines produce high-tolerance components like front grills for vehicles such as the Hummer H2.

In naval applications, CNC machining ensures warship components meet strict performance standards. Aluminum’s machinability allows for faster production of intricate designs, such as radar systems and hull structures. The precision of CNC machining guarantees that these parts perform reliably in extreme conditions, making it indispensable for military equipment.

Note: CNC machining achieves tolerances as low as a few microns, enabling the production of complex shapes and ensuring durability in demanding environments.

CNC machining stands as a cornerstone of military manufacturing, delivering precision and reliable performance in aluminum parts production. You benefit from its ability to create components with sub-micron tolerances, ensuring functionality in extreme conditions. The integration of advanced technologies like AI and robotics continues to enhance CNC processes, enabling rapid prototyping and customization for evolving defense needs. Aluminum’s lightweight and durable properties, combined with CNC’s efficiency, meet the rigorous demands of military applications. This synergy ensures high-quality components that strengthen defense capabilities while optimizing production for the future.

FAQ

What makes CNC machining essential for the defense industry?

CNC machining ensures precision and reliability in producing critical parts for the defense industry. You can depend on its ability to meet strict tolerances, which is vital for aerospace and defense applications. This technology guarantees consistent quality, making it indispensable for manufacturing components used in critical applications.

Why is aluminum widely used in aerospace and defense manufacturing?

Aluminum offers a high strength-to-weight ratio, corrosion resistance, and excellent machinability. These properties make it ideal for aerospace and defense applications. You benefit from its ability to enhance mobility in vehicles and aircraft while maintaining durability, ensuring reliable performance in critical applications.

How does CNC machining improve efficiency in aerospace and defense production?

CNC machining automates processes, reducing production time and minimizing errors. You can achieve high-volume production of critical parts with consistent quality. This efficiency supports rapid prototyping and customization, which are essential for meeting the evolving demands of the defense industry.

Can CNC machining handle complex geometries for aerospace components?

Yes, CNC machining excels at creating intricate designs and complex geometries. You can rely on its precision to produce aerospace components like airfoils and landing gear. This capability ensures that parts meet the exact specifications required for critical applications in aerospace and defense.

What role do advanced CNC machining services play in defense manufacturing?

Advanced CNC machining services provide the precision and customization needed for defense manufacturing. You can create components tailored to specific military requirements. These services ensure that critical parts meet the rigorous standards of aerospace and defense, enhancing the performance and reliability of military equipment.

See Also

Achieving Precision in CNC Machining for Parts Production

Expert CNC Milling Techniques for High-Precision Parts

Streamlined CNC Machining Solutions for Precision Production

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com