How to Select the Right CNC Machining Service

Selecting the right CNC machining supplier is a pivotal decision with far-reaching implications. This blog will delve into the intricacies of choosing wisely, ensuring your projects are in capable hands. Making an informed choice not only guarantees precision and quality but also optimizes costs and production efficiency. By understanding the nuances of CNC hardware, CNC milling, CNC CUSTOM parts, and CNC service offered by suppliers, you pave the way for seamless operations and exceptional outcomes.

Understanding CNC Machining Services

When considering CNC machining services, it's essential to grasp the significance of this advanced manufacturing method. CNC machining involves utilizing computer-controlled machinery to craft precise components with unparalleled accuracy and efficiency. This technology finds widespread applications across diverse industries, including aerospace, medical, and automotive sectors.

What is CNC Machining?

Definition and basic principles

CNC machining stands for Computer Numerical Control machining, a process that automates tool operation through computer commands. The fundamental principle revolves around transforming digital designs into physical products with exceptional precision. This method replaces traditional manual operations with automated processes, enhancing speed and accuracy in part production.

Common applications and industries

The versatility of CNC machining extends to various applications such as creating housings, enclosures, brackets, fixtures, gears, bearings, and internal components. Industries like aerospace, medical instrumentation, automotive manufacturing rely heavily on CNC machining for its ability to deliver intricate parts with consistent quality.

Types of CNC Machining Services

Milling

CNC milling involves removing material from a workpiece using rotary cutters to achieve the desired shape. This process is ideal for creating complex geometries and producing components with tight tolerances. The precision offered by CNC milling makes it a preferred choice for intricate part manufacturing.

Turning

In CNC turning, the workpiece rotates while cutting tools remove material to create cylindrical shapes. This process is commonly used for producing shafts, pins, and other rotational parts. CNC turning enables efficient mass production of symmetrical components with high accuracy.

Drilling

CNC drilling focuses on creating holes in workpieces using specialized drill bits controlled by computer programs. This service is crucial for various industries requiring precise hole placement and consistent boring operations. CNC drilling ensures uniformity and accuracy in hole dimensions.

Other specialized services

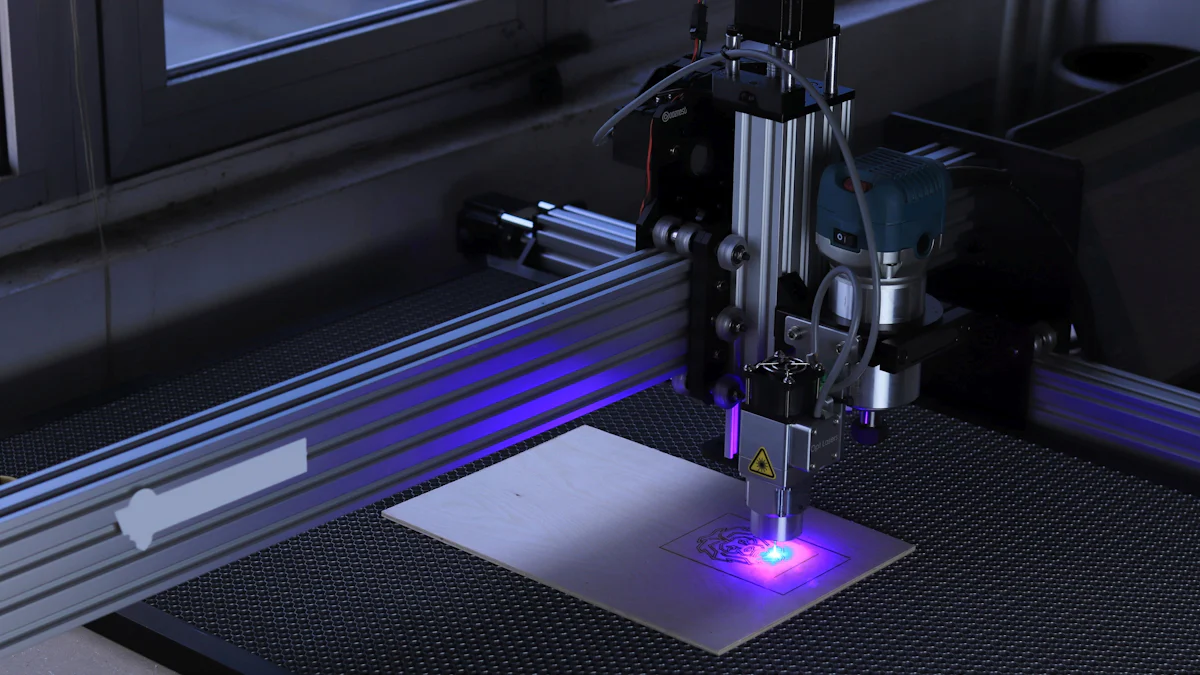

Apart from milling, turning, and drilling, CNC machining suppliers offer a range of specialized services tailored to specific industry needs. These may include wire EDM (Electrical Discharge Machining), laser cutting, plasma cutting, or waterjet cutting services depending on the material requirements and project specifications.

Key Factors to Consider

When evaluating CNC hardware, CNC milling, CNC CUSTOM parts, and CNC service providers, it is imperative to prioritize key factors that directly impact the quality and precision of your projects. By focusing on aspects such as tolerances, accuracy, material capabilities, industry experience, technical expertise, state-of-the-art machinery, and software tools used by suppliers, you ensure optimal outcomes for your manufacturing needs.

Quality and Precision

Tolerances and accuracy

Achieving precise tolerances and high accuracy levels is essential for intricate component production.

Ensuring that the CNC machining supplier can meet your specific dimensional requirements guarantees quality outcomes.

Greater design freedom allows for complex geometries with finer features compared to conventional machining methods.

Material capabilities

Understanding the material capabilities of a CNC machining service provider is crucial for selecting the right partner.

Higher accuracy in part production enables the creation of components with superior surface finishes and detailed features.

The availability of a wide range of materials ensures compatibility with diverse project requirements.

Experience and Expertise

Industry experience

Partnering with a CNC machining supplier that has extensive industry experience enhances project efficiency.

Leveraging the supplier's knowledge of industry-specific standards ensures compliance with quality regulations.

Rapid prototyping commitment accelerates product development cycles for faster time-to-market advantages.

Technical expertise

Technical expertise in CNC machining processes guarantees efficient production workflows and optimized lead times.

Continuous improvement initiatives drive innovation within the manufacturing process for enhanced product quality.

Effective communication channels foster collaboration between clients and suppliers for seamless project execution.

Technology and Equipment

State-of-the-art machinery

Investing in state-of-the-art machinery reflects a commitment to delivering high-quality machined parts.

The utilization of advanced equipment enhances production capacity to meet varying project demands efficiently.

Higher precision levels achieved through modern technology result in superior part performance and functionality.

Software and tools used

Employing cutting-edge software tools streamlines design-to-production workflows for increased operational efficiency.

Enhanced software capabilities enable complex part programming for intricate component manufacturing.

Integration of advanced tools optimizes toolpath generation, reducing cycle times while maintaining precision levels.

Cost and Budget

Pricing models

CNC machining services offer various pricing models to cater to different project requirements, ensuring cost-effectiveness and flexibility in budget allocation.

Fixed pricing structures provide clarity on costs from the outset, allowing for better financial planning and transparency in transactions.

Customized pricing options enable tailored solutions based on project complexities, ensuring that you pay for the services you truly need.

Hidden costs and additional fees

Transparency regarding hidden costs and additional fees is crucial when selecting a CNC machining supplier, preventing unexpected financial burdens down the line.

Understanding the breakdown of costs associated with tooling, setup, materials, and post-processing ensures accurate budget estimations.

Clear communication on potential extra charges for rush orders or design modifications helps in avoiding surprises during project execution.

Turnaround Time

Lead times

Efficient lead times are paramount in CNC machining services, facilitating timely project completion and meeting critical deadlines without compromising quality.

Streamlined production processes minimize lead times, ensuring swift turnaround from design to finished parts.

Reliable scheduling mechanisms optimize lead times by balancing workload capacities with client demands effectively.

Rush services availability

The availability of rush services with CNC machining suppliers offers expedited manufacturing solutions for urgent projects requiring quick turnaround times.

Prioritizing rush orders through dedicated resources and accelerated workflows guarantees prompt delivery without sacrificing precision or quality standards.

Flexible production schedules accommodate rush service requests, demonstrating a commitment to meeting client needs promptly.

Reliability

Supplier reputation

A CNC machining supplier's reputation is a testament to their reliability and performance consistency, reflecting their ability to deliver quality results consistently.

Positive customer reviews and testimonials validate the supplier's reputation for excellence in service delivery and product quality.

Established relationships with reputable clients underscore the supplier's trustworthiness and commitment to customer satisfaction.

Consistency in delivery

Consistent delivery of high-quality machined parts underscores a CNC machining supplier's reliability in meeting client expectations consistently.

Adherence to strict quality control measures ensures consistent part accuracy and surface finish across all projects undertaken by the supplier.

On-time deliveries showcase the supplier's commitment to reliability, instilling confidence in clients regarding project timelines.

Material Selection and Availability

Types of materials offered

CNC machining suppliers provide a diverse range of materials to cater to various project requirements, ensuring flexibility and compatibility with different industry needs.

Aluminum, steel, titanium, and plastics are among the commonly offered materials, each possessing unique properties that influence part performance and functionality.

The availability of specialized materials such as composites or exotic alloys expands design possibilities and enables the creation of components for specialized applications.

Material sourcing and availability

CNC machining suppliers prioritize sourcing materials from reputable vendors to guarantee quality and consistency in part production.

Establishing strategic partnerships with material suppliers ensures timely access to raw materials, minimizing production delays and project disruptions.

Maintaining a well-managed inventory of materials enhances operational efficiency, allowing for quick response times to client demands and rapid project turnaround.

Evaluating Potential CNC Machining Services

When assessing potential CNC machining suppliers, thorough research and reviews play a pivotal role in ensuring optimal service selection. Online reviews and testimonials provide valuable insights into the supplier's performance and customer satisfaction levels, guiding decision-making processes effectively.

Research and Reviews

Online reviews offer firsthand experiences shared by previous clients, highlighting service quality, reliability, and overall satisfaction levels.

Testimonials showcase successful collaborations, emphasizing the supplier's capabilities, professionalism, and commitment to meeting client expectations.

Case studies present real-world applications of CNC machining services, demonstrating expertise, project outcomes, and problem-solving abilities in diverse manufacturing scenarios.

Certifications and standards further validate a CNC machining supplier's commitment to excellence and adherence to industry best practices. ISO certifications signify quality management systems compliance, ensuring consistent service delivery and product quality benchmarks.

Certifications and Standards

ISO certifications demonstrate a supplier's dedication to maintaining high-quality standards throughout their operations, guaranteeing precision, reliability, and customer-centric service approaches.

Industry-specific standards underscore a supplier's specialization in catering to unique industry requirements with tailored solutions that align with regulatory frameworks.

Effective communication channels are essential for seamless project execution and client satisfaction. Responsiveness from the supplier ensures timely updates on project progress, addressing queries promptly while fostering strong partnerships built on trust and transparency.

Communication and Customer Service

Responsiveness reflects a supplier's commitment to client needs by offering timely feedback, updates on project milestones, and proactive communication channels for enhanced collaboration.

Support services encompass after-sales assistance, troubleshooting support, and ongoing maintenance guidance to ensure long-term success post-project completion.

Making the Final Decision

Comparing Options

Pros and cons list

Evaluate the strengths and weaknesses of each CNC machining supplier meticulously.

Consider factors like quality, reliability, pricing, and customer service in your assessment.

Highlight the key advantages and drawbacks to make an informed decision that aligns with your project requirements.

Decision matrix

Create a structured matrix outlining essential criteria for selecting a CNC machining service.

Assign weightage to each criterion based on its significance to your project goals.

Score potential suppliers against these criteria to objectively compare their offerings.

Use the decision matrix as a visual aid to streamline your selection process and identify the most suitable partner.

Requesting Quotes and Proposals

What to include in an RFQ (Request for Quote)

Specify detailed project requirements, including material preferences, tolerances, and quantities.

Clearly outline any surface treatment or finishing specifications needed for your components.

Provide CAD files or technical drawings to facilitate accurate quoting and proposal generation.

Evaluating proposals

Scrutinize each proposal for adherence to your stated requirements and quality standards.

Compare pricing structures, lead times, and additional services offered by different suppliers.

Seek clarification on any ambiguous points or discrepancies in the proposals before making a final decision.

Summarize the importance of meticulous supplier selection to ensure project success.

Encourage readers to act decisively and choose CNC machining services wisely.

Trust in reputable suppliers like Penta Precision and New CNC for top-notch quality and service excellence.

Take inspiration from satisfied customers who praise the expertise and reliability of CNC Engineering.

Make your choice today for precision, efficiency, and exceptional results.

See Also

Discovering Precision Manufacturing with CNC Machining Services

Streamlined Precision Manufacturing through CNC Machining Services

Perfecting Precision Parts Manufacturing with CNC Machining

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com