Texturing Aluminum Surfaces for Better Aesthetics using CNC Machining

CNC machining offers a precise way to enhance aluminum surfaces, combining functionality with aesthetic appeal. You can achieve intricate textures that elevate the look and feel of aluminum products. Industries like aerospace, automotive, electronics, and medical devices rely on textured aluminum for its durability and visual impact. This aluminum surface treatment not only improves aesthetics but also adds practical value, such as better grip or light diffusion. Whether for branding or functionality, CNC ensures consistent and high-quality results.

Key Takeaways

CNC machining helps create detailed textures on aluminum surfaces.

These textures make aluminum look better and work more effectively.

Textured aluminum improves grip and spreads light, making it safer.

CNC machining lets companies design aluminum to match their brand.

This makes their products unique and better for competition.

Why Texture Aluminum Surfaces?

Enhancing Visual Appeal

Texturing aluminum surfaces significantly enhances their aesthetic value, making them suitable for a wide range of applications. You can achieve various aluminum surface finishes, such as brushed, polished, or anodized aluminum, to create the desired visual appearance. Brushed aluminum provides a sleek, modern look, while polished aluminum offers high reflectivity, adding a luxurious appeal. These finishes are ideal for products where both style and functionality matter.

Real-world examples demonstrate how textured aluminum transforms designs. For instance, the Seattle Central Library features irregularly patterned aluminum cladding that reflects light dynamically. Similarly, the Walt Disney Concert Hall uses sweeping forms of reflective aluminum to create mesmerizing light play. These examples highlight how aluminum surface treatment can elevate architectural and product designs.

Branding and Customization

Textured aluminum surfaces allow you to customize products to align with your brand identity. CNC machining enables precise engraving or etching of logos, patterns, or unique designs onto aluminum parts. This level of customization ensures your products stand out in competitive markets. Whether you aim for a minimalist design or intricate detailing, aluminum surface treatment offers endless possibilities to achieve your branding goals.

Functional Benefits (e.g., grip, light diffusion)

Beyond aesthetics, textured aluminum surfaces provide practical advantages. Textures improve grip, making aluminum parts safer and easier to handle. For example, knurled finishes enhance the usability of tools and handles. Additionally, treatments like anodizing or powder coating improve durability and resistance to wear. Textured surfaces also diffuse light effectively, reducing glare and enhancing visibility in specific applications. These functional benefits make aluminum surface finishes a preferred choice across industries.

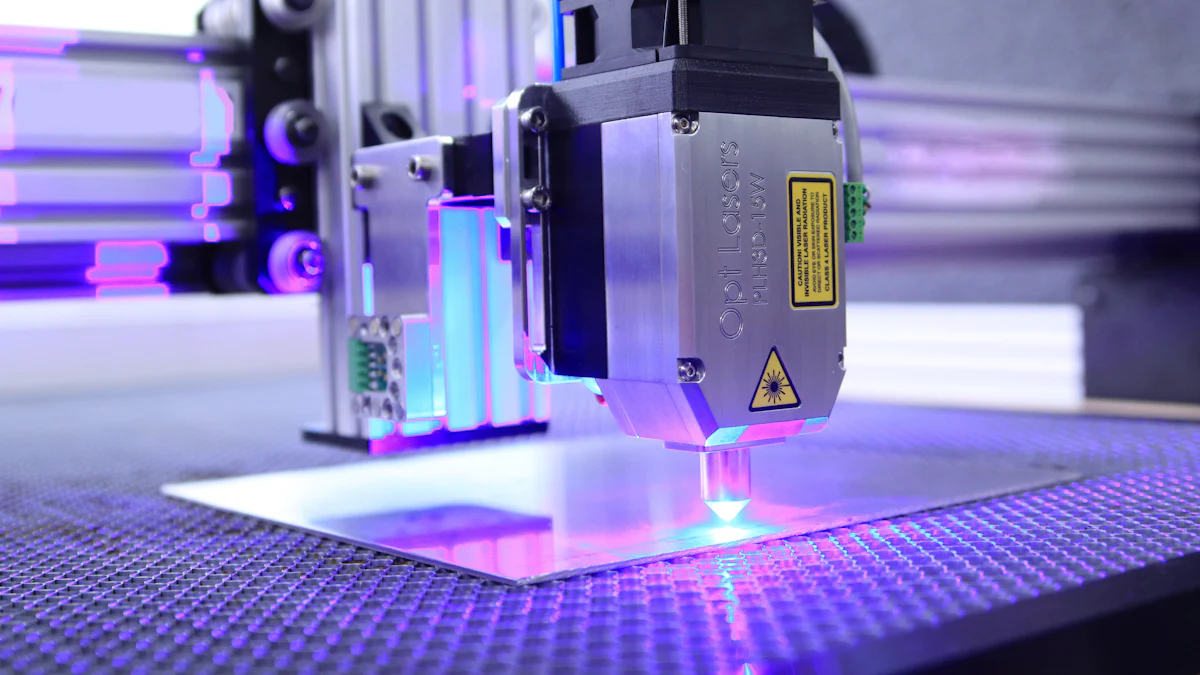

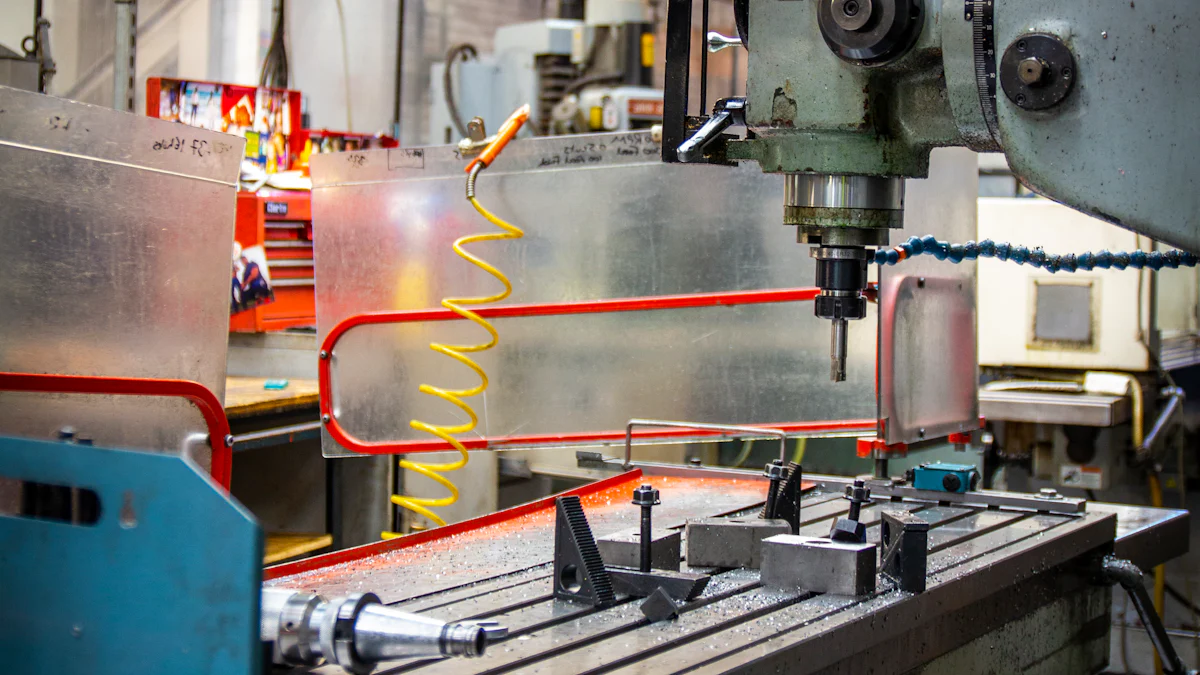

CNC Machining Techniques for Texturing Aluminum

Engraving

Engraving is one of the most precise CNC machining techniques for texturing aluminum surfaces. This method allows you to create intricate designs, logos, or text on aluminum parts with exceptional accuracy. Industries such as aerospace, automotive, and electronics often rely on engraving for branding or part identification. For example, you can use this technique to mark serial numbers or logos, ensuring traceability and enhancing your brand's visibility. The high precision of CNC engraving machines makes it ideal for producing detailed patterns that elevate the aesthetic appeal of aluminum finishes.

Bead Blasting

Bead blasting is a versatile aluminum surface treatment that creates a smooth, matte finish while removing contaminants. This technique involves propelling fine spherical beads at high speeds onto the aluminum surface. The impact forms tiny dimples that scatter light, resulting in a uniform satin-like appearance. Bead blasting is widely used for surface cleaning and finishing in manufacturing, PCB cleaning in electronics, and even artistic applications. It enhances the smoothness of aluminum surfaces, making them visually appealing and ready for further treatments like anodizing or powder coating.

Micro-Milling

Micro-milling offers unparalleled precision for creating fine textures on aluminum surfaces. This CNC machining technique uses specialized tools to carve intricate patterns or grooves into the material. You can achieve highly detailed textures that add both aesthetic and functional value. For instance, micro-milling is perfect for creating light-diffusing patterns or enhancing grip on aluminum parts. Its ability to produce consistent and repeatable designs makes it a preferred choice for industries requiring high-quality aluminum surface finishes.

Knurling and Surface Etching

Knurling and surface etching are two distinct techniques for texturing aluminum, each offering unique outcomes. Knurling deforms the aluminum surface to create grooves or bumps, improving grip and tactile feel. This makes it ideal for tools, handles, and other parts requiring enhanced friction. Surface etching, on the other hand, removes material to create intricate designs, focusing more on aesthetics. The table below highlights the key differences between these techniques:

Feature | Knurling | Surface Etching |

|---|---|---|

Technique | Deforms material to create a pattern | Removes material to create a design |

Purpose | Enhances grip and tactile feel | Primarily aesthetic |

Texture Outcome | Grooves and bumps for friction | Varies based on design, typically smoother |

Tooling | Uses a hardened roller tool | Uses various cutting and etching tools |

Both methods contribute to the versatility of aluminum surface finishes, allowing you to achieve the desired balance between functionality and aesthetic appeal.

Benefits of Using CNC Machining for Texturing

Precision and Accuracy

CNC machining offers unmatched precision when texturing aluminum surfaces. The process uses computer-controlled tools to remove material with exceptional accuracy, enabling the creation of intricate patterns and smooth finishes. Techniques like CNC milling and engraving allow you to achieve fine details, such as logos or complex geometries, on aluminum parts. For harder aluminum alloys, CNC Electrical Discharge Machining (EDM) provides a reliable solution for crafting intricate shapes. This level of precision ensures that your aluminum surface finishes meet both functional and aesthetic requirements without the need for extensive post-processing.

Repeatability for Consistent Results

CNC machining ensures consistent results across multiple aluminum parts, making it ideal for industries requiring uniformity. Whether you are producing components for aerospace, automotive, electronics, or medical devices, CNC machining guarantees repeatable quality. For example, the aerospace industry relies on CNC machining to create lightweight yet durable aluminum fittings, while the electronics sector uses it for protective housings with precise textures. This repeatability not only enhances the appeal of aluminum finishes but also ensures reliability in critical applications.

Customization for Unique Designs

CNC machining empowers you to create unique and customized designs for aluminum surfaces. Multi-axis CNC machines and advanced CAD software enable the production of complex geometries, such as curved surfaces and angled edges. Aluminum’s malleability further enhances its suitability for intricate designs. Whether you need tailored patterns for consumer electronics or detailed textures for automotive components, CNC machining provides the flexibility to meet your specific requirements. This customization capability allows you to align aluminum surface treatment with your brand identity or functional needs.

Scalability for Large or Small Projects

CNC machining is highly scalable, accommodating both large-scale production and small-batch projects. Its flexibility allows you to adjust production schedules and meet tight deadlines without compromising quality. For instance, CNC machining supports rapid prototyping for new designs while also handling high-volume manufacturing with consistent results. Additional services like anodizing and powder coating further enhance scalability by providing ready-to-use aluminum finishes. By choosing CNC machining, you can efficiently manage projects of any size while maintaining cost-effectiveness and quality.

Practical Considerations

Material Properties of Aluminum

Aluminum's unique properties make it an excellent choice for CNC machining and texturing. Its machinability allows you to achieve precise cuts without deformation, ensuring high-quality results. The material's strength-to-weight ratio makes it ideal for lightweight yet durable components in industries like aerospace and automotive. Aluminum also resists corrosion and scratching, which can be further enhanced through anodizing. This treatment not only improves durability but also adds aesthetic appeal to the surface. Additionally, aluminum performs well in low temperatures and offers high electrical conductivity, making it suitable for electronic parts. Its recyclability reduces waste and energy costs, making it an environmentally friendly option. Popular grades like 6061 and 7075 aluminum provide versatility and strength for various applications, while 5052 and 3003 aluminum excel in corrosion resistance and formability.

Design Limitations and Feasibility

While CNC machining offers precision, certain design features can pose challenges. Internal features or undercuts may be difficult to access, limiting the feasibility of some designs. Thin walls and sharp corners can also complicate machining, potentially leading to material deformation or breakage. Achieving specific textures, such as glossy or mirror-like finishes, may require additional post-processing like polishing or powder coating. Understanding these limitations helps you design aluminum parts that balance complexity with manufacturability, ensuring optimal results.

Cost-Effectiveness and Budget Planning

CNC machining textured aluminum surfaces can be cost-effective when you plan strategically. Using standardized components eliminates the need for custom tooling, reducing expenses. Aluminum itself is an affordable material that offers excellent suitability for machining and texturing. Batch production further optimizes costs by spreading fixed expenses over larger quantities. By carefully selecting materials and production methods, you can achieve high-quality aluminum surface finishes while staying within budget.

Maintenance and Durability of Textured Surfaces

Proper maintenance ensures the durability of CNC-machined textured aluminum surfaces. Regular cleaning of equipment, such as tanks used in anodizing, maintains process efficiency and consistency. Anodizing creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion and wear. This treatment also improves the appearance and longevity of the surface, making it a preferred choice for durable finishes. Incorporating these practices into your maintenance routine helps preserve the quality and appeal of anodized aluminum parts over time.

CNC machining offers a reliable way to achieve textured aluminum surfaces with both functional and aesthetic benefits. Its precision ensures intricate designs, while repeatability guarantees consistent results across parts. You can also customize textures to align with your brand or application needs.

To maximize results, consider these key takeaways:

Aluminum's corrosion resistance reduces replacement frequency.

Lightweight parts lower shipping costs.

Durable finishes minimize long-term expenses.

Benefit | Description |

|---|---|

Improved Surface Finish | Ensures the part’s surface is ready for anodizing, leading to a more uniform and durable finish. |

Enhanced Appearance | Anodizing provides a decorative finish, useful for parts that require both functionality and aesthetics. |

Post-Processing Services | Essential for improving surface finish or adding protective coatings like powder coating or anodizing. |

Deburring | Removes sharp edges or burrs, enhancing safety and aesthetics. |

Anodizing | Increases corrosion and wear resistance while improving appearance and durability. |

Choosing the right aluminum alloy and optimizing designs can further enhance results. CNC technology reduces production time and errors, making aluminum a cost-effective choice for manufacturing. By addressing material properties, design constraints, and costs, you can achieve superior aluminum finishes tailored to your needs.

FAQ

What is the best aluminum grade for CNC texturing?

6061 and 7075 aluminum are excellent choices. They offer strength, machinability, and corrosion resistance, making them ideal for precise CNC texturing applications.

How do you maintain textured aluminum surfaces?

Clean regularly with mild soap and water. Avoid abrasive cleaners. Anodized finishes enhance durability and reduce maintenance needs for textured aluminum parts.

Can CNC machining handle complex aluminum designs?

Yes, multi-axis CNC machines can create intricate patterns and geometries. Advanced CAD software ensures precise execution of even the most complex designs.

💡 Tip: Always consult with your CNC machining provider to select the right aluminum grade and finish for your project.

See Also

Benefits of Utilizing CNC Machining Services for Aluminum

Key Strategies for Achieving Scratch-Free Aluminum CNC Machining

CNC Machining Process and Uses of Aluminum Alloy 7075

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com