Top 10 CNC Machine Problems and How to Solve Them

CNC machines revolutionize manufacturing with precise and automated control. These machines enhance efficiency and meet the growing demand for high-precision products. However, CNC machines often face common issues that disrupt operations. Frequent problems arise due to code errors, lack of maintenance, and mechanical failures. Understanding these challenges is crucial for maintaining optimal performance. This blog aims to equip you with practical solutions to address these common CNC machine problems effectively.

CNC Machine Problem 1: Machine Vibration

Causes of Machine Vibration in CNC Machines

Machine vibration often disrupts the precision of a CNC machine. Imbalance in the machine components can lead to significant vibration. Components that are not evenly distributed cause this issue. Loose parts or connections also contribute to vibration. These loose elements create instability during operation.

Solutions to Reduce Vibration in CNC Machines

Regular maintenance and inspection play a crucial role in minimizing vibration. Scheduled checks help identify imbalances early. Technicians can address these issues before they escalate. Balancing machine components is another effective solution. Proper alignment ensures smooth operation of the CNC machine.

Case Studies:

Vibrations Diagnostics for Maintenance Planning: Diagnosing vibrations prevents machine damage. This approach improves maintenance strategies.

Vibration Analysis for Predictive Maintenance: Predictive analysis identifies problems early. This method helps avoid unexpected failures.

Routine maintenance and balancing enhance the performance of a CNC machine. These practices ensure longevity and efficiency. Implementing these solutions reduces operational disruptions.

CNC Machine Problem 2: Overheating

Causes of Overheating in CNC Machines

Overheating poses a significant threat to the efficiency of any CNC machine. An inadequate cooling system often leads to overheating. Cooling systems must function properly to dissipate heat generated during operations. Excessive load on the machine also contributes to overheating. Continuous high-volume machining without breaks increases the risk of overheating.

Scientific Research Findings:

CNC Machine Maintenance Can Prevent Overheating: Regular maintenance keeps machines clean and lubricated, preventing overheating.

7 Common Issues in Setup and Maintenance of CNC Machines and Ways to Fix Them: Machines should not exceed 150 degrees to avoid overheating.

Solutions to Prevent Overheating in CNC Machines

Upgrading the cooling system is essential for preventing overheating. Modern cooling systems provide efficient heat dissipation. Monitoring machine load and operation time helps manage overheating risks. Operators should avoid running machines at the highest RPM continuously. Regular breaks during prolonged machining sessions reduce heat buildup.

Practical Tips:

Install advanced cooling systems for better temperature control.

Schedule routine checks to ensure cooling systems work effectively.

Use sensors to monitor temperature and load in real-time.

Maintaining optimal temperatures ensures the longevity and performance of a CNC machine. Implementing these solutions minimizes downtime and enhances productivity.

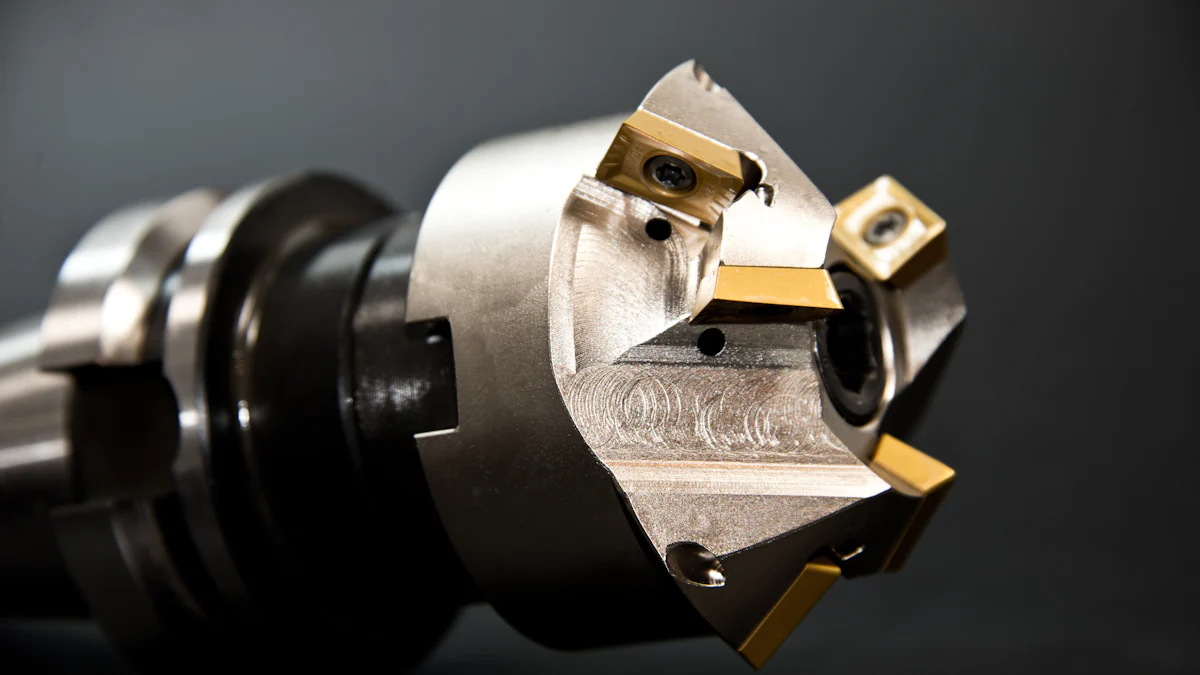

CNC Machine Problem 3: Tool Wear

Tool wear presents a significant challenge in CNC machining. Operators often encounter this issue, which affects the quality of the finished product and increases production costs. Understanding the causes of tool wear helps in implementing effective solutions.

Causes of Tool Wear in CNC Machines

Poor Quality Tools

Using poor quality tools leads to rapid wear and tear. Low-grade materials lack the durability needed for high-speed machining. Inferior tools often break or dull quickly, causing disruptions in the manufacturing process. Selecting tools made from high-quality materials ensures better performance and longevity.

Incorrect Tool Usage

Incorrect usage of tools accelerates wear. Operators sometimes use tools beyond their intended capacity. This misuse results in excessive friction and heat, damaging the tool. Proper training on tool usage prevents these issues. Operators must understand the specifications and limitations of each tool used in a CNC machine.

Solutions to Minimize Tool Wear in CNC Machines

Using High-Quality Tools

Investing in high-quality tools reduces wear significantly. Tool Selections for CNC Machining emphasizes choosing tools with appropriate materials and coatings. These selections enhance durability and cutting efficiency. Opting for tools with suitable geometry also prevents common CNC machine problems related to materials breaking and burning.

Proper Tool Maintenance and Usage

Routine maintenance practices extend tool life. Routine Tool Maintenance highlights the importance of monitoring tool wear. Operators should measure wear regularly and replace worn tools promptly. Implementing proper maintenance practices ensures efficient machining and high part quality. Training operators in correct tool usage further minimizes wear. Understanding tool specifications and adhering to recommended usage guidelines prevent unnecessary damage.

Practical Tips:

Choose tools made from durable materials.

Train operators on proper tool usage and maintenance.

Monitor tool wear and replace tools as needed.

Implementing these solutions enhances the performance of a CNC machine. Reducing tool wear improves the quality and consistency of manufactured parts. These practices contribute to the overall efficiency and cost-effectiveness of CNC machining operations.

CNC Machine Problem 4: Inaccurate Cutting

Inaccurate cutting often disrupts the precision of a CNC machine. This problem affects the quality of the final product. Understanding the causes helps in finding effective solutions.

Causes of Inaccurate Cutting in CNC Machines

Calibration Issues

Calibration issues frequently lead to inaccurate cutting in CNC machines. Regular calibration is vital for maintaining accuracy. Incorrect calibration settings cause deviations in the cutting process. Routine calibration ensures greater accuracy and reduces errors.

Software Errors

Software errors also contribute to inaccurate cutting. Outdated software or glitches affect the machine's performance. These errors disrupt the synchronization between the software and the CNC machine. Regular software updates help maintain optimal performance.

Solutions for Accurate Cutting in CNC Machines

Regular Calibration of the Machine

Regular calibration of the CNC machine is crucial. Calibration aligns the machine components accurately. This practice ensures precision in every cut. Scheduled calibration checks identify potential issues early. Technicians can address these problems before they affect production.

Updating and Checking Software

Updating and checking software is essential for accurate cutting. Software updates fix bugs and improve functionality. Operators should regularly check for updates and install them promptly. Compatibility checks prevent software-related disruptions. Ensuring the software works seamlessly with the CNC machine enhances accuracy.

Practical Tips:

Schedule regular calibration sessions.

Monitor calibration settings closely.

Keep software updated to the latest version.

Conduct compatibility checks before installing updates.

Implementing these solutions enhances the precision of a CNC machine. Accurate cutting improves the quality and consistency of manufactured parts. These practices contribute to the overall efficiency and reliability of CNC machining operations.

CNC Machine Problem 5: Power Supply Issues

Causes of Power Supply Issues in CNC Machines

Fluctuating Power Supply

Fluctuating power supply often disrupts CNC machine operations. Inconsistent voltage levels cause machines to malfunction. Voltage spikes or drops lead to unexpected shutdowns. These fluctuations damage sensitive components.

Faulty Wiring

Faulty wiring presents another challenge for CNC machines. Poorly installed wires create electrical hazards. Loose connections result in intermittent power loss. Damaged wires increase the risk of short circuits.

Solutions to Ensure Stable Power Supply in CNC Machines

Installing Voltage Stabilizers

Installing voltage stabilizers helps maintain consistent power levels. Stabilizers regulate incoming voltage to prevent fluctuations. These devices protect CNC machines from sudden power changes. Consistent voltage ensures smooth machine operation.

Regular Electrical Inspections

Regular electrical inspections identify potential wiring issues. Technicians check for loose connections and damaged wires. Early detection prevents major electrical problems. Routine inspections enhance machine safety and reliability.

Practical Tips:

Install high-quality voltage stabilizers.

Schedule regular electrical inspections with qualified technicians.

Monitor power supply consistency using reliable equipment.

Implementing these solutions ensures a stable power supply for CNC machines. Reliable power enhances machine performance and reduces downtime. Proper electrical management contributes to efficient manufacturing processes.

CNC Machine Problem 6: Software Glitches

Causes of Software Glitches in CNC Machines

Outdated Software

Outdated software often causes glitches in CNC machines. Software updates provide essential improvements and bug fixes. Ignoring updates leads to performance issues. Operators must ensure the software remains current.

Incompatible Software Updates

Incompatible software updates disrupt CNC machine operations. Updates must align with existing systems. Installing incompatible versions causes errors. Operators should verify compatibility before proceeding with updates.

Solutions to Fix Software Glitches in CNC Machines

Regular Software Updates

Regular software updates prevent glitches. Updates enhance functionality and resolve known issues. Operators should schedule routine checks for new versions. Prompt installation ensures optimal machine performance.

Compatibility Checks Before Updates

Compatibility checks before updates are crucial. Operators must confirm that updates match system requirements. This practice avoids potential disruptions. Reliable operation depends on careful verification.

Expert Testimony:

CNC Machine Professionals emphasize the importance of a systematic approach to troubleshooting. Regular updates and compatibility checks form part of this strategy. Proper maintenance ensures long-lasting machine reliability.

Implementing these solutions minimizes software-related problems. Consistent updates and compatibility checks maintain CNC machine efficiency. These practices contribute to smooth and uninterrupted operations.

CNC Machine Problem 7: Mechanical Failures

Causes of Mechanical Failures in CNC Machines

Wear and Tear of Components

CNC machines often experience wear and tear due to continuous operation. Components degrade over time, leading to mechanical failures. Frequent use without proper care accelerates this process. Operators must remain vigilant about the condition of machine parts.

Lack of Lubrication

Lack of lubrication causes friction between moving parts. Friction generates heat, which damages components. Proper lubrication reduces wear and extends the life of the machine. Operators should ensure that lubrication schedules are strictly followed.

Solutions to Prevent Mechanical Failures in CNC Machines

Routine Maintenance and Part Replacement

Routine maintenance identifies worn components early. Regular checks prevent unexpected breakdowns. Technicians should replace parts before they fail. Scheduled maintenance ensures the machine operates efficiently.

Key Steps for Maintenance:

Inspect all components regularly.

Replace parts showing signs of wear.

Document maintenance activities for future reference.

Ensuring Proper Lubrication

Proper lubrication minimizes friction and heat. Operators should follow a strict lubrication schedule. Use the recommended lubricants for each component. Regular lubrication checks prevent mechanical failures.

Lubrication Tips:

Apply lubricants according to manufacturer guidelines.

Monitor lubricant levels frequently.

Use high-quality lubricants for better performance.

Implementing these solutions reduces mechanical failures in CNC machines. Consistent maintenance and lubrication enhance machine reliability. These practices contribute to efficient and uninterrupted operations.

CNC Machine Problem 8: Poor Surface Finish

Causes of Poor Surface Finish in CNC Machines

Incorrect Cutting Parameters

Incorrect cutting parameters often lead to poor surface finishes. Operators must choose the right speed and feed rate for each material. Inappropriate settings cause rough or uneven surfaces. Precision in parameter selection ensures smooth finishes.

Tool Wear

Tool wear significantly affects surface quality. Worn tools create imperfections on the workpiece. Regular use without inspection leads to dull edges. Dull tools increase friction and degrade surface finish.

Solutions for Better Surface Finish in CNC Machines

Optimizing Cutting Parameters

Optimizing cutting parameters improves surface quality. Operators should adjust speed and feed rates based on material properties. Testing different settings helps find the optimal combination. Consistent parameter checks maintain high-quality finishes.

Regular Tool Inspection and Replacement

Regular tool inspection prevents surface defects. Operators should examine tools for wear before each use. Replacing worn tools ensures clean cuts and smooth surfaces. Routine inspections extend tool life and enhance machining quality.

Testimonials:

CNC Machining Expert: Our collaboration with trusted supply chain partners and the valuable insights we gain from customer testimonials are integral to our continuous improvement and dedication to minimizing CNC machining defects.

Implementing these solutions enhances the surface finish of CNC-machined parts. Proper cutting parameters and tool maintenance ensure superior product quality. These practices contribute to efficient and reliable manufacturing processes.

CNC Machine Problem 9: Excessive Noise

Causes of Excessive Noise in CNC Machines

Loose Components

Loose components often cause excessive noise in CNC machines. Vibrations occur when parts are not tightly secured. These vibrations generate loud sounds during operation. Regular checks can identify and fix loose components.

Worn-out Bearings

Worn-out bearings contribute to noise issues in CNC machines. Bearings support moving parts and reduce friction. Wear and tear on bearings lead to increased noise levels. Inspecting bearings regularly helps detect wear early.

Solutions to Reduce Noise in CNC Machines

Tightening and Securing Components

Tightening and securing components reduce noise effectively. Ensure all parts are firmly attached before starting the machine. Use appropriate tools to tighten bolts and screws. Regular maintenance checks prevent components from loosening.

Replacing Worn-out Bearings

Replacing worn-out bearings minimizes noise in CNC machines. New bearings provide smooth operation and reduce friction. Choose high-quality bearings for better performance. Schedule regular inspections to identify worn bearings promptly.

CNC Machine Problem 10: Chip Control Issues

Causes of Chip Control Issues in CNC Machines

Inadequate Chip Removal System

CNC machines often face chip control issues due to inadequate removal systems. Inefficient systems fail to clear chips from the work area. Accumulated chips can damage the machine and affect product quality. Operators must ensure that chip removal systems function effectively.

Incorrect Cutting Speed

Incorrect cutting speed contributes to chip control problems. High speeds generate excessive chips that overwhelm removal systems. Low speeds produce larger chips that are difficult to manage. Operators should adjust cutting speeds to optimize chip production.

Solutions for Effective Chip Control in CNC Machines

Improving Chip Removal Systems

Improving chip removal systems enhances CNC machine performance. Install advanced systems with higher capacity for better efficiency. Regularly clean and maintain existing systems to prevent blockages. Effective removal systems reduce downtime and improve product quality.

Adjusting Cutting Speed and Feed Rate

Adjusting cutting speed and feed rate optimizes chip control. Operators should experiment with different settings to find the best combination. Proper adjustments minimize chip size and improve removal efficiency. Consistent monitoring ensures optimal machine operation.

Practical Tips:

Upgrade to high-capacity chip removal systems.

Conduct regular maintenance to keep systems clear.

Test various cutting speeds to achieve ideal chip size.

Monitor machine performance to ensure effective chip control.

Implementing these solutions improves chip management in CNC machines. Efficient chip control enhances machine reliability and product quality. These practices contribute to smooth and uninterrupted manufacturing processes.

Addressing CNC machine problems is crucial for maintaining optimal performance. Implement the solutions provided to enhance machine reliability and efficiency. Regular maintenance plays a vital role in preventing issues like overheating and mechanical failures. Proper care extends the longevity of CNC machines, ensuring smooth operations. Operators should prioritize maintenance schedules and inspections. These practices minimize downtime and improve productivity. By focusing on these strategies, you can achieve consistent quality and precision in manufacturing processes.

See Also

Resolving Issues with Thread Milling on CNC Machining Machines

Addressing Obstacles: Improving CNC Prototyping Precision and Productivity

Comprehending Key Steps in CNC Precision Machining

Resolving the Machining Predicament: NC Milling and CNC Engraving for Best Outcomes

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com