Top 5 CNC Machining Services Every Business Needs

CNC machining has become the backbone of modern manufacturing. It empowers you to achieve unmatched precision and efficiency in production. With automation at its core, CNC machining services streamline processes, reduce costs, and enable the creation of intricate designs that traditional methods cannot replicate. This technology is essential for industries like aerospace and electronics, where accuracy and innovation are non-negotiable.

The global CNC machine market is projected to reach $128.86 billion by 2026, driven by the demand for cost-effective and advanced manufacturing solutions. By adopting CNC machining, you can minimize material waste, conserve resources, and stay ahead in a competitive market. Businesses that embrace these services position themselves as leaders in innovation and efficiency.

Key Takeaways

CNC machining improves accuracy and speed in making products. It is important for industries like airplanes and electronics.

Precision CNC machining gives exact results and repeats tasks well. It lowers mistakes and saves money by using less material.

CNC prototyping helps create products faster. It lets businesses test ideas quickly and avoid big mistakes in large production.

Custom CNC work makes special parts for unique needs. This helps create new ideas and make complicated parts.

Regular CNC fixing and care keeps machines working longer. It reduces breaks and saves money over time.

Precision CNC Machining Services

Overview of Precision CNC Machining

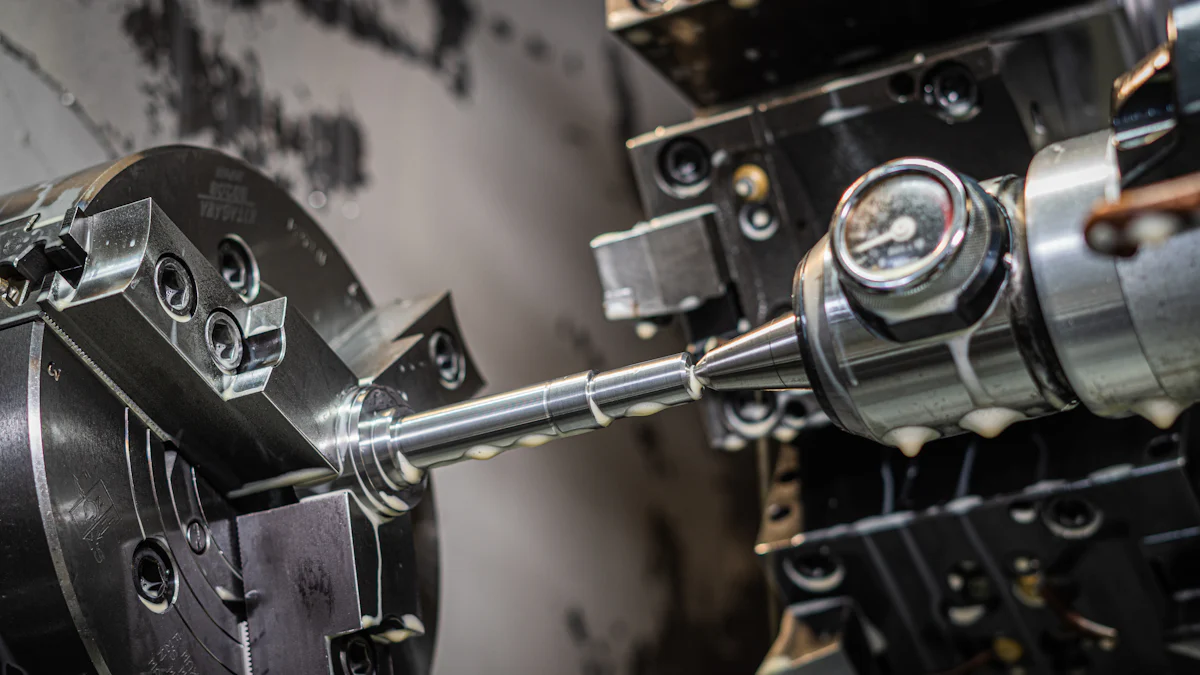

Precision CNC machining is the cornerstone of modern manufacturing. It allows you to produce parts with exceptional accuracy and consistency, ensuring every component meets exact specifications. This process uses advanced computer-controlled machines to create intricate designs that manual methods cannot replicate. Whether you need prototypes or large-scale production, precision CNC machining delivers unmatched quality and efficiency.

Feature | Description |

|---|---|

Unmatched Precision | CNC machining produces parts with incredible accuracy, minimizing human error and ensuring high quality. |

Enhanced Efficiency | CNC machines can operate continuously, increasing productivity and reducing lead times. |

Flexibility and Versatility | Easily programmed to create various parts, adapting to different materials and designs. |

Complex Geometries | Capable of producing intricate designs that are difficult to achieve with manual methods. |

Key Benefits

High accuracy and repeatability

Precision CNC machining ensures consistent results, even for the most complex designs. You can achieve tolerances as tight as +/- 0.001mm, making it ideal for industries where precision is critical. This level of accuracy eliminates errors, reduces rework, and guarantees high-quality products every time.

Reduced material waste and cost savings

By optimizing material usage, precision CNC machining minimizes waste. You save on raw materials and reduce production costs. Additionally, the efficiency of CNC machines shortens production cycles, allowing you to meet deadlines without compromising quality.

Applications in Business

Industries requiring tight tolerances

Precision CNC machining is indispensable for industries like aerospace, automotive, medical, and electronics. These sectors demand components with exact specifications to ensure safety, reliability, and performance. For example:

Aerospace: Safety-critical parts with tight tolerances.

Automotive: Rapid production of custom and standard parts.

Medical: High-quality components for devices and tools.

Electronics: Precision parts for consistent production and prototyping.

Scalability for both small and large production runs

Whether you need a single prototype or thousands of units, precision CNC machining adapts to your needs. Its scalability ensures you can handle small-batch production or ramp up for large-scale manufacturing without sacrificing quality. This flexibility makes it a valuable asset for any business aiming to grow and innovate.

CNC Prototyping Services

What Are CNC Prototyping Services?

CNC prototyping services allow you to create prototypes that closely resemble the final product in terms of appearance, functionality, and feel. Unlike traditional methods, CNC prototyping delivers superior strength and mechanical properties, including stiffness and hardness. This process achieves tight tolerances of up to one-ten-thousandth of an inch, making it ideal for intricate designs. You can also use CNC machining on a wide range of materials, such as metals, plastics, and wood, giving you unmatched versatility.

CNC prototyping stands out because it bridges the gap between concept and production. It ensures your prototypes are not only visually accurate but also structurally reliable.

Advantages of Prototyping with CNC

Accelerated product development

CNC prototyping speeds up your product development process. By quickly producing high-quality prototypes, you can test and refine your designs without delays. This rapid turnaround helps you bring your products to market faster, giving you a competitive edge.

Cost-effective design validation

Validating your designs with CNC prototypes saves money. You can identify and fix potential issues early, avoiding costly errors during mass production. The precision of CNC machining ensures your prototypes meet exact specifications, reducing the need for rework.

Why Businesses Rely on CNC Prototyping

Reduces risks of design flaws

CNC prototyping minimizes the risks of design flaws by creating accurate and detailed prototypes. This accuracy allows you to spot potential issues early in the development cycle. By addressing these flaws upfront, you avoid expensive mistakes during full-scale production. The reliability of CNC prototypes ensures your final product meets the highest standards.

Enables iterative improvements before mass production

With CNC prototyping, you can refine your designs through multiple iterations. This iterative process helps you perfect your product before committing to large-scale manufacturing. The precision and speed of CNC machining make it easy to test and improve your designs, ensuring your product is ready for success.

Industries like automotive, medical, and aerospace rely heavily on CNC prototyping to innovate and maintain quality. Whether you're developing consumer products or industrial equipment, CNC prototyping gives you the tools to succeed.

Custom CNC Fabrication Services

What Is Custom CNC Fabrication?

Custom CNC fabrication uses advanced techniques like CNC milling and turning to create parts tailored to your specific needs. Unlike standard CNC machining, this process combines multiple elements into a single part, delivering unique features and exceptional quality. It produces stronger components with finer tolerances compared to methods like molding or 3D printing. Whether you need grooves, contours, or intricate threads, custom CNC fabrication ensures precision and durability for even the most complex designs.

Custom CNC fabrication stands out because it offers unmatched flexibility and accuracy, making it the go-to solution for businesses seeking innovative and high-quality parts.

Benefits of Custom Fabrication

Tailored solutions for unique requirements

Custom CNC fabrication gives you the freedom to design parts without adhering to set standards. This flexibility allows you to create components that perfectly match your unique requirements. Whether you need intricate geometries or specialized features, this service ensures your designs come to life with precision.

Compatibility with diverse materials and finishes

Custom CNC fabrication works with a wide range of materials, including metals, plastics, and composites. You can also choose from various finishes to enhance the appearance and functionality of your parts. For example:

Polishing creates a high-gloss, mirror-like finish, improving corrosion resistance and cleanliness. It’s ideal for materials like aluminum, stainless steel, and brass.

Business Use Cases

Innovation through custom designs

Custom CNC fabrication empowers you to innovate by creating designs that stand out. Whether you’re developing a groundbreaking product or improving an existing one, this service helps you push the boundaries of what’s possible. Its precision and versatility make it an essential tool for driving innovation in your business.

Production of complex or intricate parts

Industries like medical, automotive, and defense rely on custom CNC fabrication for producing intricate parts. Here are some examples:

Industry | Applications |

|---|---|

Medical | Instruments, prosthetics, research equipment, sterile packaging, and implants. |

Automotive | Wheel disks, spoilers, roof panels, and gearboxes. |

Defense | Electronics, communication components, plane parts, and transportation components. |

Custom CNC fabrication ensures these parts meet the highest standards of quality and performance, making it a valuable asset for any business.

CNC Repair and Maintenance Services

Importance of CNC Repair and Maintenance

CNC machines are the backbone of your production process. Without proper repair and maintenance, these machines can become liabilities instead of assets. Regular upkeep ensures your equipment operates at peak performance, reducing the risk of unexpected breakdowns. Neglecting maintenance can lead to unplanned downtime, escalating repair costs, and compromised product quality. These issues not only disrupt your operations but also harm your reputation and bottom line. By prioritizing CNC repair and maintenance, you safeguard your investment and maintain a competitive edge.

A well-maintained CNC machine is more than just a tool—it's a key driver of your business success.

Benefits of Regular Maintenance

Prolongs machine lifespan

Routine maintenance extends the life of your CNC machines. Regular cleaning and lubrication prevent wear and tear on critical components. Inspections and calibrations help you identify potential issues early, avoiding costly repairs. Implementing a preventive maintenance schedule minimizes unexpected failures, ensuring your machines remain reliable for years to come.

Minimizes downtime and operational disruptions

Downtime can cripple your production schedule and lead to significant revenue loss. Regular maintenance keeps your machines running smoothly, reducing the likelihood of sudden breakdowns. Trained operators who understand routine maintenance tasks can further prevent disruptions. By following safety protocols and addressing minor issues promptly, you keep your operations on track and avoid costly delays.

Why Businesses Need These Services

Ensures consistent performance and reliability

CNC repair and maintenance services ensure your machines deliver consistent, high-quality results. Wear and tear can compromise accuracy, leading to defective products and dissatisfied customers. Regular upkeep preserves the precision of your equipment, allowing you to meet customer expectations and maintain trust in your brand.

Reduces long-term operational costs

Neglecting maintenance can have costly consequences. Minor issues often escalate into major malfunctions, requiring expensive repairs or even machine replacements. Poorly maintained machines also pose safety risks, increasing the likelihood of accidents and legal liabilities. By investing in regular maintenance, you reduce these risks and save money in the long run. A proactive approach to CNC repair and maintenance protects your bottom line and ensures your business remains competitive.

Don't let small issues snowball into major problems. Regular maintenance is the key to keeping your cnc machining operations efficient and cost-effective.

CNC Quality Inspection Services

What Is CNC Quality Inspection?

CNC quality inspection ensures that every part you produce meets strict standards of accuracy and integrity. This process involves detailed checks, such as dimensional measurements and material analysis, to verify compliance with design specifications. By identifying deviations early, you can prevent defects and maintain high manufacturing standards. Tools like Coordinate Measuring Machines (CMM), calipers, and micrometers play a vital role in achieving precise measurements. Non-destructive testing methods, such as ultrasonic and X-ray inspections, help detect flaws without damaging the parts. These inspections are critical for delivering reliable products and ensuring customer satisfaction.

CNC quality inspection is not just a step in the process—it’s your guarantee of excellence.

Benefits of Quality Inspection

Ensures compliance with specifications

CNC quality inspection ensures your products meet industry standards and customer requirements. Certifications like ISO 9001 and AS9100 demonstrate your commitment to quality. For example:

Certification | Description |

|---|---|

ISO 9001 | A globally recognized standard for quality management systems, ensuring customer and regulatory requirements are met. |

AS9100 | A specialized standard for the aerospace industry, incorporating safety and quality criteria. |

By adhering to these standards, you build trust and credibility in your market.

Enhances product reliability and customer trust

Reliable products foster customer loyalty. CNC quality inspection eliminates defects, ensuring your parts perform as intended. Tools like surface roughness testers and hardness testers verify that materials and finishes meet expectations. When your products consistently deliver on quality, you strengthen your reputation and gain a competitive edge.

Relevance to Businesses

Essential for industries with strict quality standards

Industries like aerospace, medical, automotive, and defense rely heavily on CNC quality inspection. These sectors demand precision and safety, making quality control non-negotiable. For example, aerospace components must meet rigorous standards to ensure flight safety, while medical devices require flawless accuracy to protect patient health. By implementing CNC quality inspection, you meet these high expectations and avoid costly recalls or failures.

Prevents defective products from reaching the market

Defective products can damage your brand and lead to financial losses. CNC quality inspection acts as a safeguard, catching errors before they leave your facility. Dimensional checks, material analysis, and surface inspections ensure every part meets your specifications. This proactive approach reduces waste, saves costs, and protects your reputation.

Investing in CNC quality inspection is not just about meeting standards—it’s about exceeding expectations and driving long-term success.

The top 5 CNC machining services—precision machining, prototyping, custom fabrication, repair and maintenance, and quality inspection—are essential for driving your business forward. These services enhance efficiency, ensure precision, and foster innovation. Providers like Rapid Direct, Proto Labs, and emachine Shop offer advanced capabilities, quick turnarounds, and tools like instant cost analysis to streamline your projects.

Before choosing a service, evaluate the provider’s expertise, certifications, and equipment. Ensure they align with your project’s needs and timelines.

Assess their capabilities and technology.

Verify their quality standards and certifications.

By leveraging these services, you position your business for growth and success.

FAQ

What industries benefit the most from CNC machining services?

Industries like aerospace, automotive, medical, and electronics rely heavily on CNC machining services. These sectors demand precision, efficiency, and innovation. By partnering with cnc machining companies, you can meet strict quality standards and produce high-performance components that set your business apart.

How do online CNC machining services work?

Online cnc machining services simplify the cnc manufacturing process. You upload your design files, select materials, and receive instant quotes. These platforms connect you with cnc machining companies that deliver fast, reliable, and cost-effective cnc machining solutions tailored to your needs.

Why should I choose CNC machining over traditional methods?

CNC machining offers unmatched accuracy, repeatability, and speed. It reduces material waste and ensures consistent quality. With advanced cnc machining capabilities, you can create intricate designs and scale production efficiently. This makes CNC machining a superior choice for modern manufacturing.

Can CNC machining handle custom designs?

Yes, CNC machining excels at producing custom parts. Its flexibility allows you to create unique designs with tight tolerances. Whether you need prototypes or large-scale production, cnc machining companies provide tailored solutions to meet your specific requirements.

How do I find the right CNC machining company?

Look for cnc machining companies with proven expertise, certifications, and advanced cnc machining capabilities. Check their reviews, turnaround times, and material options. Online cnc machining platforms make it easy to compare providers and choose the best fit for your project.

See Also

Top 5 CNC Technology Applications You Should Understand

Understanding CNC Machining Services for Accurate Production

Streamlined CNC Machining Services for Precision Production

Key CNC Drilling Skills for Creating Precision Components

Comprehensive CNC Milling Services Guide: All You Should Know

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com