The Top Customization Options Available with CNC Machining

CNC machining gives you the power to create parts tailored to your exact needs. Its popularity is skyrocketing, with the global market expected to hit $128.86 billion by 2026. Industries like oil and gas, robotics, and consumer goods rely on it for precision and efficiency. Automation makes it even more accessible.

Key Takeaways

CNC machining lets you pick from many materials like metals and plastics. This helps you find the right one for your project.

CNC machines make parts with exact sizes, so they fit well. This is very important for fields like aerospace and medical where accuracy matters.

Surface finishes improve how parts look and work. They are important for things like gadgets and airplane parts.

Material Selection in CNC Machining

Versatility of Material Choices

When it comes to CNC machining, you’ve got a wide range of materials to choose from. Whether you need metals, plastics, or composites, there’s something for every project. Metals like aluminum, stainless steel, and titanium are popular for their strength and durability. Plastics such as ABS and nylon are lightweight and versatile, making them ideal for prototypes or consumer products. Even advanced materials like carbon fiber composites can be used for high-performance applications. This versatility ensures you can find the perfect material to match your specific needs.

Impact of Material Properties on Performance

The material you select directly affects how your CNC-machined part performs. For example:

Strength: Essential for parts that handle heavy loads or high stress.

Toughness: Important for components exposed to impact or vibration.

Wear Resistance: Critical for parts that face constant friction, like gears or bearings.

Each property plays a role in determining the durability and functionality of your part. For instance, aluminum’s lightweight nature makes it perfect for aerospace applications, while stainless steel’s corrosion resistance is ideal for marine environments. By understanding these properties, you can ensure your parts meet both functional and environmental demands.

Common Materials and Their Applications

Here’s a quick look at some commonly used materials and where they shine:

Material | Applications |

|---|---|

Aluminum | Automotive engine parts, aerospace frames, consumer electronics, construction, medical industry |

Stainless Steel | Outdoor enclosures, medical equipment, marine applications, fasteners (bolts, screws) |

Carbon Steel | Mechanical fasteners, structural components (beams) |

Copper | Electrical wire, magnetic devices, jewelry production |

Titanium | Biomedical industry, military, aerospace, high-performance machined parts |

Magnesium | High-temperature parts, lightweight vehicles |

Each material has unique strengths. For example, copper’s excellent conductivity makes it perfect for electrical applications, while titanium’s high strength-to-weight ratio is a favorite in the aerospace and medical industries. With so many options, you can tailor your material choice to fit your project’s exact requirements.

Precision Tolerances in CNC Machining

Importance of Tight Tolerances

When it comes to CNC machining, tight tolerances are a game-changer. They ensure that every part you produce fits perfectly and functions as intended. Imagine assembling a machine where even a tiny misalignment could cause failure. That’s where precision tolerances come in. Most CNC machining processes achieve tolerances of about ±0.1 mm, but advanced setups can go even tighter. These tolerances are defined by international standards like those from ASME and ISO, ensuring consistency across industries.

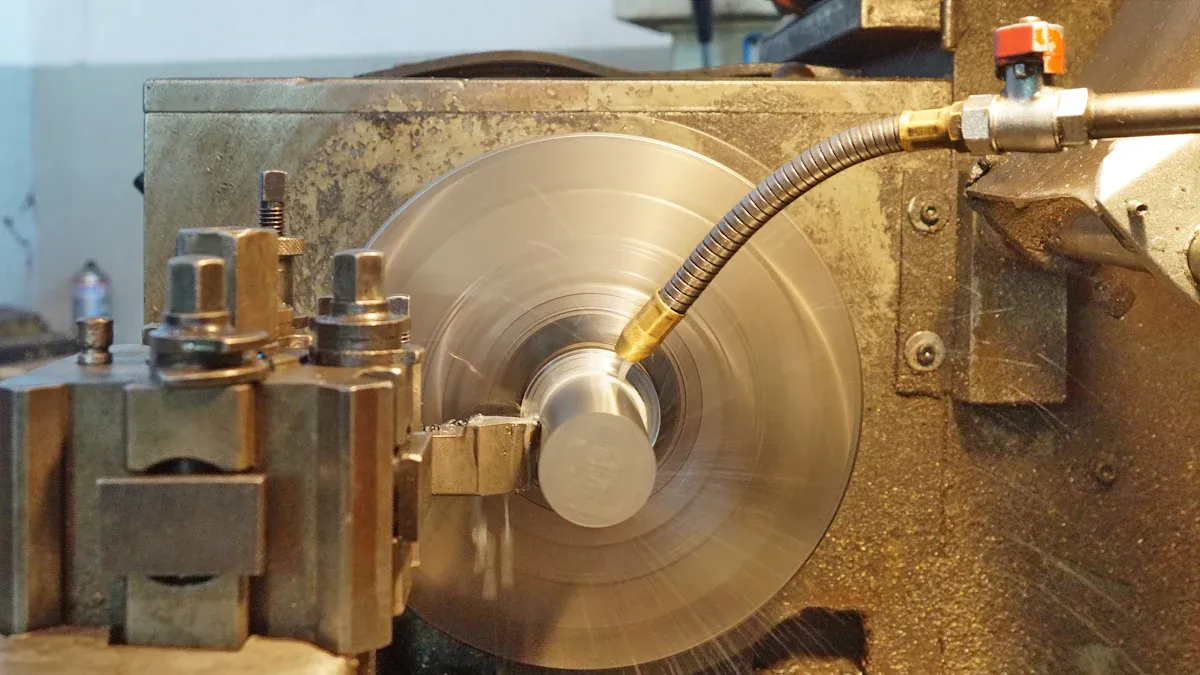

Here’s a quick comparison of tolerance levels across different processes:

Processes | Tolerance Standards |

|---|---|

Milling (3-axis or 5-axis) | ± 0.13 mm or 0.005” |

Lathe | ± 0.13 mm or 0.005” |

Engraving | ± 0.13 mm or 0.005” |

Router | ± 0.13 mm or 0.005” |

Steel Rule Die Cutting | ± 0.381 mm or 0.015” |

These tight tolerances make CNC machining a top choice for industries that demand precision.

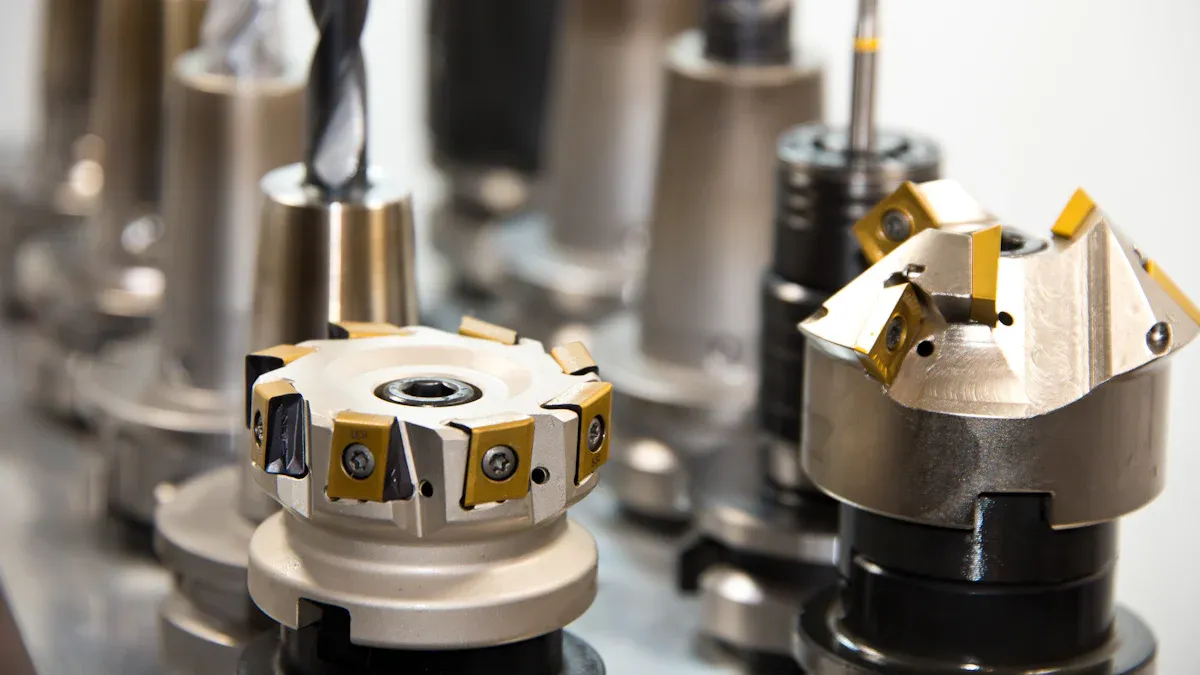

Techniques for Achieving High Precision

Achieving high precision isn’t just about the machine—it’s about the entire process. You can use advanced cutting tools made from materials like carbide or diamond coatings for better accuracy. Cryogenic machining, which uses liquid nitrogen as a coolant, reduces heat and extends tool life. Automation technologies, like robotic arms, ensure consistent results across production runs.

Here’s how precision is enhanced step by step:

Operators inspect cutting edges and tool lengths during setup.

Cutting parameters like speed and feed rate are fine-tuned.

Multi-axis machining minimizes setup changes, boosting accuracy.

These techniques allow you to create parts with intricate designs and tight tolerances, even for the most demanding applications.

Industries Benefiting from Precision

Precision tolerances are essential in industries where even the smallest error can have big consequences. For example:

The aerospace industry relies on precision machining for mission-critical components. Tight tolerances ensure these parts perform flawlessly under extreme conditions.

The medical field also demands high precision for devices like implants and surgical tools. Automotive manufacturers need exact tolerances to ensure parts fit seamlessly into complex assemblies. Other sectors, like defense, electronics, and oil and gas, also benefit from CNC machining’s unmatched accuracy.

Whether you’re building a jet engine or a medical implant, precision tolerances ensure your parts meet the highest standards of quality and performance.

Surface Finishes for CNC-Machined Parts

Types of Surface Finishes Available

Surface finishes in CNC machining go beyond just looks—they also improve functionality. You can choose from a variety of methods depending on your needs. Polishing creates a high-gloss finish using abrasives or chemical agents, making it ideal for parts requiring a sleek appearance. Bead blasting smooths surfaces by bombarding them with tiny glass beads, giving parts a uniform texture. Anodizing, on the other hand, forms a protective oxide layer that boosts corrosion resistance and allows for color customization.

Surface finishes fall into three main categories: mechanical, chemical, and thermal. Each serves a unique purpose. Some popular options include:

Bead blasting

Anodizing (Type II & Type III)

Powder coating

Brushing

Electropolishing

These methods let you tailor the finish to match your project’s requirements, whether it’s durability, aesthetics, or both.

Enhancing Functionality and Aesthetics

A good surface finish does more than make a part look great. It can enhance performance too. For example, anodizing improves corrosion resistance, while electropolishing reduces friction and boosts sealing capabilities. A smooth finish can also optimize conductivity or reduce wear and tear.

The right finish ensures your parts perform well and look professional. Whether you’re designing a medical implant or a high-end consumer product, surface finishes play a key role in achieving the desired balance between form and function.

Real-World Applications of Surface Finishes

Surface finishes are everywhere. Golf clubs use them to control backspin and meet strict regulations. Surgical implants, like hip replacements, rely on polished surfaces for low friction and rough textures for bone integration. Even slip-resistant flooring uses specialized finishes to enhance safety.

From household items to aerospace components, surface finishes ensure products meet both functional and aesthetic demands. They’re a small detail that makes a big difference.

Complex Geometries and Intricate Designs

Capabilities of 5-Axis CNC Machining

When it comes to creating intricate designs, 5-axis CNC machining is a game-changer. Unlike 3-axis machines, which have limitations, 5-axis machining lets you produce complex geometries with incredible precision. This technology allows for simultaneous machining operations, meaning you can complete even the most complicated parts in a single setup. That saves time and reduces the chance of errors.

Here’s what makes 5-axis machining so powerful:

Complex Geometries: You can create shapes and contours that were once impossible with traditional methods.

Single-Setup Efficiency: Machining multiple sides of a part in one go improves accuracy and reduces setup time.

Superior Surface Finish: The tool maintains optimal contact with the part, resulting in smoother surfaces.

Enhanced Accuracy: Tight tolerances are consistently achieved, ensuring every detail is spot-on.

This versatility makes 5-axis CNC machining ideal for industries that demand precision and creativity.

Creating Custom and Intricate Parts

CNC machining opens up endless possibilities for custom designs. You can create functional parts like performance-enhancing car components or artistic pieces like intricate furniture and musical instruments. It’s also perfect for crafting custom accessories, such as jewelry or specialized phone cases. Need a non-standard gear or fastener? CNC machining has you covered.

This flexibility means you can bring your most creative ideas to life, whether they’re functional, decorative, or both.

Applications in Prototyping and Production

CNC machining shines in both prototyping and production. It automates processes, reducing human error and ensuring precision. You can create complex designs that traditional methods struggle to achieve. Plus, the technology supports a wide range of materials, making it versatile for different applications.

Rapid prototyping is another standout feature. CNC machining allows you to quickly produce prototypes with tolerances as tight as ±0.001 inches. This speed accelerates product development cycles, letting you test intricate designs faster. Whether you’re developing custom dies, molds, or final products, CNC machining ensures consistency and efficiency every step of the way.

Scalability and Production Flexibility

Customization for Prototyping Needs

CNC machining offers unmatched flexibility when it comes to prototyping. You can create complex shapes and intricate features without worrying about manufacturing constraints. This process allows you to experiment with innovative designs and refine them as needed. Plus, making changes to digital designs is quick and easy, so you can customize prototypes without extensive retooling.

Here’s why CNC machining is perfect for prototyping:

It supports the creation of intricate and detailed designs.

You can test and tweak concepts without production limitations.

Modifications are seamless, saving time and effort.

This level of customization ensures your prototypes align perfectly with your vision, giving you the freedom to innovate.

Transitioning to Mass Production

Once your prototype is validated, transitioning to mass production becomes straightforward with CNC machining. You can start with small batch production to test market demand and refine your product further. The same CNC setup used for prototyping can handle these smaller runs, ensuring precision and consistency.

Benefit | Explanation |

|---|---|

Cost-effectiveness | Ideal for low to medium production volumes, saving money on tooling costs. |

Design flexibility | Handles complex shapes that traditional methods struggle with. |

Scalability | Easily shifts from small batches to larger production runs. |

This seamless transition reduces lead times and simplifies the manufacturing process, making it easier to scale up when demand increases.

Cost-Effectiveness of Scalable Solutions

Scalable CNC machining solutions can save you money in several ways. You don’t need to invest in expensive machinery upfront. Instead, you can rely on service providers with the latest technology and skilled operators. This reduces labor costs and operating expenses. Precision machining also minimizes material waste, further cutting costs.

Here’s how it benefits your bottom line:

No need for large capital investments in equipment.

Lower energy and maintenance costs.

Reduced material waste due to high precision.

Flexibility to scale production based on demand, avoiding unnecessary expenses.

By leveraging these advantages, you can allocate resources more effectively and focus on growing your business.

Advanced Design Integration in CNC Machining

Role of CAD and CAM Software

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are the backbone of advanced CNC machining. These tools work together to bring your ideas to life. CAD software lets you create detailed 2D or 3D models, making it easy to design intricate geometries and specifications. Once your design is ready, CAM software steps in to translate it into precise machine instructions. This ensures every cut, drill, or movement is optimized for accuracy and efficiency.

Here’s how the process flows:

You start by designing the part in CAD software.

Simulate and test the design to catch any flaws.

Import the design into CAM software to define machining operations.

Generate G-code, which tells the CNC machine exactly what to do.

Finally, the CNC machine produces the part with unmatched precision.

This seamless integration between CAD and CAM ensures a smooth transition from design to production, saving you time and effort.

Enhancing Customization Through Digital Tools

Digital tools take CNC machining to the next level. They improve precision, reduce errors, and make customization easier than ever. For example, simulation software lets you test designs virtually, identifying inefficiencies before production begins. Adaptive strategies and optimized toolpaths minimize machine operation time, while automation ensures consistent results. These tools allow you to create high-quality parts with tighter tolerances and less waste.

By leveraging these technologies, you can produce parts that meet exact specifications without compromising on efficiency.

Examples of Advanced Design Applications

CNC machining enables some truly impressive applications. Industries like aerospace and medical devices rely on it for intricate parts with high precision. You’ll also find it used for:

Custom golf clubs in sporting goods

Satellite components in space technology

Prototype production in research and development

Reactor parts in chemical processing

Recent innovations, like multi-axis machining centers, have expanded what’s possible. Whether it’s connectors for telecommunications or artistic furniture designs, CNC machining empowers you to create complex, customized parts that stand out.

CNC machining gives you the tools to innovate and meet your project’s exact needs. Its customization options make it a go-to solution for industries like aerospace, medical, and electronics. Here’s how you can leverage it:

Produce intricate parts with tight tolerances to meet evolving demands.

Use high-performance tools to machine tough materials efficiently.

Apply micromachining for miniature components in electronics and medical devices.

Whether you’re crafting lightweight aerospace parts or precise surgical instruments, CNC machining empowers you to create with precision, efficiency, and creativity.

FAQ

What industries benefit the most from CNC machining?

CNC machining is a favorite in aerospace, medical, automotive, and electronics industries. It’s perfect for creating precise, durable, and custom parts that meet strict performance standards.

Can CNC machining handle small production runs?

Absolutely! CNC machining is ideal for small batches. You can test prototypes or produce limited quantities without the high costs of traditional manufacturing methods.

How do I choose the right material for my project?

Consider your project’s requirements. Think about strength, weight, and environmental factors. For example, aluminum works for lightweight designs, while stainless steel resists corrosion in harsh conditions.

💡 Tip: Consult with your CNC machining provider to match materials with your specific needs.

See Also

Discovering CNC Machining Solutions for Accurate Production

Understanding CNC Machining: Precision, Prototypes, and Material Choices

Perfecting CNC Machining Techniques for Accurate Component Production

Streamlined CNC Machining Solutions for High-Precision Production

The Impact of CNC Machining on Advanced Precision Manufacturing

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com