Understanding the Different Types of CNC Machines for Precision Parts

CNC machines, or Computer Numerical Control machines, automate precision machining by following programmed instructions. They deliver unmatched accuracy for creating cnc precision parts. Understanding the types of CNC machines helps you select the right one for your needs. This ensures efficiency, versatility, and the ability to handle complex geometries across various materials.

Key Takeaways

CNC machines use computers to make parts with great accuracy.

Knowing about CNC types, like mills, lathes, and lasers, helps you pick the best one for your job.

Learn about new trends like robots and AI to make CNC work better and faster.

Overview of CNC Machines

What Are CNC Machines?

CNC machines, or Computer Numerical Control machines, are advanced tools that automate machining processes. They follow pre-programmed instructions to cut, shape, and finish materials with high precision. Unlike traditional tools, CNC machine tools operate with minimal human intervention, ensuring consistent results. These machines are versatile and can handle various materials, including metals, plastics, and composites.

Why Are CNC Machines Essential for Precision Machining?

You rely on CNC machines for precision machining because they deliver unmatched accuracy and efficiency. Industries like aerospace, medical, and electronics depend on these machines to produce intricate parts. For example, CNC machining creates components for surgical tools, circuit boards, and even wind turbines. The ability to handle complex geometries and tight tolerances makes CNC machines indispensable for manufacturing cnc precision parts.

Key Features of CNC Machine Tools

CNC machine tools offer several advanced features that set them apart from traditional tools:

Multi-axis coordinated control: Enables simultaneous movement of multiple axes for complex machining tasks.

Tool position compensation: Adjusts for tool wear to maintain precision.

Machining simulation: Tests processes virtually to prevent errors.

Online programming: Lets you make real-time adjustments directly on the machine.

Tool management and monitoring: Tracks tool usage to reduce downtime.

Online inspection: Ensures machining quality during production.

These features make CNC machine tools efficient and reliable for various types of cnc machine tools. Whether you need to produce small batches or large volumes, these machines optimize the process while maintaining accuracy.

Types of CNC Machines and Their Applications

CNC Milling Machines

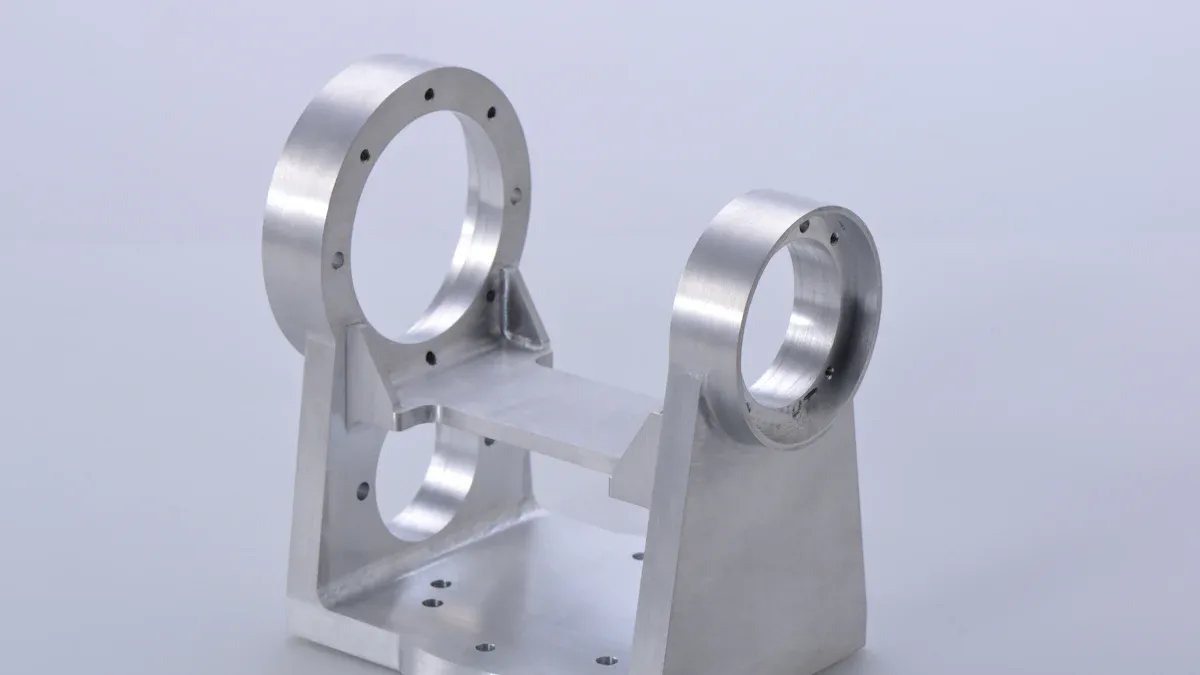

CNC milling machines are among the most versatile types of CNC machine tools. These machines use G-code to control precise movements, allowing you to create complex geometries and detailed parts. They can handle various materials, including metals, plastics, and composites. Industries like aerospace, automotive, and medical rely on CNC milling machines to produce high-tolerance components. For example, they are essential for crafting engine parts, surgical instruments, and electronic housings. Their adaptability makes them a cornerstone of cnc machining.

CNC Lathes

CNC lathes and turning centers specialize in shaping cylindrical workpieces. These machines use cnc turning tools to remove material around the axis of rotation. You can perform various operations, such as counter-bore drilling, surface finishing, and creating circular grooves. CNC lathe machines are ideal for producing cnc machined parts like shafts, bushings, and threaded components. Their precision ensures dimensional accuracy and stability, which is crucial for industries like automotive and aerospace.

CNC Plasma Cutters

CNC plasma cutters excel at cutting conductive metals like steel and aluminum. These machines can handle material thicknesses up to 1.5 inches, making them suitable for heavy-duty applications. Plasma cutting is less precise than laser cutting but works well for thicker materials. You’ll find these cutters in industries like construction and shipbuilding, where speed and efficiency are critical.

CNC Laser Cutters

CNC laser cutters offer unmatched precision, with tolerances as tight as 0.002 inches. These machines can cut a variety of materials, including non-conductive ones like wood and plastic. They are perfect for applications requiring intricate designs, such as jewelry making and electronics manufacturing. Laser cutting provides a clean finish, reducing the need for additional processing.

CNC Electric Discharge Machines (EDM)

CNC electric discharge machines use thermal energy to shape hard-to-machine materials. These machines excel at creating intricate designs without applying cutting forces. You can use EDM for tasks like processing hardened materials or crafting delicate components. The process is highly automated, reducing manual intervention and ensuring consistent results.

CNC Routers and Drilling Machines

CNC routers are ideal for cutting and shaping softer materials like wood, plastic, and foam. These machines are widely used in woodworking and furniture manufacturing. CNC drilling tools, on the other hand, focus on creating precise holes in materials. They are essential for applications like circuit board production and automotive part assembly.

CNC Grinding Machines

CNC grinding machines deliver exceptional precision, often achieving tolerances as tight as 0.001 inches. These machines are versatile, handling various shapes and materials. You can use them for surface grinding, cylindrical grinding, and more. Industries like aerospace and medical rely on CNC grinding for components requiring smooth finishes and exact dimensions. The automation of these machines ensures consistent quality and reduces human error.

Categorization by Axes and Motion Control

2-Axis, 3-Axis, and 5-Axis CNC Machines

The number of axes in a CNC machine determines its capabilities and complexity. A 2-axis machine operates on two linear axes, typically X and Y, making it suitable for simpler tasks like cutting flat shapes. A 3-axis machine adds the Z-axis, enabling vertical movement for more intricate designs. For advanced machining, 5-axis CNC machines include two additional rotational axes (A and B), allowing the cutting tool to approach the workpiece from virtually any angle.

Factor | 3-Axis | 5-Axis |

|---|---|---|

Cutting tool movement | Moves along X, Y, and Z | Moves along X, Y, Z, A, and B axes |

Efficiency | Good | Excellent, quick |

Tool changes | Requires multiple setups | Minimal, works on all sides |

Capabilities | Limited | Handles intricate shapes |

Accuracy | Good | Excellent |

Ease of operation | Minimal training needed | Requires specialized expertise |

Cost | $25,000 to $50,000 | $80,000 to over $500,000 |

Applications | Simpler parts | Complex parts like medical implants |

Linear vs. Rotational Motion Control

CNC machines use two types of motion control: linear and rotational. Linear motion involves straight-line movements along the X, Y, and Z axes. Rotational motion adds flexibility by allowing the cutting tool or workpiece to rotate around additional axes, such as A and B. This combination enhances the machine's ability to create complex geometries and smooth contours.

How Axes Impact Precision and Complexity

The number of axes directly affects the precision and complexity of machining. A 3-axis machine struggles with intricate geometries, as it cannot reach certain areas without repositioning the workpiece. In contrast, a 5-axis machine eliminates this limitation by rotating the workpiece or tool, ensuring optimal positioning. This capability reduces manufacturing time and improves accuracy, making it ideal for industries like aerospace that demand high precision. Multi-axis cnc machines also enable synchronized motion, enhancing repeatability and overall quality.

Key Factors to Consider When Choosing a CNC Machine

Material Compatibility

Selecting the right CNC machine starts with understanding material compatibility. You must evaluate the material's properties and the part's final application. For example:

Part Application: Determine if the part will face extreme temperatures or chemical exposure.

Mechanical Factors: Assess the material's strength and wear resistance for durability.

Electrical Factors: Decide if the part needs to conduct or insulate electricity.

Cosmetic Considerations: Consider aesthetics for consumer-facing products.

Matching the material to the machine ensures optimal performance and reduces wear on CNC machine tools. This step is crucial for achieving precision machining results.

Precision and Tolerance Requirements

Precision and tolerance levels vary across CNC machining methods. You should choose a machine that meets your project's specific requirements. For instance:

CNC Machining Method | Tolerance Range |

|---|---|

CNC Laser: UV Laser Machining | ±0.0127mm to ±0.0254mm |

CNC Femto Laser Machining | ±0.001mm to ±0.010mm |

High precision ensures uniformity, sustained functionality, and compliance with industry certifications. These factors enhance product quality and support business growth.

Production Volume and Speed

Production volume and speed directly influence your choice of CNC machine. Low-volume CNC machining, ideal for 10-1000 pieces, offers flexibility and cost-effectiveness. It allows you to produce cnc precision parts quickly without the high costs of mass production. Strategic design choices and material optimization further improve efficiency. For high-volume needs, consider machines with faster cycle times and automated features.

Budget and Maintenance Costs

Budget constraints often dictate the types of CNC machines you can afford. While advanced machines like 5-axis models offer versatility, they come with higher upfront and maintenance costs. You should balance your needs with your budget. Regular maintenance also ensures the longevity of cnc machine tools, reducing downtime and repair expenses. Investing in the right machine saves money in the long run.

Latest Trends and Innovations in CNC Technology

Automation and Smart CNC Machines

Automation has revolutionized the types of CNC machines available today. Enhanced CAD/CAM systems streamline workflows, allowing you to move seamlessly from design to production. High-performance cutting tools, made from advanced materials, improve durability and cutting speeds. Techniques like cryogenic machining reduce heat, extending tool life and enabling work with hard materials. Micromachining now allows you to produce miniature components with tight tolerances, meeting the demands of industries like electronics and medical devices.

Industrial software advancements also play a key role. These tools improve precision by enabling better design modeling and simulation. You can identify design flaws early, reducing the need for rework and saving time. Automation further enhances efficiency by minimizing manual intervention, ensuring consistent results in cnc machining.

Integration with IoT and AI

The integration of IoT and AI has transformed CNC machining into a smarter, more efficient process. IoT connectivity enables real-time monitoring, allowing you to track machine performance and detect issues before they cause downtime. Predictive maintenance, powered by IoT, ensures your machines stay operational, reducing costly interruptions.

AI takes this a step further by automating repetitive tasks prone to human error. It analyzes large datasets to optimize operations, improving production capacity and consistency. By 2035, AI is projected to boost productivity by 40%, showcasing its potential in precision machining. This combination of IoT and AI supports agile production methods, helping you adapt quickly to market demands.

Advancements in Multi-Axis CNC Machines

Multi-axis CNC machines represent a significant leap in manufacturing capabilities. These machines, particularly 5-axis and 6-axis models, allow you to produce intricate parts with fewer setups. This reduces human error and enhances both accuracy and efficiency. For example, 5-axis machines feature two rotational axes in addition to the standard X, Y, and Z axes. This enables simultaneous machining of multiple surfaces, making them ideal for high-tolerance parts like turbine blades and medical implants.

The shift from basic 3-axis machining to advanced multi-axis systems has increased flexibility and precision. You can now handle complex geometries that simpler types of machines cannot achieve. This innovation minimizes the need for multiple setups, saving time and boosting productivity in high-volume production scenarios.

Understanding the types of CNC machines helps you match their capabilities to your manufacturing needs. Evaluate factors like upfront costs, production volume, and precision requirements to make an informed choice. Stay updated on CNC technology trends to enhance precision machining and remain competitive. Innovations like IoT and AI are shaping the future of cnc precision parts production.

FAQ

What is the difference between CNC milling and CNC turning?

CNC milling removes material using rotating tools, while CNC turning shapes cylindrical parts by rotating the workpiece. Milling handles complex geometries; turning specializes in symmetrical components.

How do you choose between 3-axis and 5-axis CNC machines?

Choose 3-axis for simpler parts and lower costs. Opt for 5-axis when producing intricate designs or high-precision components, especially in aerospace or medical industries.

Can CNC machines work with all materials?

CNC machines handle most materials, including metals, plastics, and composites. However, you must match the machine type and cutting tools to the material's properties for optimal results.

See Also

Decoding the Order of Precision Parts in CNC Machining

Grasping the Key Procedures in CNC Precision Machining

Excelling in CNC Machining for Precision Component Production

Investigating CNC Machining Solutions for Accurate Manufacturing

Comprehending CNC Precision Machining Features: An Overview of CNC Turning

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com