How CNC Milling and Turning Shape Flashlight Components

CNC milling and turning make flashlight components with great accuracy. These methods shape the flashlight's body and internal parts. Milling uses tools to cut detailed designs, while turning creates smooth, round shapes. These processes ensure the components are strong and function well. Making flashlights requires precise work, and CNC machines excel at that. Whether for camping or emergencies, these methods produce top-quality flashlights.

Key Takeaways

CNC milling makes detailed flashlight parts with great accuracy. It works well for tricky designs like reflector housings.

CNC turning makes smooth, round flashlight parts quickly. It ensures precise shapes for parts like bodies and battery holders.

Picking the right CNC method depends on the part's shape. Milling is great for detailed designs, while turning is best for round shapes.

Using both CNC milling and turning improves flashlight parts. It helps make detailed designs and smooth surfaces.

Aluminum is great for flashlight parts because it is light, strong, and doesn’t rust. This makes it a top choice for making flashlights.

CNC Milling for Flashlight Components

What Is CNC Milling?

Definition and purpose of CNC milling

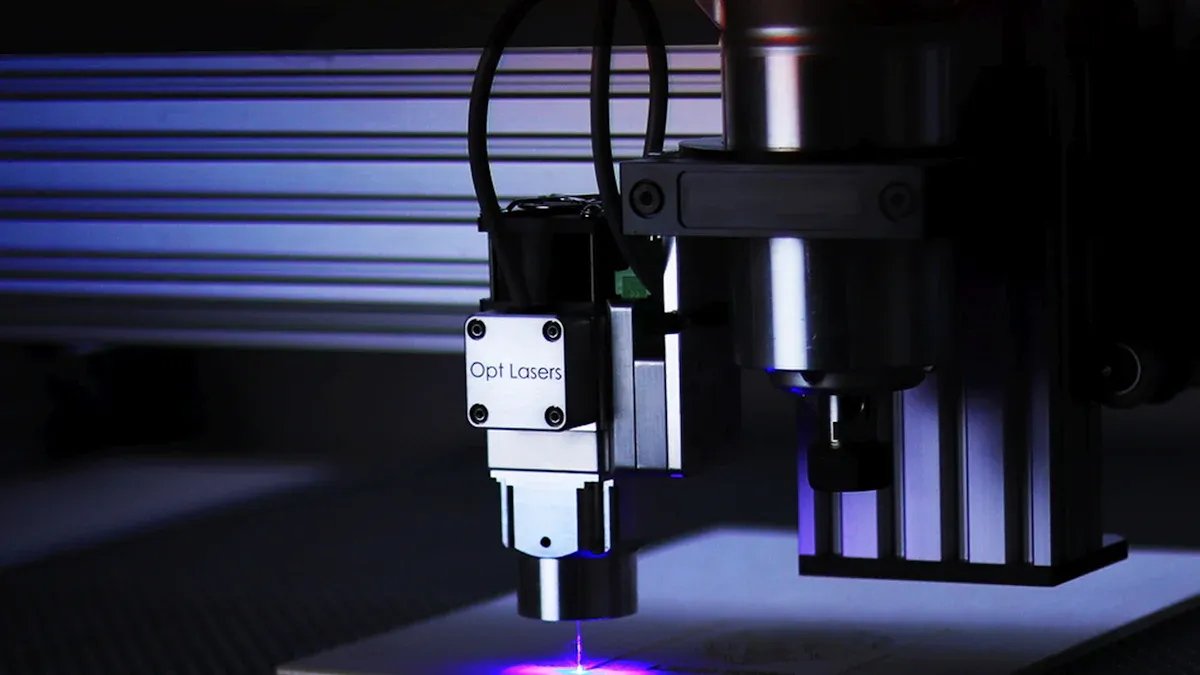

CNC milling uses computer-guided tools to shape materials. It removes material to create detailed designs and exact shapes. This process is perfect for making flashlight parts. The main goal is to make accurate and repeatable designs.

How CNC milling works: Cutting tools and workpiece movement

In CNC milling, tools spin while the material stays still or moves. First, a 3D design is made using CAD software. Then, CAM software turns it into CNC instructions. The machine follows these steps to cut and shape parts precisely. Key steps include:

Design and Programming: Create the design and turn it into CNC code.

Setup and Calibration: Secure the material and adjust tools for accuracy.

Cutting and Machining: The machine cuts and polishes automatically.

Quality Control and Inspection: Check the product to ensure it meets standards.

Advantages of CNC Milling

Precision and ability to create complex geometries

CNC milling makes detailed designs like grooves on flashlight shells. It controls speed and cutting rates for exact results. This is important for making parts with smooth finishes and tight measurements.

Material compatibility for intricate flashlight components

CNC milling works with many materials, like aluminum. Aluminum is light, strong, and resists rust, making it great for flashlight shells. CNC milling handles delicate materials carefully, ensuring strong and reliable parts.

Applications of CNC Milling in Flashlight Manufacturing

Examples of flashlight parts made with CNC milling

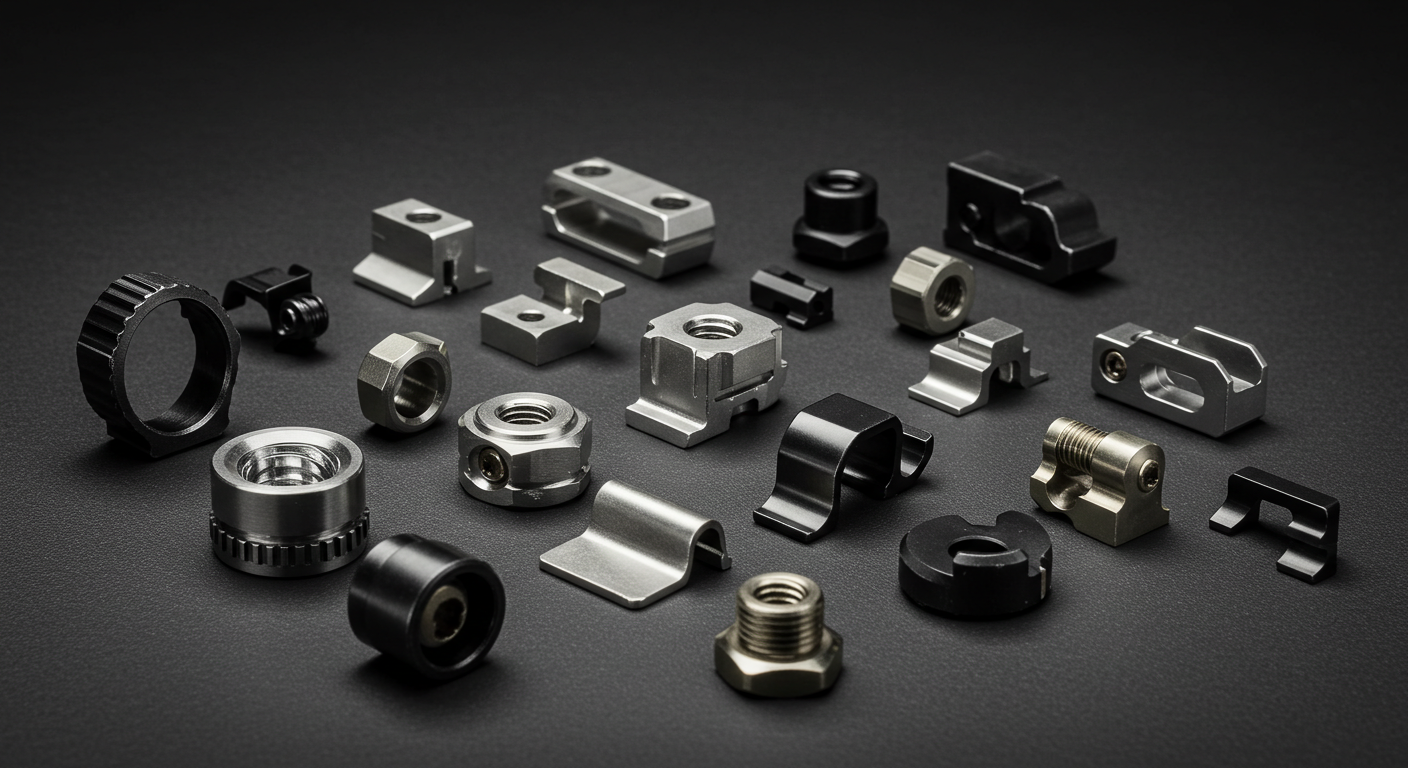

CNC milling creates many flashlight parts, such as:

Flashlight shells: Includes the body, reflector housing, and front cover.

Strong light shells: Includes aluminum heads, battery tubes, and tail caps.

Component | Description | Material Used |

|---|---|---|

Flashlight Shell | Cylinder, luminous body, back cover, main body, reflector, and front cover. | Aluminum Alloy |

Strong Light Shell | Aluminum head, battery tube, focusing ridge, and tail cap. | Aluminum |

Machining Process | CNC lathe used for precise shaping of complex parts. | N/A |

Why CNC milling is ideal for these parts

CNC milling is great for parts needing detailed designs and accuracy. It ensures smooth finishes and exact sizes for both looks and function. This process also makes durable parts quickly, so flashlights work well in tough conditions.

CNC Turning for Flashlight Components

What Is CNC Turning?

Definition and purpose of CNC turning

CNC turning is a process where a spinning material is shaped. A fixed cutting tool is used to carve the rotating piece. This method is great for making round flashlight parts. The main goal is to create smooth, precise, and strong pieces. Industries like cars and planes often use CNC turning for its accuracy.

How CNC turning works: Rotating workpiece and stationary cutting tool

In CNC turning, the material spins fast while the tool stays still. First, a design is made using CAD software. Then, it is turned into instructions for the CNC machine. The machine shapes the material in steps: rough cutting, semi-finishing, finishing, and polishing. These steps make sure the parts are smooth and accurate.

Advantages of CNC Turning

Efficiency in producing cylindrical and symmetrical parts

CNC turning is great for making round flashlight parts like bodies. It works quickly and precisely, which is good for making many parts. The process creates smoother surfaces than other methods. This makes it a smart and cost-saving choice for flashlight production.

Material compatibility for flashlight components

CNC turning works well with materials like aluminum. Aluminum is light, strong, and doesn’t rust easily. It’s perfect for flashlight bodies because it lasts in tough conditions. CNC turning can handle many materials, making it flexible and reliable.

Applications of CNC Turning in Flashlight Manufacturing

Examples of flashlight parts made with CNC turning

CNC turning is used to make several flashlight parts, such as:

Flashlight bodies: The main tube that holds the inside parts.

Battery compartments: Sections that keep batteries in place.

Tail caps: End pieces that may have switches or seals.

Metric | Description |

|---|---|

Surface Finish | CNC turning creates smoother, rounder surfaces than milling. |

Production Costs | Lower costs for making round parts with CNC turning. |

High-Volume Production | Best for making many round parts quickly and accurately. |

Why CNC turning is ideal for these parts

CNC turning is perfect for parts that need to be round and smooth. It ensures accuracy and keeps quality consistent, even for large batches. Its ability to work with aluminum and other materials makes it a top choice for flashlight manufacturing.

Comparing CNC Milling and CNC Turning for Flashlight Components

Differences in Process and Capabilities

Shape and geometry of parts produced

Milling and turning make different shapes for flashlight parts. Milling is good for detailed and flat designs. It works well for slots and complex shapes. Turning is best for round and smooth parts. It makes cylinders, tapered shapes, and threaded holes. Use milling for tricky designs. Choose turning for simple, round parts.

Precision and tolerances achievable

Both methods are very accurate but have different strengths. Milling is great for detailed parts with tight measurements. Turning is better for round parts like flashlight bodies. It ensures smooth surfaces and exact sizes. Each process is perfect for specific flashlight needs.

Material and Design Considerations

Material types best suited for each process

The material affects how well the process works. Milling handles hard materials like steel easily. Turning works better with softer metals like aluminum and brass. Aluminum is popular for flashlights. It’s light, strong, and resists rust. This makes it great for durable flashlight parts.

Process | Best Materials | Limits |

|---|---|---|

CNC Milling | Metals (aluminum, steel, brass), plastics | Handles soft and hard materials |

(acrylic, PVC, nylon), composites, some ceramics | ||

CNC Turning | Softer metals (aluminum, brass), some tough metals | Not ideal for hard metals, wood, or composites |

Design constraints and flexibility

Milling is flexible for making tricky designs. It creates detailed and non-round parts. Turning is faster but works best for simple shapes. Picking the right method helps make better flashlight parts.

Production Efficiency and Cost

Speed and scalability of each process

Turning is faster for making round parts like flashlight bodies. It’s great for making many parts quickly. Milling is slower but can make detailed shapes. It’s good for flashlights with special designs.

Cost-effectiveness for different production volumes

Aluminum is cheap and works well for flashlight parts. It’s strong and easy to shape, saving time and money. Turning is cheaper for big batches of simple parts. Milling is better for small runs of detailed designs. Choosing the right method saves money and keeps quality high.

Choosing the Right Process for Flashlight Components

Components Best Suited for CNC Milling

Examples: Reflector housings, lens frames

CNC milling works well for making detailed flashlight parts. Reflector housings and lens frames are good examples. Reflector housings need smooth surfaces and exact angles to guide light. Lens frames must have precise cuts to hold lenses tightly.

Why CNC milling is ideal for these parts

Milling is great for creating complex shapes with high accuracy. Aluminum is often used because it is light, strong, and resists rust. This process makes manufacturing easier and improves quality. Milling ensures smooth finishes and detailed designs for reflector housings and lens frames.

Components Best Suited for CNC Turning

Examples: Flashlight bodies, battery compartments

CNC turning is best for round flashlight parts like bodies and battery compartments. The flashlight body holds batteries and circuits inside. Battery compartments need exact sizes to keep batteries secure and connected.

Why CNC turning is ideal for these parts

Turning is perfect for making round parts with smooth surfaces. It is fast and precise, ideal for flashlight shells and similar parts. Aluminum is a common choice because it is light, durable, and rust-resistant. Turning ensures accuracy and is great for making many parts quickly.

When to Combine CNC Milling and Turning

Hybrid applications for flashlight components

Some flashlight parts need both milling and turning to be complete. For example, flashlight heads may need turning for the round base and milling for grooves. Using both methods helps make parts that look good and work well.

Examples of parts requiring both processes

Flashlight heads: Turning shapes the base, and milling adds grooves.

Tail caps with threads: Turning makes the round shape, and milling adds slots or patterns.

By combining these methods, you can make strong and precise parts. This ensures flashlight components meet high standards for quality and performance.

CNC milling and turning are key for making flashlight parts. Milling makes detailed, non-round pieces. Turning is best for round, even shapes. Both methods ensure parts are accurate, strong, and dependable.

Benefit | Description |

|---|---|

Better Efficiency | CNC machines cut waste and lower production costs. |

High Quality | Parts made are reliable and work very well. |

Saves Money | Automated steps boost profits and help compete in markets. |

The right method depends on the part's design and material. Talking to a CNC expert helps you choose wisely. This ensures flashlight parts are top quality.

FAQ

What is the difference between CNC milling and CNC turning?

Milling uses spinning tools to cut detailed shapes. Turning shapes materials by spinning them against a fixed tool. Milling works for tricky designs. Turning is best for round parts.

Which materials are commonly used for flashlight components?

Aluminum is popular because it’s light, strong, and doesn’t rust. Other materials include brass, steel, and plastics. The choice depends on the flashlight’s design and use.

Can CNC machines handle high-volume production?

Yes, CNC machines make many parts with the same quality. Turning is faster for round parts. Milling is better for detailed shapes. Both methods are efficient and scalable.

Why combine CNC milling and turning for flashlight parts?

Some flashlight parts need both methods to be made well. For example, flashlight heads may need turning for the base and milling for grooves. Using both ensures accuracy and good design.

How do CNC machines ensure precision?

CNC machines follow computer instructions to cut materials exactly. They use software to control speed, tool movement, and cutting depth. This keeps every part accurate and consistent.

See Also

Utilizing CNC Machining for Tactical and Outdoor Flashlight Parts

Achieving Precision Parts Production Through CNC Milling Mastery

Perfecting CNC Machining Techniques for Precision Parts Creation

CNC Turning Mastery: Crafting Precision Parts for RC Upgrades

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com