The Benefits of CNC Precision in Flashlight Design & Customization

Precision is very important in making flashlights, especially when it comes to precision parts milling. Every part needs to fit perfectly for the flashlight to work well and last long. This is where CNC precision machining helps a lot. It allows for detailed designs and super small adjustments so parts fit together perfectly.

CNC tools make the process steady by using control charts to keep everything accurate. A higher process capability index (Cpk) means better quality and more reliable flashlights. From the outer case to the inside parts, CNC precision machining and precision parts milling make flashlight production very exact. It also works great for shaping small parts, ensuring that every piece is just right.

Key Takeaways

CNC machines make flashlight parts fit well, boosting performance and strength.

With CNC, flashlights can have special designs to match user needs.

CNC lowers costs by cutting waste and needing less work, making good flashlights cheaper.

Advanced CNC tools create detailed designs and smooth looks, improving use and style.

CNC works great for small amounts, helping test and try new flashlight ideas fast.

CNC Machining in Flashlight Manufacturing

What is CNC Precision Machining?

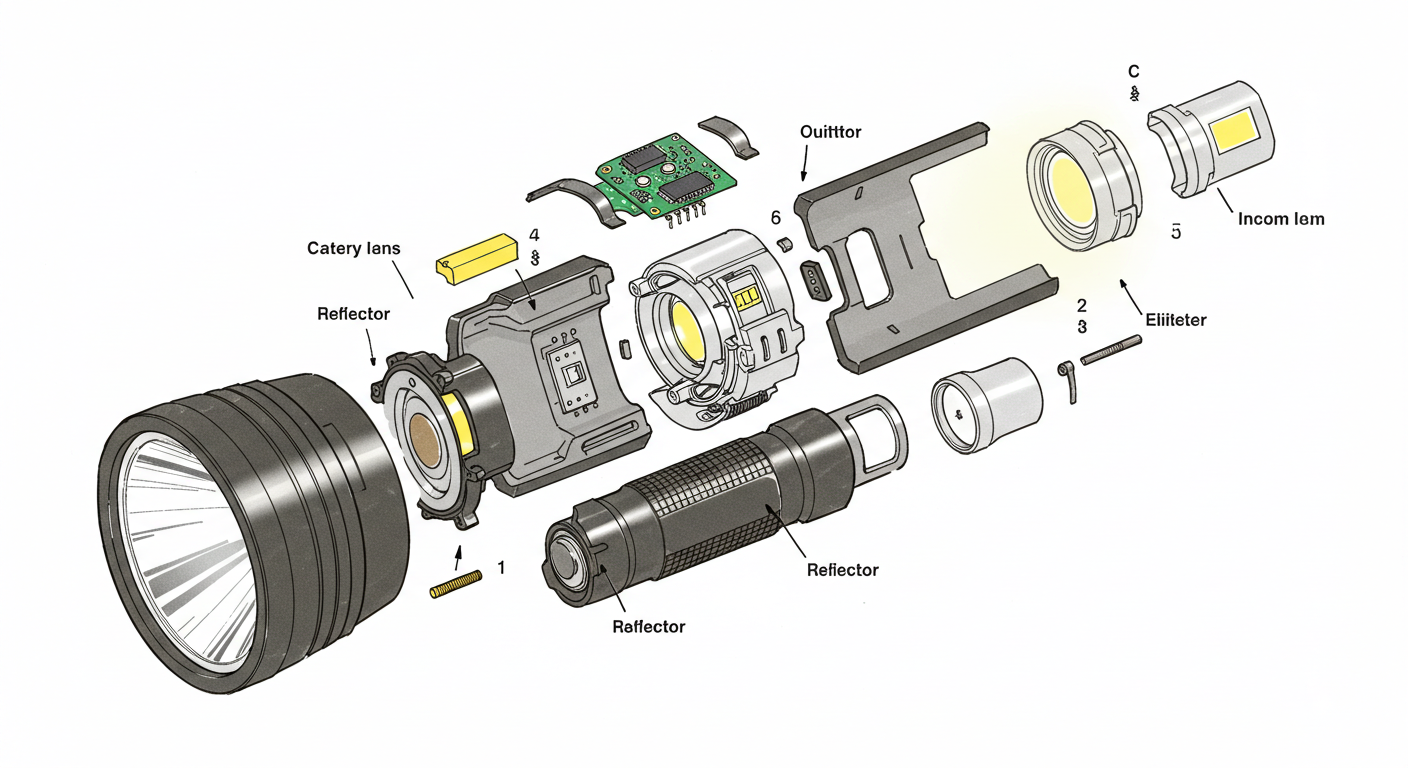

CNC precision machining uses computers to control tools for making parts. This process ensures every part is made with great accuracy. It is very important for products like flashlights. The tools cut, drill, and shape materials to meet exact sizes. These sizes, called tolerances, show how much a part can vary without causing problems.

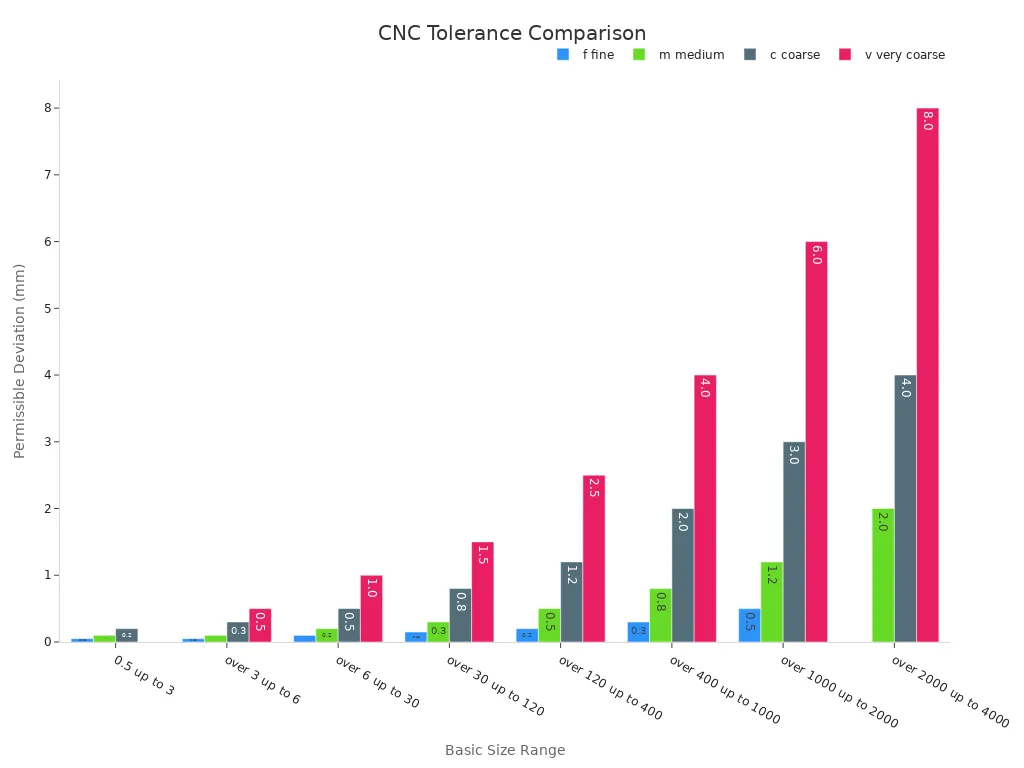

Here’s a table showing how much parts can differ in size:

Allowed size differences in mm | ||||

|---|---|---|---|---|

Size range in mm | f (fine) | m (medium) | c (coarse) | v (very coarse) |

0.5 to 3 | ±0.05 | ±0.1 | ±0.2 | – |

3 to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

6 to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

30 to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

120 to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

400 to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

1000 to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

2000 to 4000 | – | ±2.0 | ±4.0 | ±8.0 |

This precision helps flashlight parts fit perfectly. It makes them work better and last longer.

Importance of CNC Machining for Flashlight Design

CNC machining is very important for making flashlights better. It helps improve quality and allows for custom designs. People often want special finishes like polishing or anodizing. CNC machining makes sure these finishes are done evenly and correctly. It also ensures parts meet exact sizes, so flashlights work well.

Some key benefits are:

Accurate parts made with CNC precision.

Fast delivery of custom flashlight pieces.

Flexible designs for unique customer requests.

These reasons make CNC machining essential for high-quality flashlights.

How CNC Differs from Traditional Methods

CNC machining is different from older methods. It uses computers to guide tools, making parts more accurate. Older methods often cannot meet the tight sizes needed for modern flashlights. CNC machining does this easily, ensuring every part is just right.

The chart below shows how CNC machining achieves better size accuracy than older methods:

CNC machining also reduces mistakes and speeds up production. This makes it a faster and more reliable way to make flashlights.

Benefits of CNC Precision in Flashlight Design

Stronger and Longer-Lasting Flashlights

CNC machining helps make flashlights tough and long-lasting. It ensures parts fit tightly, removing weak spots in the design. This makes flashlight parts stronger and less likely to break. For example, a CNC-made flashlight case can handle drops and rough use without failing.

The process also reduces material flaws. CNC machining avoids mistakes that could cause flashlights to stop working early. This means flashlights last longer and stay reliable. With precise and repeatable methods, manufacturers can always create high-quality products.

Better Customization and Flexible Designs

CNC machining allows for creative flashlight designs. You can make unique shapes, patterns, or features with ease. These machines work with materials like aluminum, steel, and titanium. This makes it possible to design flashlights for specific uses, like camping or work.

CNC machining also creates smooth finishes. You can add polished surfaces, special coatings, or engraved details. This makes flashlights look great while staying functional. CNC machining helps you design flashlights that are useful and stylish.

Accurate and Consistent Parts Every Time

CNC machines ensure flashlight parts are made exactly right. They use advanced systems to keep production consistent. This prevents errors that could harm flashlight performance. For example, control charts check accuracy during production to fix problems early.

Manufacturers use tools like standard deviation to check for errors. This helps them fix mistakes and keep quality high. CNC machining also wastes less material, saving money and time. With CNC precision, every flashlight works as it should.

Benefit | Description |

|---|---|

Lower costs | Saves money during production. |

Reduced scrap levels | Wastes less material. |

Great agility | Quickly adjusts to new designs. |

Smoother workflow | Makes production faster and easier. |

Improved forecasting | Helps plan and use resources better. |

Reduced setting times | Speeds up machine setup. |

Shortened manufacturing lead times | Faster from design to finished product. |

Cost-Effectiveness in Production

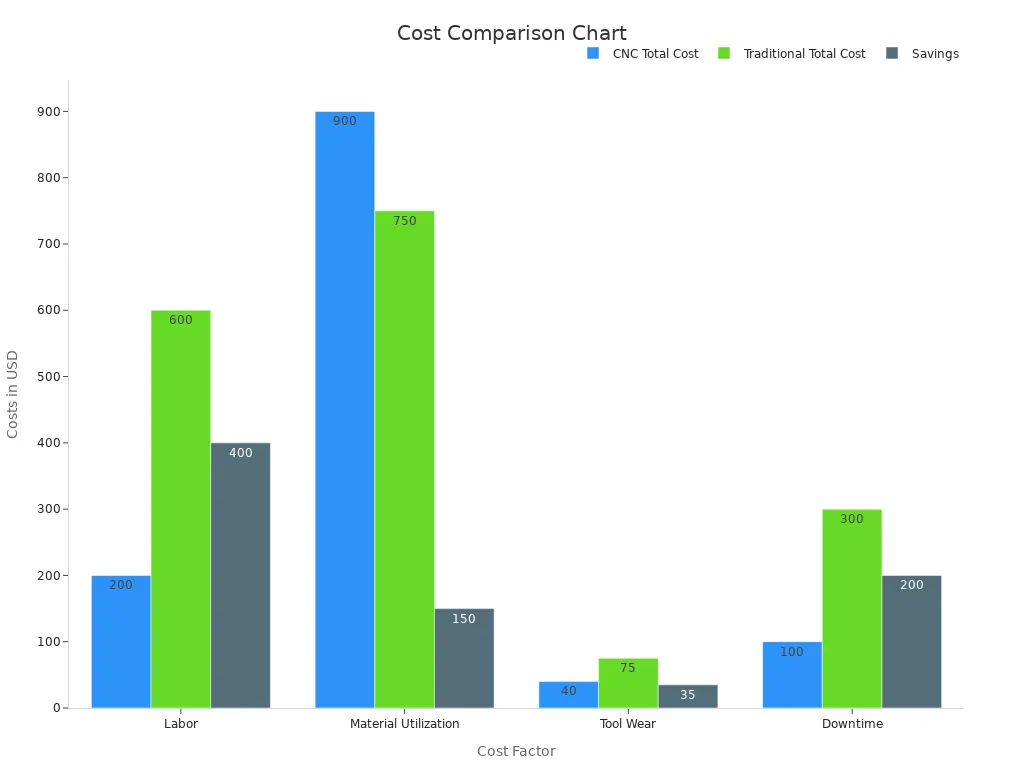

CNC machining helps save money when making flashlights. It uses machines to do tasks automatically, reducing mistakes and keeping quality high. This way, you get strong and reliable flashlights without spending too much.

One reason it saves money is by lowering labor costs. CNC machines need less human work, so fewer skilled workers are required. These machines also waste less material because they are very precise. For example, CNC machining uses materials wisely, leaving little scrap behind.

Another way it saves money is by cutting tool repair costs. CNC machines are built to run smoothly with less downtime. This means fewer repairs and replacements are needed. Faster production times also help manufacturers make flashlights quicker.

The table below shows how CNC machining costs compare to older methods:

Cost Factor | CNC Machining Total Cost | Traditional Machining Total Cost | Savings |

|---|---|---|---|

Labor | $200 | $600 | $400 |

Material Utilization | $900 (for 100 Kg) | $750 (for 100 Kg) | $150 |

Tool Wear | $40 | $75 | $35 |

Downtime | $100 | $300 | $200 |

Total | $1240 | $1725 | $785 |

The chart below shows these savings clearly:

Using CNC machining lowers costs while keeping quality high. It ensures flashlights are made with care, strength, and efficiency. This makes it a great choice for both companies and buyers.

Materials for CNC-Machined Flashlight Components

Aluminum for Lightweight Flashlight Shells

Aluminum is a top choice for flashlight shells. It is light, so carrying it is easy. Even though it’s light, aluminum is strong. This strength protects flashlights from damage if dropped. Its mix of lightness and strength makes it great for outdoor use, like camping.

Aluminum also resists rust naturally. This keeps flashlights durable in wet places. It’s simple to shape aluminum with CNC tools. This helps make detailed designs and smooth finishes. Many aluminum flashlights have anodized coatings. These coatings look nice and add extra protection.

Stainless Steel for Strength and Corrosion Resistance

Stainless steel is perfect for strong flashlight shells. It’s tougher than aluminum or brass. This makes it great for heavy-duty flashlights. If you use your flashlight a lot, stainless steel won’t bend or break.

Stainless steel also fights rust well. It stays clean and doesn’t stain in wet areas. Different types of stainless steel offer special benefits:

304: Resists rust and is easy to shape.

316: Resists rust even better, ideal for marine use.

CNC tools can shape stainless steel into strong flashlight shells. This ensures your flashlight works well in tough conditions.

Titanium for High-End Flashlight Designs

Titanium is the best for premium flashlight shells. It’s 45% lighter than steel but still very strong. Titanium can handle heavy impacts without breaking. This makes it great for extreme conditions.

Titanium also resists rust extremely well. It stays strong and looks good in harsh environments. CNC tools can shape titanium into sleek, durable designs. New technologies make titanium machining faster and easier. This helps create high-quality flashlights.

If you want a strong, light, and fancy flashlight, choose titanium.

Plastics for Affordable and Flexible Flashlight Shells

Plastics are a great choice for flashlight shells. They are cheap and can be shaped into many designs. Plastics are also lightweight, making flashlights easy to carry. CNC machines help make plastic parts very precise, so every shell fits perfectly.

One big benefit of plastics is their low cost. They are much cheaper than metals like aluminum or titanium. CNC machining saves even more money by reducing wasted material. These machines cut plastics carefully, using only what’s needed and lowering production costs.

Plastics are also very flexible for designs. You can make shells with cool patterns, comfy grips, or clear sections. CNC machines create detailed designs, making each flashlight shell look and work great. Plastics can also be colored or coated, giving lots of customization options.

The table below shows why plastics are great for flashlight parts:

Benefit | Description |

|---|---|

High accuracy | CNC machines make detailed and consistent parts for flashlights. |

Faster production | CNC automation speeds up making flashlight parts. |

Less waste and lower cost | Careful cutting saves material and reduces costs. |

Plastics are also strong and durable. New types of plastics can handle impacts, resist rust, and survive tough weather. This makes them perfect for flashlights used outdoors or daily. Whether for camping or home use, plastic shells are a smart and affordable choice.

By using plastics, you get a mix of low cost, flexibility, and strength. CNC machining makes these benefits even better, creating high-quality flashlight shells just for you.

Advanced CNC Tools and Techniques

Multi-Axis CNC Machines for Complex Flashlight Designs

Multi-axis CNC machines help make flashlights with detailed designs. These machines move tools in many directions for precise cuts. They can create shapes and patterns that older methods cannot. For example, curved patterns or fine engravings on flashlight shells are possible with these machines.

These machines also make parts that fit together perfectly. This ensures flashlights work well and look great. Multi-axis CNC machining is perfect for making special flashlight designs. It works for outdoor gear or professional tools.

Precision Cutting for Aesthetic and Functional Components

Precision cutting is important for making flashlight parts. It ensures every piece is the right size and shape. This improves how flashlights look and work. CNC machines use advanced tools to cut smoothly and evenly.

For looks, precision cutting adds polished surfaces or engraved logos. It can also create detailed patterns on flashlight shells. For function, it ensures threads and seals fit tightly. This prevents leaks or loose parts. CNC machining combines style and performance in flashlight design.

Automation for Efficiency and Scalability

Automation makes flashlight production faster and easier. Automated systems handle tasks like loading parts, saving time. Robots and tool changers make production quicker and more accurate. This helps create high-quality flashlights faster.

Machine vision systems check parts for defects automatically. This keeps quality consistent in every batch. Fully automated systems make scaling production simple and cost-effective.

Here’s a table showing automation benefits in CNC machining:

Key Point | Description |

|---|---|

Automation in CNC Machining | Automation speeds up production and reduces time per cycle. |

Cost Efficiency | Low-cost automation improves efficiency and saves money. |

Full Automation | Fully automatic systems handle loading and unloading parts. |

Automation also reduces waste and human mistakes. This makes CNC machining a smart choice for flashlight makers who want to grow their business without losing quality.

Tip: Using automation in CNC machining saves time and ensures great results. It’s a wise choice for making flashlights efficiently.

Applications of CNC Precision in Flashlight Customization

Flashlight Shells Made for Special Uses

CNC machining helps make flashlight shells for specific needs. Whether for hiking, work, or daily use, CNC ensures the design fits the job. Lightweight shells are great for hiking, while tough ones work well in factories. CNC tools shape materials like aluminum, steel, or titanium to match your needs.

You can also add useful features. Grooves improve grip, slots hold attachments, and seals keep water out. CNC machining makes these features accurate and dependable. Customizing flashlight shells improves performance and makes them last longer.

Unique Engravings for Personal Touch

Engravings make flashlights special and personal. CNC machines create detailed engravings like names, logos, or designs. This makes your flashlight unique and different from others. Many people enjoy having items that show their personality.

Studies show people want personalized products. Deloitte found 36% of buyers prefer custom items. Younger generations, like Millennials, love unique goods. CNC precision makes adding engravings easy and fun. Online tools let you design and preview engravings quickly.

Prototypes for Special and Small Markets

CNC machining is great for testing new flashlight ideas. It quickly makes prototypes for unique designs. This lets you check the flashlight before making more. For small markets, CNC machining is flexible. You can make a few flashlights without spending too much.

For example, you might need a flashlight for underwater use or medical tools. CNC machining ensures prototypes are correct and work well. This saves time and money, helping you create new flashlight designs easily.

CNC precision machining improves flashlight design with strength, flexibility, and savings. Aluminum is a great material because it’s light, easy to shape, and resists rust. These features make flashlights tough and dependable, even in hard conditions.

CNC machining works for many needs. It can make strong flashlights for outdoor trips or stylish ones for daily use. It ensures parts are always accurate and high-quality, perfect for custom or large-scale production.

If you want better flashlights, CNC precision machining helps turn your ideas into reality.

FAQ

Why is CNC machining better than older methods for flashlights?

CNC machining uses computers to guide tools for exact parts. Older methods can’t match this accuracy. CNC makes flashlight parts fit perfectly, boosting performance and strength. It also cuts down mistakes and speeds up making flashlights, making it the better choice.

Can CNC machining create custom flashlight designs?

Yes, CNC machining is great for custom designs. You can easily make special shapes, patterns, or engravings. It works with materials like aluminum, titanium, and plastics. This lets you design flashlights for specific uses or personal styles.

Is CNC machining good for small flashlight batches?

CNC machining works well for small batches. It wastes less material and lowers labor costs with automation. You can make top-quality flashlights without spending too much, which is perfect for small markets or testing new ideas.

What materials are best for CNC-made flashlights?

Aluminum, stainless steel, titanium, and plastics are top picks. Aluminum is light, steel is strong, titanium is high-end, and plastics are budget-friendly. Each material fits different needs, like outdoor use or stylish looks.

How does CNC machining make flashlights last longer?

CNC machining creates tightly fitting parts, removing weak spots. It avoids material flaws and makes flashlights stronger. This precision helps flashlights handle drops, hits, and tough conditions, making them last much longer.

Tip: Pick CNC machining for strong, custom, and affordable flashlight production. It ensures every flashlight is made with care and precision.

See Also

Utilizing CNC Machining for Outdoor and Tactical Flashlight Parts

Achieving Precision in Parts Manufacturing Through CNC Machining

Expert CNC Milling Services for Precision Engineering Solutions

Streamlined CNC Machining Services for High-Precision Production

Expert CNC Turning Techniques for Precision RC Component Design

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com