The Ultimate Guide to Different CNC Machine Types

CNC machines revolutionize manufacturing processes with their precision and automation capabilities. Understanding the diverse CNC machines available is crucial for optimizing production efficiency. This blog provides a comprehensive overview of various CNC machine types, shedding light on their functions, applications, and unique features. As the demand for precise components rises, the CNC industry is projected to grow significantly. By 2025, the global market is expected to exceed USD 100 billion, showcasing the immense potential of these advanced machines.

Types of CNC Machines

Pick and Place Machine

Pick and place machines offer high precision in component placement, ensuring each component is accurately positioned on the PCB according to the design specifications. These machines are versatile and can handle various component sizes, shapes, and types. They provide flexibility in production by allowing quick changeovers between different PCB designs.

Functions:

Precise component placement on PCBs

Handling various component sizes and shapes

Quick changeovers between different PCB designs

Common Uses:

Efficient PCB assembly

Cost-effective production of electronic devices

Streamlining the manufacturing process

Unique Features:

Versatility in handling different components

High precision in placement

Quick changeover capabilities for diverse PCB designs

3D Printer

3D printers have revolutionized prototyping and manufacturing processes by enabling the creation of three-dimensional objects from digital files. They offer a wide range of applications across various industries, from rapid prototyping to custom product development.

Functions:

Creating three-dimensional objects from digital files

Rapid prototyping capabilities

Custom product development

Common Uses:

Prototyping in product design

Customized manufacturing processes

Architectural modeling

Unique Features:

Layer-by-layer additive manufacturing process

Diverse material compatibility for printing objects

Precision in creating complex geometries

Router CNC Machine

Router CNC machines are essential tools for cutting and shaping materials with precision and accuracy. They utilize computer-controlled movements to carve intricate designs on various surfaces, making them ideal for woodworking, metalworking, and other fabrication tasks.

Functions:

Cutting and shaping materials with precision

Carving intricate designs on surfaces

Computer-controlled movements for accuracy

Common Uses:

Woodworking projects

Metal fabrication tasks

Engraving detailed patterns

Unique Features:

Computer-guided cutting paths

Multi-axis movement capabilities

Compatibility with a wide range of materials

Drilling CNC Machine

Functions

Drilling CNC machines are specialized tools designed to create holes in various materials with precision and efficiency.

These machines utilize computer-controlled movements to accurately position the drill bit and control the depth of each hole.

By automating the drilling process, they ensure consistent hole sizes and placements, enhancing overall productivity.

Common Uses

Manufacturing Industry: Drilling CNC machines play a crucial role in the manufacturing sector for creating precise holes in metal, plastic, and other materials.

Woodworking Applications: They are also widely used in woodworking to produce accurate boreholes for joinery and assembly purposes.

Construction Sector: In construction, these machines aid in drilling holes for electrical wiring, plumbing installations, and anchor bolts.

Unique Features

Automatic Tool Changer: Some drilling CNC machines come equipped with automatic tool changers that allow for seamless transitions between different drill bits.

Variable Speed Control: The ability to adjust drilling speeds ensures optimal performance when working with various materials.

Precision Depth Control: These machines offer precise depth control mechanisms to achieve consistent hole depths based on specific requirements.

Lathe CNC Machine

Functions

Lathe CNC machines are essential for shaping cylindrical workpieces by rotating them against cutting tools.

They enable turning operations such as facing, grooving, threading, and tapering with high accuracy.

The computerized controls of these machines ensure uniform cutting movements for smooth surface finishes.

Common Uses

Metal Fabrication: Lathe CNC machines are extensively used in metal fabrication processes to create intricate parts like shafts, bushings, and pulleys.

Automotive Industry: They play a vital role in manufacturing automotive components such as crankshafts, camshafts, and wheel hubs.

Aerospace Sector: In aerospace engineering, lathe CNC machines produce precision parts for aircraft engines and structural components.

Unique Features

Live Tooling Capabilities: Some lathe CNC machines offer live tooling options that allow for milling operations during the turning process.

Multi-Axis Machining: Advanced models feature multi-axis capabilities for complex geometries and contours on workpieces.

Bar Feeder Integration: Automation features like bar feeders enhance productivity by continuously feeding raw material into the machine.

5-Axis CNC Machine

Functions

5-axis CNC machines provide enhanced versatility by enabling machining operations along five axes of motion.

This allows for complex cuts from multiple angles without repositioning the workpiece manually.

The simultaneous movement capability enhances efficiency and accuracy in producing intricate components.

Common Uses

Prototyping Applications: 5-axis CNC machines are ideal for rapid prototyping of complex parts with intricate designs.

Medical Device Manufacturing: They are utilized in producing medical implants with precise dimensions and intricate features.

Tool & Die Making: In tooling industries, these machines craft molds and dies with intricate shapes efficiently.

Unique Features

Continuous Rotary Motion: The rotational axis enables continuous cutting around all sides of a workpiece without repositioning it manually.

Collision Detection Systems: Advanced 5-axis CNC machines incorporate collision detection systems to prevent tool interference during operation.

High-Speed Machining Capabilities: These machines offer high-speed machining options for increased productivity while maintaining precision levels.

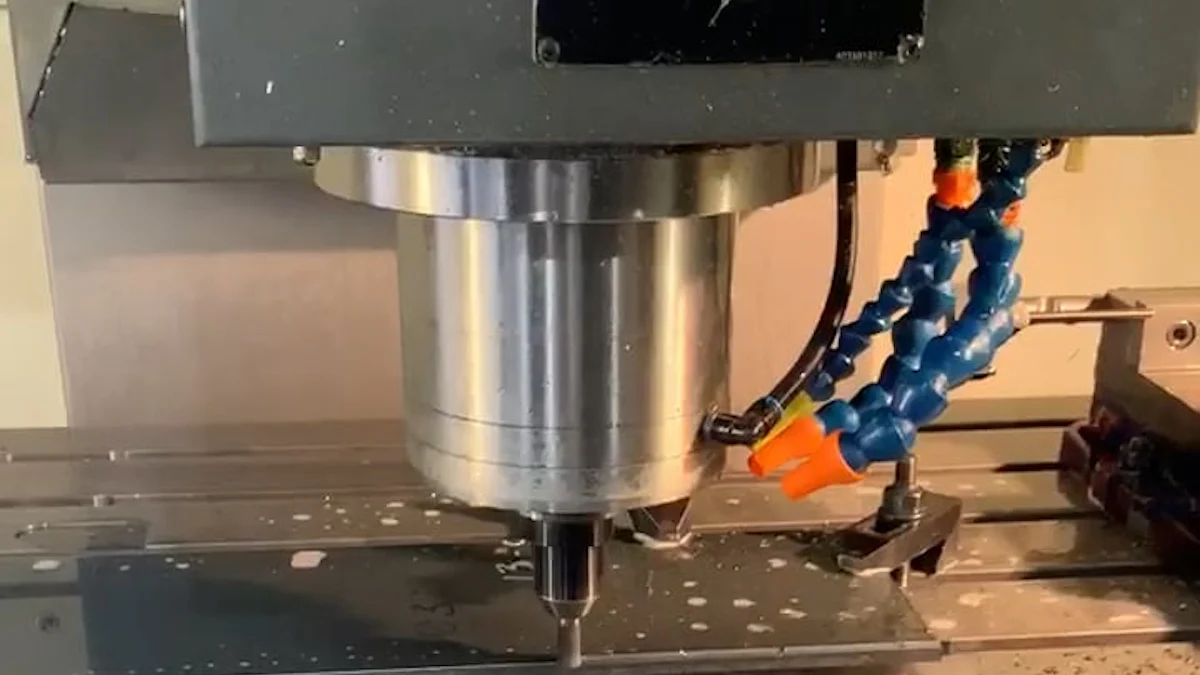

CNC Milling Machine

Functions

CNC milling machines are pivotal in the manufacturing industry for shaping solid materials. They operate by removing material from a workpiece through rotary cutters, resulting in intricate shapes and designs.

These machines utilize computer numerical control to precisely control the cutting process, ensuring accuracy and repeatability in production.

CNC milling machines can perform various operations such as drilling, tapping, and slot cutting with high efficiency.

Common Uses

Prototyping: CNC milling machines are extensively used in rapid prototyping to create initial models of products for testing and evaluation.

Production Manufacturing: They play a crucial role in mass production processes by consistently producing components with tight tolerances.

Customization: CNC milling machines enable the customization of parts according to specific design requirements, catering to diverse industry needs.

Unique Features

Rotary Cutters: The use of rotary cutters allows CNC milling machines to achieve complex shapes and contours on workpieces effectively.

Vertical and Horizontal Configurations: These machines come in both vertical and horizontal versions, providing flexibility in machining different types of materials.

Tool Changers: Some advanced CNC milling machines feature automatic tool changers that enhance operational efficiency by reducing downtime during tool changes.

CNC Plasma Cutters

Functions

CNC plasma cutters are instrumental in cutting through electrically conductive materials using a high-velocity jet of ionized gas. This process results in precise cuts with minimal heat distortion.

These machines operate by generating an electrical arc that passes through the gas stream, creating a plasma jet capable of melting metal and expelling it from the workpiece.

Common Uses

Metal Fabrication: CNC plasma cutters are widely employed in metal fabrication industries for cutting steel, aluminum, and other metals with speed and accuracy.

Artistic Applications: Artists utilize these machines to create intricate metal artworks due to their ability to produce detailed cuts on various metal surfaces.

Industrial Maintenance: In industrial settings, CNC plasma cutters aid in repairing or modifying metal components efficiently.

Unique Features

High Cutting Speeds: The high-velocity plasma jet allows CNC plasma cutters to swiftly cut through thick metal sheets without compromising precision.

Minimal Heat Affected Zone: By utilizing ionized gas for cutting, these machines produce minimal heat affected zones on the workpiece, preserving material integrity.

Multi-Axis Cutting Capabilities: Advanced CNC plasma cutters offer multi-axis cutting options that enable beveling and chamfering operations for intricate designs.

CNC Laser Cutting Machines

Functions

CNC laser cutting machines employ a focused laser beam to melt or vaporize material from a workpiece, resulting in precise cuts with smooth edges. This non-contact process is ideal for delicate materials.

Common Uses

Sheet Metal Fabrication: Industries rely on CNC laser cutting machines for precise sheet metal cutting operations used in various applications like automotive manufacturing and aerospace engineering.

Signage Production: Sign-making companies utilize these machines to create custom signs with intricate designs quickly and accurately.

Jewelry Manufacturing: In jewelry production, CNC laser cutting machines offer precision cutting capabilities for crafting intricate pieces with fine details.

Unique Features

High Precision Cuts: The focused laser beam ensures unparalleled precision when operating CNC laser cutting machines on different materials.

Non-contact Cutting Process: By utilizing a non-contact method, these machines prevent physical distortion or damage to delicate workpieces during the cutting process.

Versatile Material Compatibility: CNC laser cutting machines can efficiently cut through various materials such as metals, plastics, wood, and composites with ease.

CNC Electrical Discharge Machines (EDM)

Functions

CNC Electrical Discharge Machines (EDM) are advanced tools used for precision machining operations. These machines utilize electrical discharges to remove material from the workpiece, ensuring intricate shapes and designs are achieved with high accuracy. The EDM process involves creating sparks between the electrode and the workpiece, eroding the material to produce the desired shape.

High Precision Machining: CNC EDM machines excel in producing complex geometries with tight tolerances, making them ideal for applications requiring utmost precision.

Material Removal: By using electrical discharges, these machines can efficiently remove material from conductive workpieces without causing mechanical stress.

Intricate Shape Creation: CNC EDM machines enable the creation of intricate shapes that may be challenging to achieve with traditional cutting methods.

Common Uses

Tool and Die Making: CNC EDM machines are extensively used in tool and die making industries for producing molds, dies, and other tooling components with exceptional precision.

Aerospace Engineering: In aerospace applications, these machines craft critical components like turbine blades and engine parts that demand precise machining processes.

Medical Device Manufacturing: The medical industry utilizes CNC EDM machines to create intricate components for surgical instruments and implants due to their high precision capabilities.

Unique Features

Non-contact Machining: Unlike traditional cutting methods, CNC EDM machines operate without direct contact between the tool and the workpiece, minimizing wear on cutting tools.

Submerged Cutting: Some CNC EDM machines feature submerged cutting capabilities where the workpiece is immersed in dielectric fluid during machining to enhance efficiency and precision.

Wire EDM Technology: Wire EDM is a specialized form of CNC EDM that uses a thin wire as an electrode to cut through the workpiece with extreme accuracy.

Summarizing the diverse CNC machine types discussed reveals a vast array of capabilities across industries. Each machine, from Pick and Place to 5-Axis CNC, offers unique functions and applications that cater to specific manufacturing needs.

Choosing the right CNC machine is paramount for achieving precision and efficiency in production processes. The advanced technology integrated into these machines ensures high-quality output with minimal errors, enhancing overall productivity.

Future trends in CNC technology point towards increased automation, improved precision, and enhanced versatility. As industries evolve, CNC machines will continue to play a pivotal role in shaping the manufacturing landscape.

In conclusion, embracing the advancements in CNC technology is essential for staying competitive in the ever-evolving manufacturing sector. By leveraging the capabilities of different CNC machines, businesses can streamline operations and meet the demands of a rapidly changing market.

See Also

A Comprehensive Guide to Precision CNC Manufacturing Techniques

Mastering CNC Milling: A Complete Overview of Services

Beginner's Guide to CNC Technology: An In-depth Look

Discovering Precision Engineering through CNC Milling Exploration

Becoming a CNC Machining Expert: Technical Drawing and Material Tips

About US

Follow Us

Your prototype holds unparalleled significance, and we deeply value its uniqueness. Collaborating with you during the preparation phase for running your prototype or parts is a commitment we gladly embrace. Whether it's a single part or a complex assembly, we are dedicated to selecting the optimal tools and pathways to bring your envisioned product to life.

At Precision Fab CNC Machining, we specialize in producing parts for prototypes, short runs, and high-volume production. Our prototyping machine capabilities extend across metal, plastic, and wood machining, with welding fabrication services available to complement and finalize your prototype if required.

Address

Address: Room320 10F, Building A,Nanshan international building, Dayawan District, Huizhou, Guangdong, 516001 China

Contacts

billy@timaycnc.com